Modüler Kırlangıç Kuyruğu Fikstürü

52 & 96 Sistemleri için Rijit 5 Yüzey Bağlama

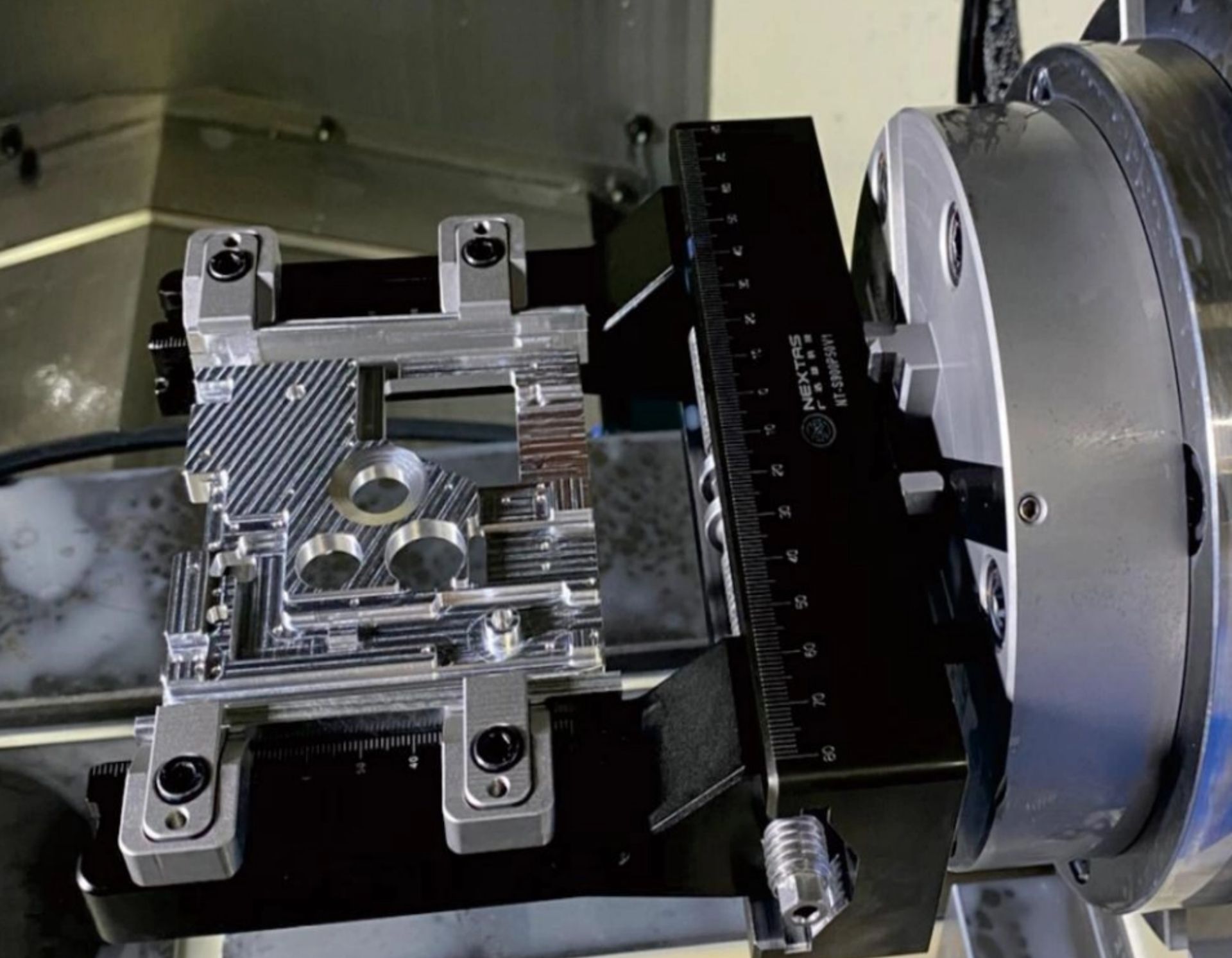

Yüksek hızlı beş eksenli işleme için tasarlanan Nextas kırlangıç kuyruğu fikstürü, iş parçasını küçük bir 45° profil üzerinden güvenli bir şekilde kavrar. Bu sayede, malzeme israfını en aza indirirken işleme için beş yüzeyi açığa çıkarır. Hassas konumlama pimleri tekrarlanabilir pozisyonlama sağlarken, modüler 52 / 96 mm taban, yıldırım hızında kurulumlar için sıfır noktası plakaları ve hızlı değiştirme sistemleriyle sorunsuz bir şekilde entegre olur.

