Hochpräziser 5-Achs-Zentrischspanner

Entwickelt für 5-Achs-Technik & Automation

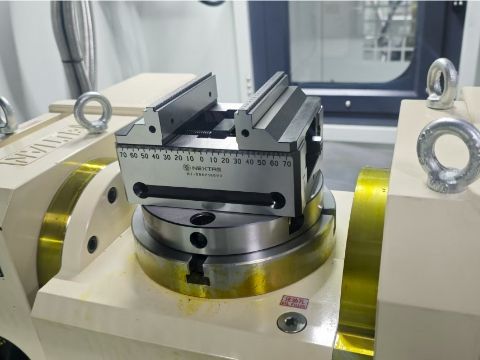

Der Nextas Zentrischspanner ist die ultimative Spannlösung für die moderne 5-Achs-Bearbeitung und automatisierte Produktion. Sein innovatives Design bietet außergewöhnliche Spannsteifigkeit und hohe Wiederholgenauigkeit, während die kompakte Bauform Störkonturen minimiert und den Werkzeugzugang zum Werkstück maximiert. Ein Eckpfeiler für jedes Unternehmen, das Effizienz und Präzision steigern möchte.

Kernvorteile

- Hohe Wiederholgenauigkeit: Garantiert eine Zentriergenauigkeit von — ,01 mm und eine Spannwiederholgenauigkeit von — ,02 mm für konsistente, hochwertige Ergebnisse.

- Kraftvolles & Stabiles Spannen: Der einzigartige Mechanismus liefert starke und stabile Haltekräfte (bis zu 35 kN), geeignet für Schwerzerspanung.

- Optimiert für 5-Achs: Kompaktes, symmetrisches Design minimiert Werkzeuginterferenzen und bietet maximale Zugänglichkeit für die Bearbeitung komplexer Teile.

- Bereit für Automation: Verfügt über Greifnuten für Roboter und ist kompatibel mit Nullpunktspannsystemen für schnelle, automatisierte Wechsel.

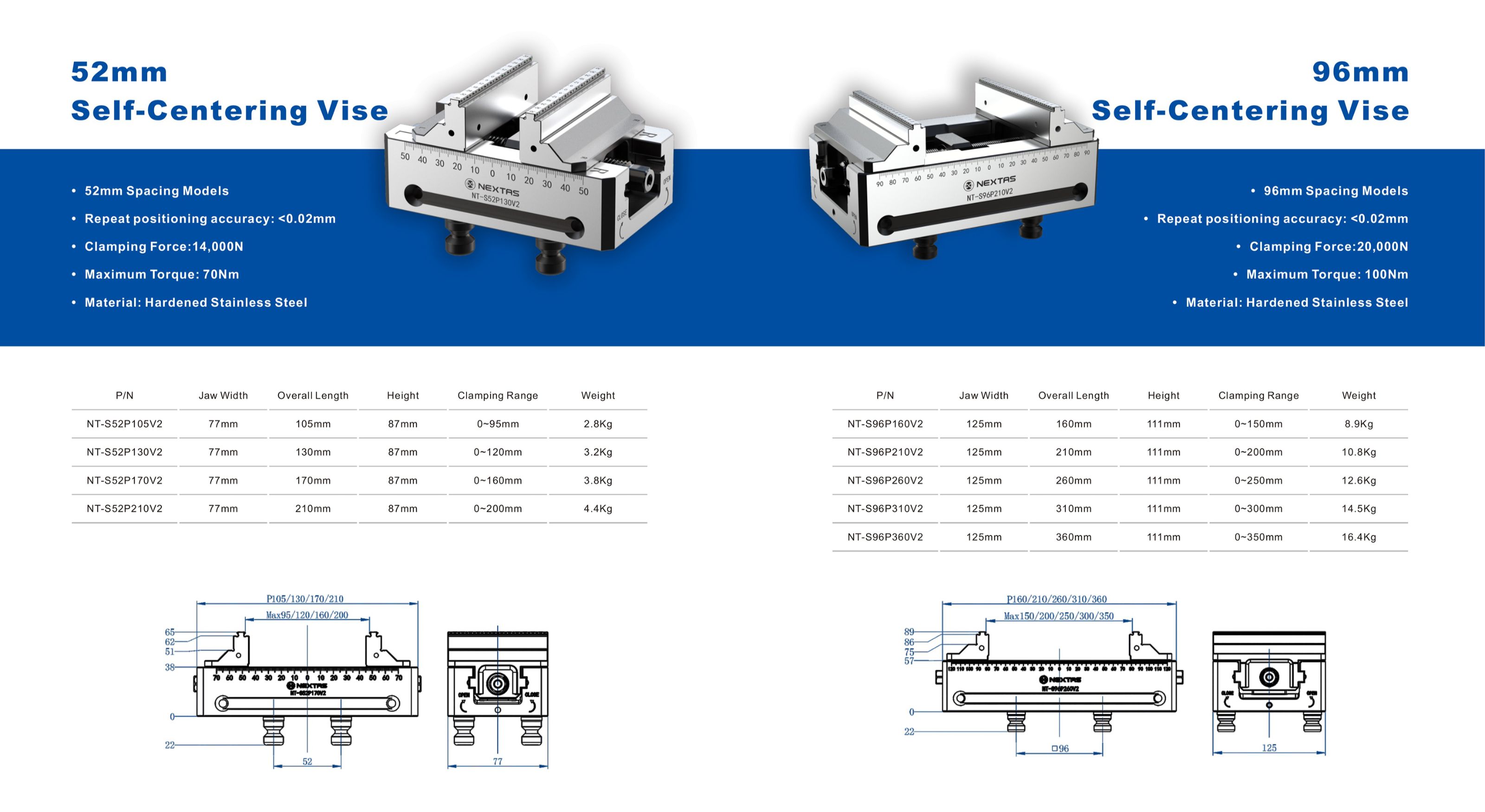

Detaillierte Produktinformationen

Entdecken Sie die technische Exzellenz hinter unserem Zentrischspanner.