Temel Avantajlar

- 5 Yüzey İşleme Erişimi: Minimum 45° kırlangıç kuyruğu profilinde stoğu kavrayarak işleme için beş yüzeyi serbest bırakır, böylece kurulum başına daha fazla parça işlenir ve malzeme israfı azalır.

- Üstün Sıkma Kuvveti: 45° kırlangıç kuyruğu tasarımı, yüksek sıkma kuvveti ve rijit stabilite sağlayarak kesme titreşimlerine karşı direnç gösterir ve kaymayı önler.

- Yüksek Hassasiyet ve Tekrarlanabilirlik: Hassas konumlama pimleri ve taşlanmış yüzeyler, tekrarlanabilir konumlandırma sağlar ve iş parçası hareketini ortadan kaldırır.

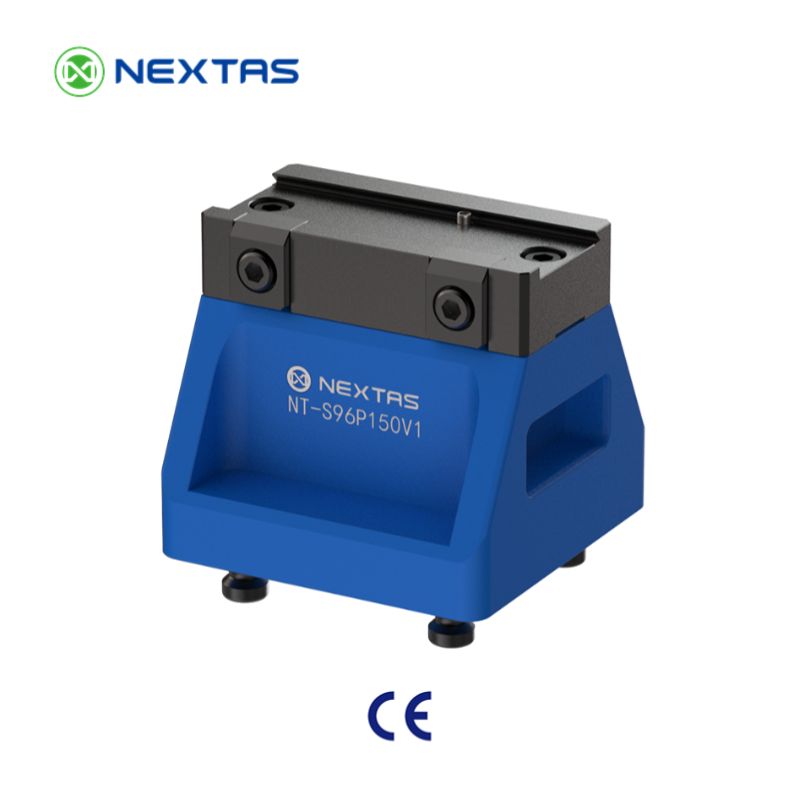

- Modüler 52 / 96 Entegrasyonu: Standart 52 mm ve 96 mm şablonlar, esnek montaj ve hızlı değişimler için sıfır noktası sistemleri ve hızlı değiştirme plakalarıyla entegre olur.

- Hafif ve Dayanıklı: Paslanmaz çelik ek parçalara sahip havacılık sınıfı alüminyum gövde, yüksek mukavemet, azaltılmış ağırlık ve uzun süreli stabilite sağlar.