Wichtige technische Daten

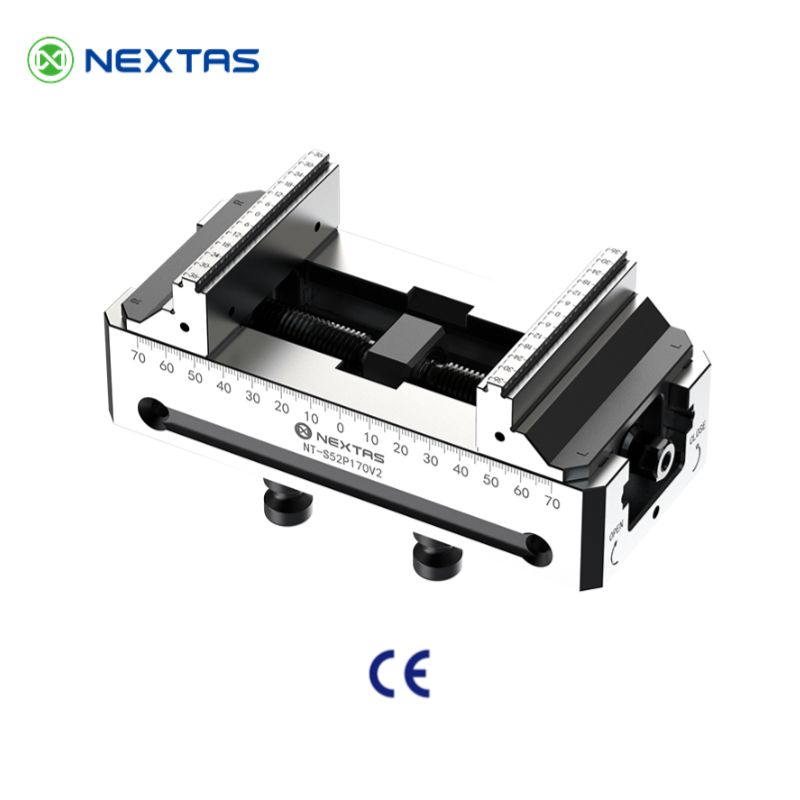

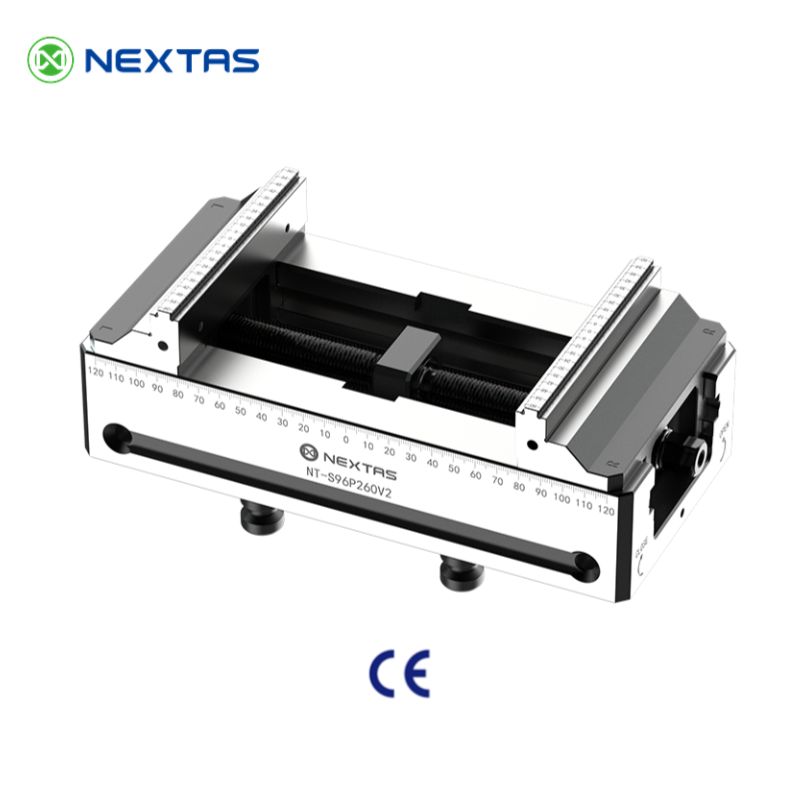

| Parameter | Modell: NT-S52P170V2 | Modell: NT-S52P210V2 |

|---|---|---|

| Backenbreite | 77 mm | 125 mm |

| Max. Spannbereich | 0 - 160 mm | 0 - 200 mm |

| Max. Spannkraft | 14 kN | 20 kN |

| Wiederholgenauigkeit | ±0,02 mm | ±0,02 mm |

| Grundkörpermaterial | Hochfester Werkzeugstahl (HRC 50?5) | Hochfester Werkzeugstahl (HRC 50?5) |

| Betätigung | Manuell (Drehmomentschlüssel) | Manuell (Drehmomentschlüssel) |

| Gewicht | 3,8 kg | 10,8 kg |

Backenspezifikationen & Spannbereiche

| Backentyp | Spannbereich (NT‑S52P170V2) | Spannbereich (NT‑S52P210V2) |

|---|---|---|

| Standardbacken | 10 - 170 mm | 20 - 210 mm |

| Grip-Backen (gezahnt) | 20 - 180 mm | 30 - 220 mm |

| Prismenbacken (V-Jaws) | Ø 10 - 100 mm | Ø 20 - 150 mm |

Entwickelt für Präzision und Effizienz

Der Nextas Zentrischspanner ist ein Eckpfeiler der modernen CNC-Bearbeitung. Wir verwenden hochfesten legierten Stahl, präzisionsgeschliffen und wärmebehandelt, um maximale Steifigkeit und Langlebigkeit zu gewährleisten. Sein zentraler Zentriermechanismus, angetrieben von einer hochpräzisen Gewindespindel, garantiert, dass das Werkstück während des Spannens perfekt zentriert bleibt — entscheidend für Teile, die eine hochpräzise symmetrische Bearbeitung erfordern.