- Çok Yönlü ve Otomasyona Hazır: Geniş bir malzeme yelpazesini destekler; hızlı kurulumlar ve kompakt yapısı sayesinde yüksek çeşitlilikli (high-mix) üretim ve robotik otomasyon için idealdir.

Teknik Özellikler

Hem 52 mm hem de 96 mm kırlangıç kuyruğu fikstürleri, endüstri standardı sıfır noktası montaj şablonlarına uygundur. Ayrıntılı teknik çizimler hızlı başvuru için aşağıda verilmiştir.

5 Yüzey İşleme Verimliliği

Kırlangıç kuyruğu fikstürü, iş parçasını küçük bir 45° kırlangıç kuyruğu boyunca kavrayarak üst, ön, arka ve iki yan yüzeyi kesme işlemi için tamamen engelsiz bırakır. Bu tasarım, tek bir kurulumda gerçek 5 yüzey işlemeyi mümkün kılar ve normalde kavrama için gereken ekstra malzemeyi azaltarak hem zamandan hem de hammadde maliyetlerinden tasarruf sağlar.

Hassasiyet ve Tekrarlanabilirlik

Her bir kırlangıç kuyruğu fikstürü, kaymayı önlemek ve parça değişimi sırasında yüksek tekrarlanabilirlik sağlamak için hassas konumlama pimleri ve taşlanmış referans yüzeyleri ile donatılmıştır. Rijit kırlangıç kuyruğu geometrisi ile birleştiğinde, bu özellik tutarlı işleme doğruluğu ve yüzey kalitesini garanti eder.