Modularität und Flexibilität

Unser Spannsystem unterstützt eine breite Palette von Standard- und Sonderbacken und bietet so die optimale Spannlösung für alles, von Rohteilen bis hin zu fertigen Werkstücken. Das Backen-Schnellwechselsystem ermöglicht es Ihnen, Ihre Konfiguration in wenigen Minuten zu ändern, was die Rüstzeit drastisch reduziert und die Maschinenlaufzeit erhöht.

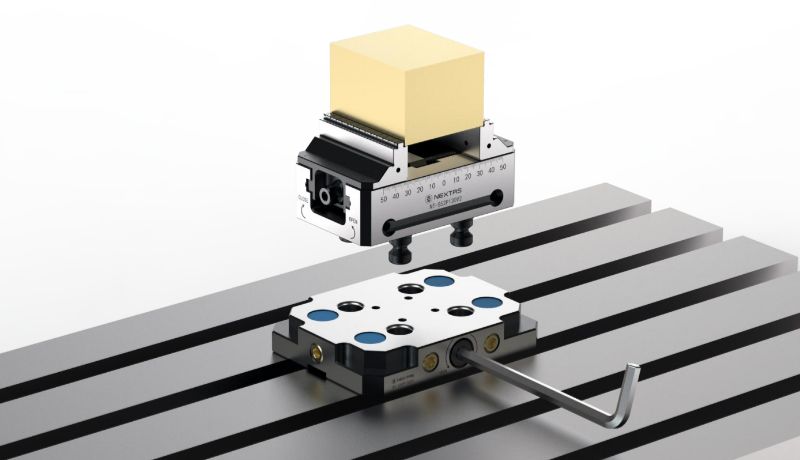

Felsenfest und Stabil

Die Basis des Spanners ist für die nahtlose Kompatibilität mit unseren Nullpunktspannsystemen ausgelegt und ermöglicht eine schnelle und präzise Montage. Einmal installiert, bildet der Spanner eine starre Einheit mit dem Maschinentisch und dämpft Vibrationen auch unter Hochgeschwindigkeits-Schnittbedingungen effektiv, um eine überlegene Oberflächengüte und Maßgenauigkeit zu gewährleisten.

Optimierte Zugänglichkeit

Das kompakte und stromlinienförmige Design bietet maximale Zugänglichkeit zum Werkstück, insbesondere bei komplexen 5-Achs-Bearbeitungsoperationen. Dies ermöglicht kürzere Werkzeuglängen, was Vibrationen reduziert und die Schnittleistung verbessert.

Technische Zeichnungen

Detaillierte Zeichnungen und Spezifikationen für die Integration.

Anwendungsbeispiele & Lösungen

Sehen Sie unseren Spanner im Einsatz in verschiedenen Branchen und Setups.

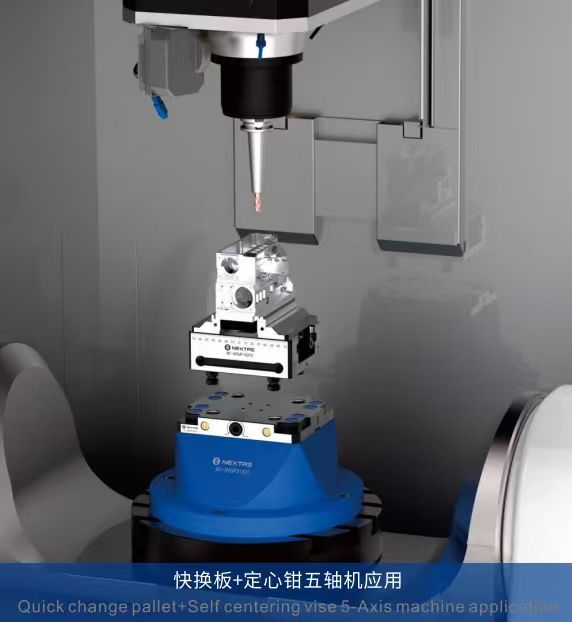

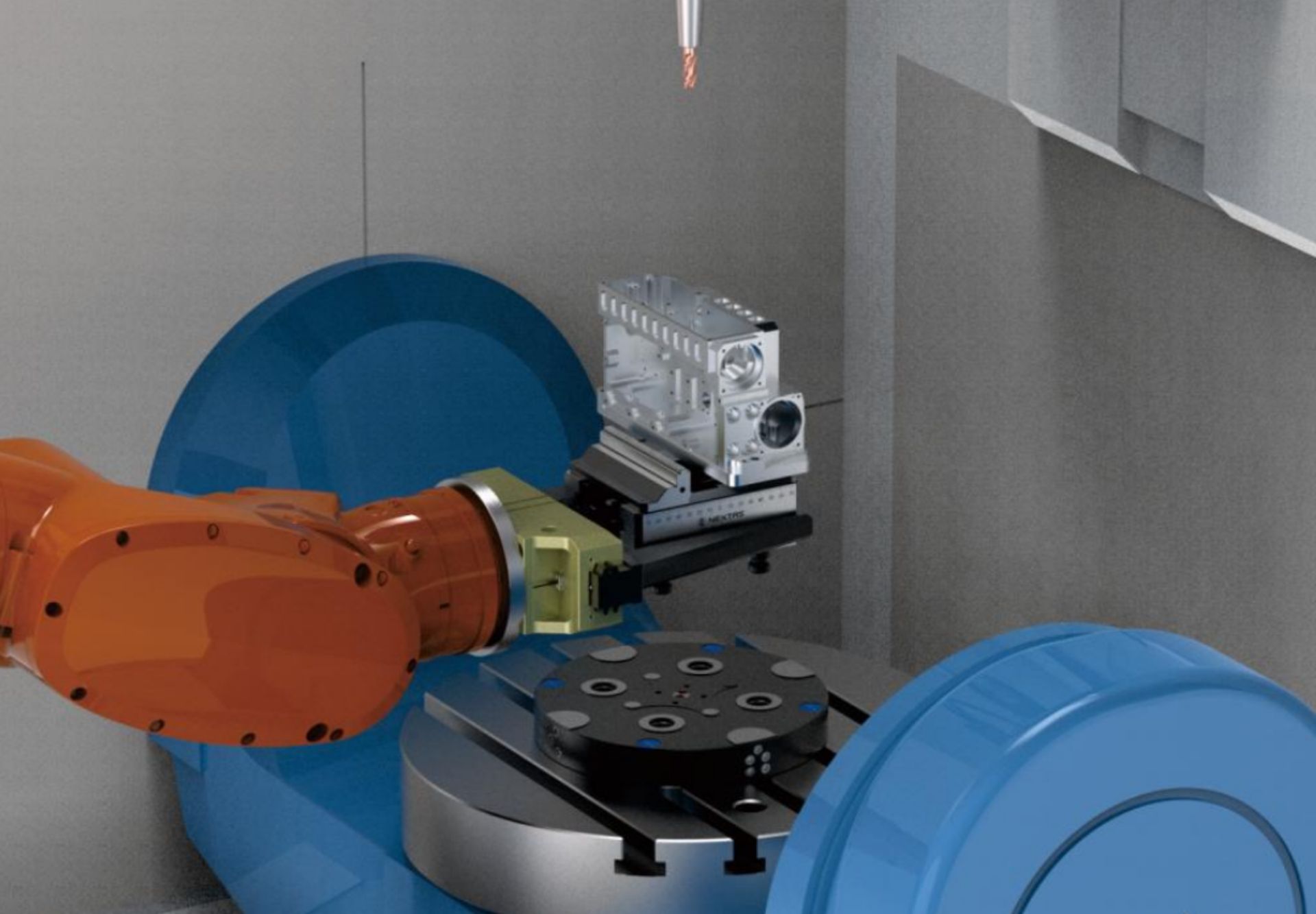

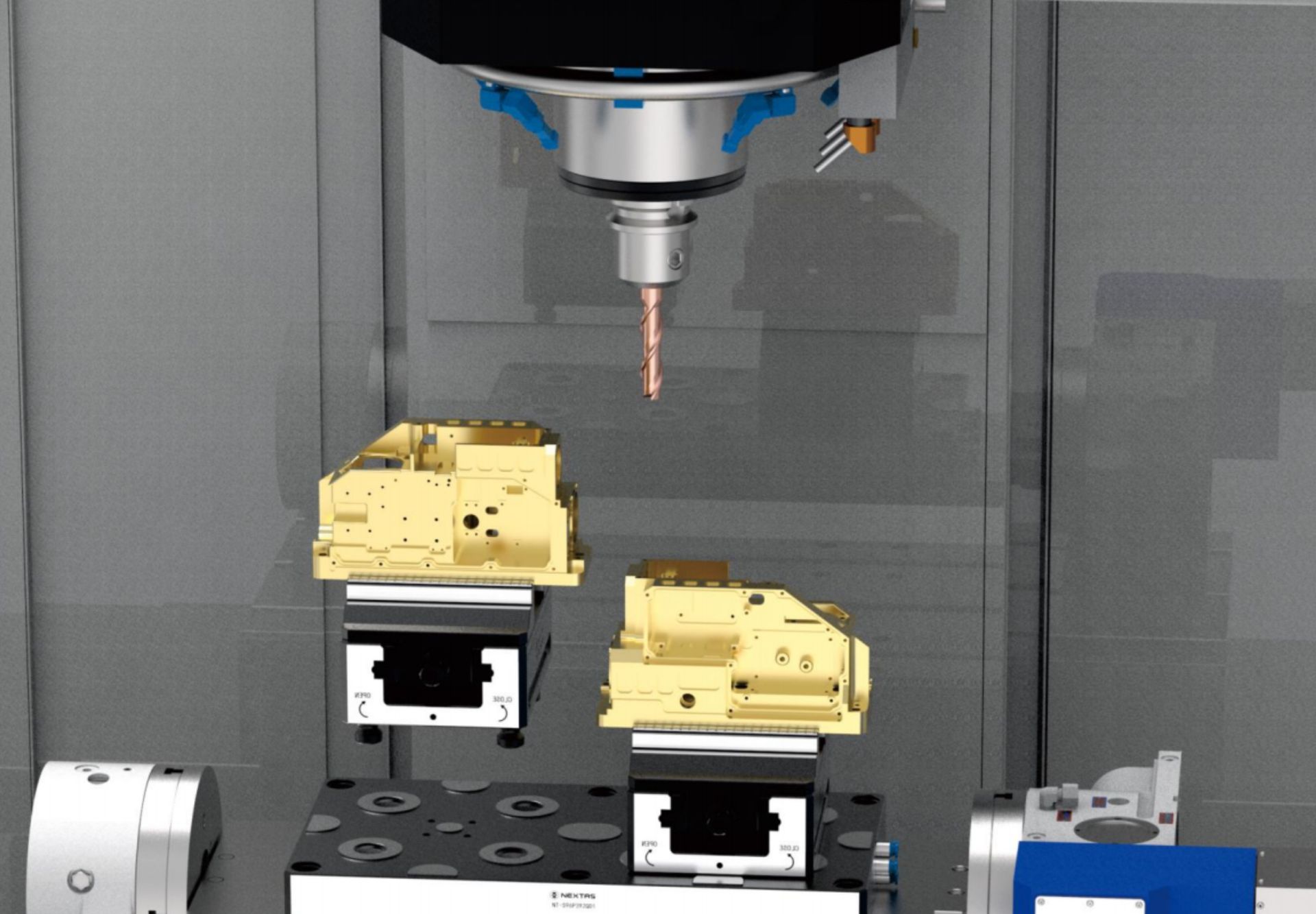

5-Achs-Simultan- & Komplexe Oberflächenbearbeitung

Das kompakte Design des Nextas Zentrischspanners bietet exzellenten Werkzeugzugang für die 5-Achs-Bearbeitung. Ob für Impeller, Formen oder komplexe Strukturbauteile, er gewährleistet eine störkonturfreie Bearbeitung und erzielt hocheffiziente, hochpräzise Oberflächenqualitäten.