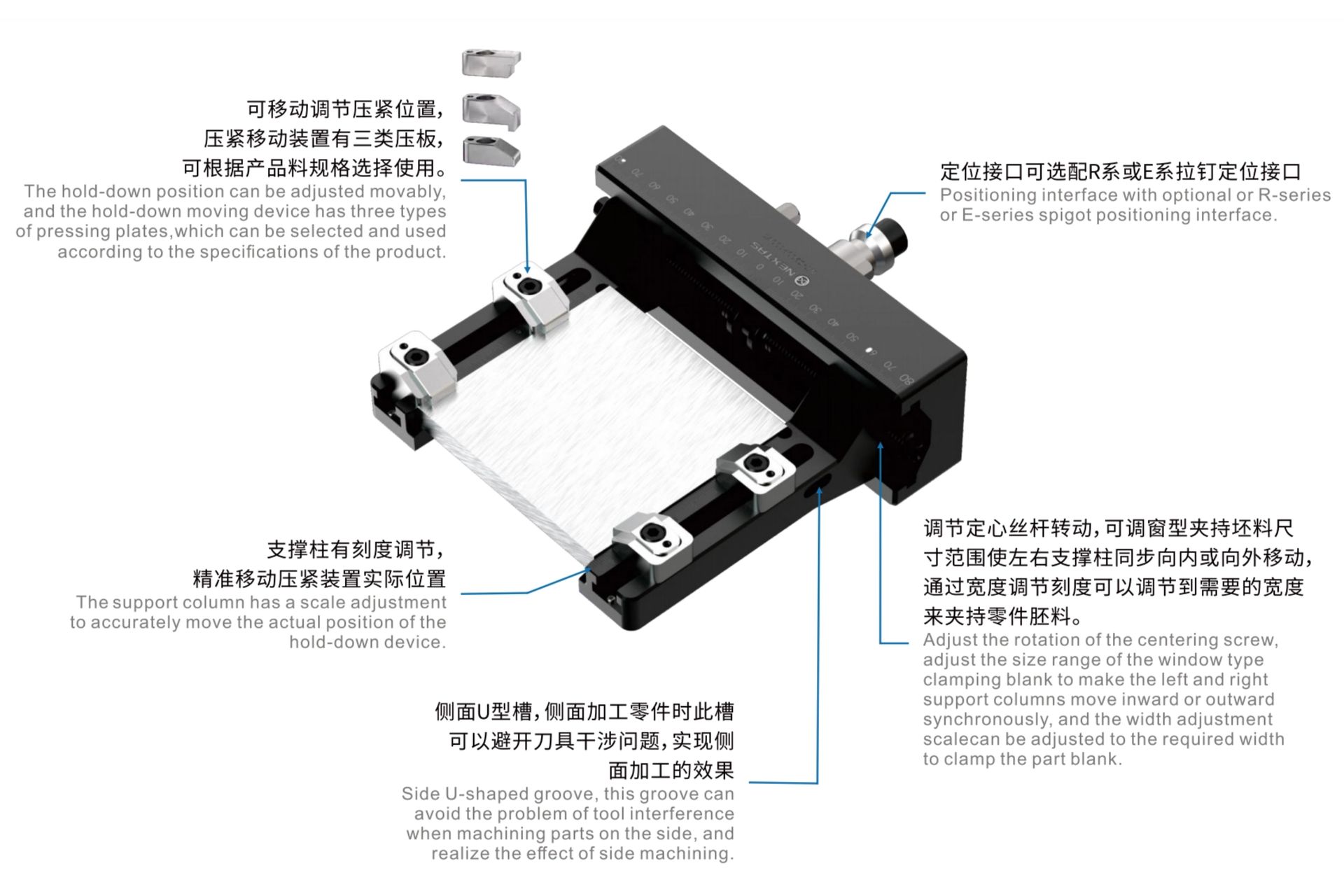

- 3/4/5 eksenli makinelerde küçük parça işleme için patentli tasarım.

- Seçilebilir baskı plakaları ile ayarlanabilir sıkma konumu.

- Hassas tutma yerleşimi için ölçek ayarlı destek kolonu.

- Yan yüzey işleme sırasında takım çarpışmasını önleyen yan U-şekilli oluk.

- Opsiyonel 3R veya Erowa pim (spigot) konumlama arayüzleri.

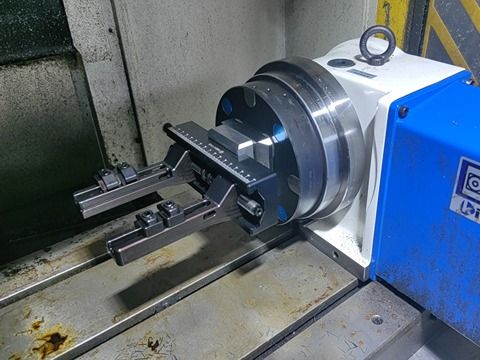

Modüler ve Sıfır Nokta Uyumlu

Fikstürün tabanı, endüstri standardı 52 mm ve 96 mm şablonlarına göre işlenmiştir; bu da onu sıfır noktası bağlama plakaları, hızlı değiştirme sistemleri ve otomasyon paletleriyle doğrudan uyumlu hale getirir. Bu modülerlik, kurulum değişimlerini kolaylaştırır ve artan verim için birden fazla fikstürün yüksek yoğunluklu diziler halinde monte edilmesine olanak tanır.

Uygulamalar ve Kullanım Alanları

Vaka Çalışması: Endüstriyel Otomasyon

Kırlangıç kuyruğu fikstürü, pnömatik sıfır noktası plakasıyla sorunsuz bir şekilde eşleşerek endüstriyel otomasyonda ince levha ürünlerin hızlı ve hassas bir şekilde bağlanmasını sağlar. Kurulum süresini ciddi oranda azaltır, kararlı işleme sağlar ve işleme verimliliğini %30'un üzerinde artırır.

Karmaşık 5 Eksenli İşleme

Tam yüzey erişimi gerektiren titanyum ve havacılık parçaları için idealdir. Kırlangıç kuyruğu fikstürü beş yüzeyi açığa çıkararak, yeniden konumlandırma gerektirmeden tek bir kurulumda karmaşık özelliklerin işlenmesine olanak tanır.

Hızlı Değişim ve Otomasyon

Standart 52 / 96 mm montaj şablonları ile fikstürler, yıldırım hızında değişimler için sıfır noktası plakalarına oturur. Tam otomatik, yüksek yoğunluklu üretim hatları için robotik palet değiştiricilerle birleştirin.