Automationsintegration & Serienfertigung

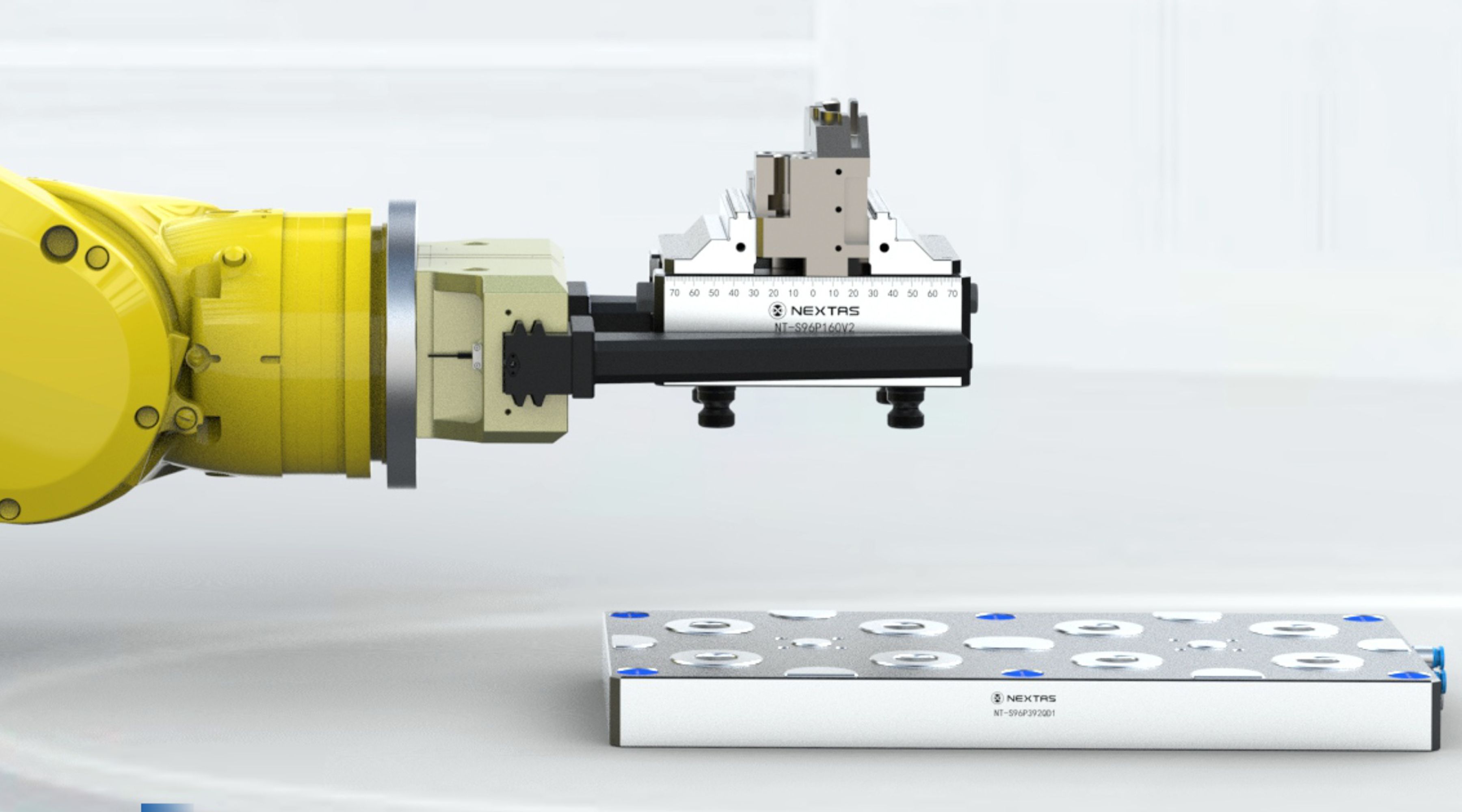

Roboterarm-Integration

Die Greiferschnittstelle an der Seite des Spanners ermöglicht eine nahtlose Integration mit Roboterarmen, was ein automatisiertes Be- und Entladen der Werkstücke für eine 24/7 mannlose Fertigungslinie ermöglicht.