Malzeme Çok Yönlülüğü

Alüminyumdan sertleştirilmiş çeliğe kadar, kırlangıç kuyruğu fikstürü çeşitli malzemeleri güvenli bir şekilde tutar. Dengeli tasarımı bozulmayı (distorsiyonu) azaltır ve hem prototipleme hem de seri üretim için mükemmel hale getirir.

Sıkça Sorulan Sorular

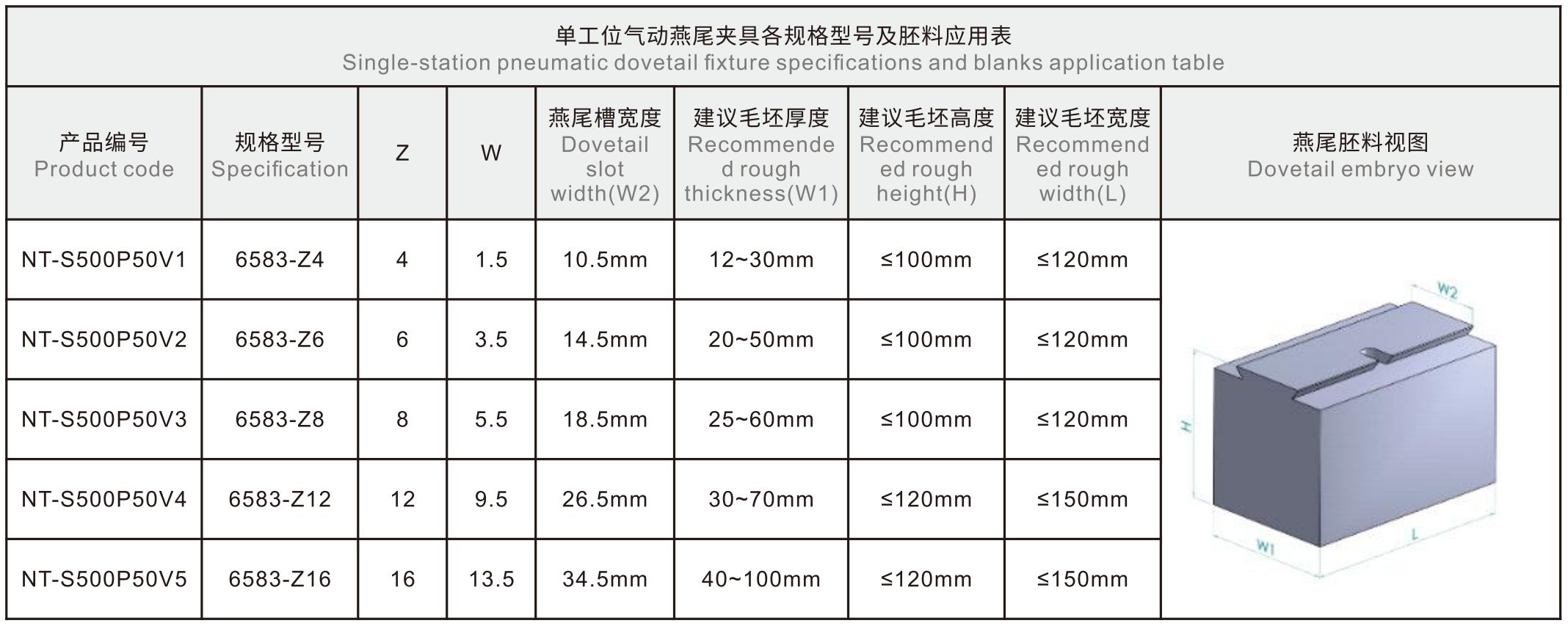

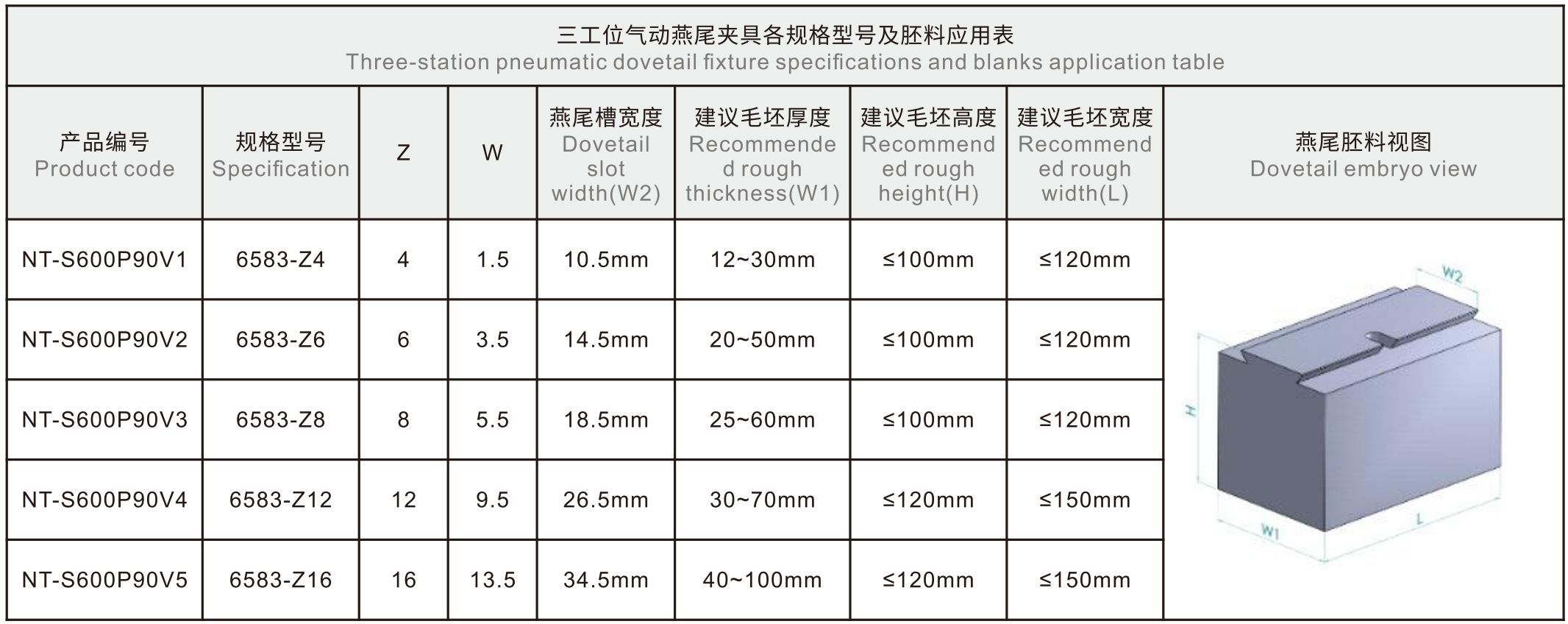

45° kırlangıç kuyruğu için ne kadar malzeme hazırlamam gerekir?

52 mm ve 96 mm kırlangıç kuyruğu fikstürleri arasındaki temel fark nedir?

Bu kırlangıç kuyruğu fikstürlerini 3 veya 4 eksenli makinelerde kullanabilir miyim?

Bu fikstürün 5 yüzey işleme için kendinden merkezlemeli mengeneye kıyasla farkı nedir?

Bu fikstürler ne tür bir bakım gerektirir?

Sıkma bileşenleri ve konumlama pimleri değiştirilebilir mi?

İlgili Ürünler

E-Serisi Ayna

Geniş bir otomatik tornalama uygulamaları yelpazesi için çok yönlü ve hassas ayna.

Detayları Gör →

R-Serisi Ayna

Ağır hizmet tipi tornalama ve frezeleme operasyonları için güçlü ve tutarlı sıkma sağlar.

Detayları Gör →

Otomatik Palet Değiştirici

Tam otomatik palet değişimleri ile kurulum süresini ciddi oranda azaltın ve makine çalışma süresini artırın.

Detayları Gör →