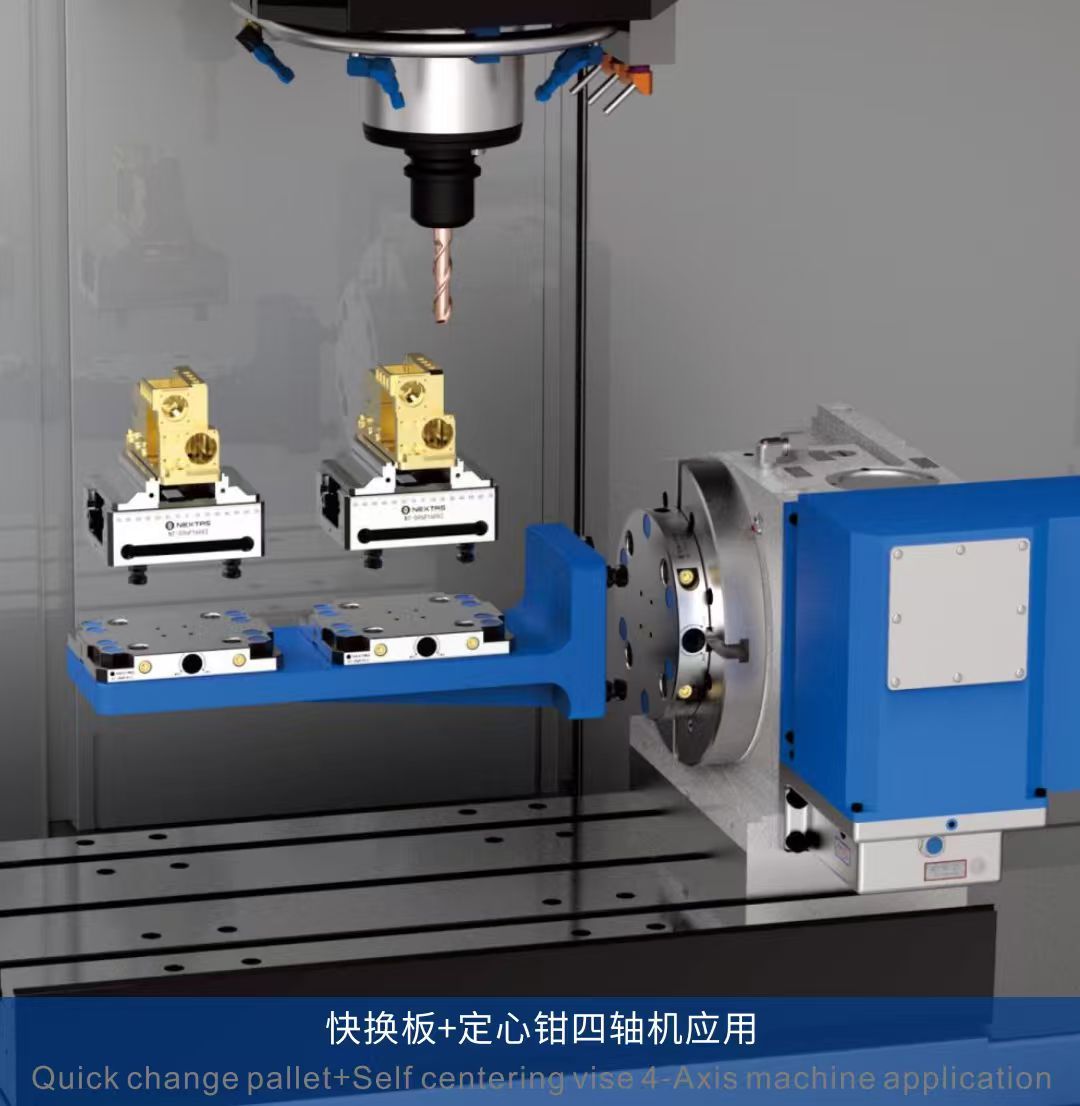

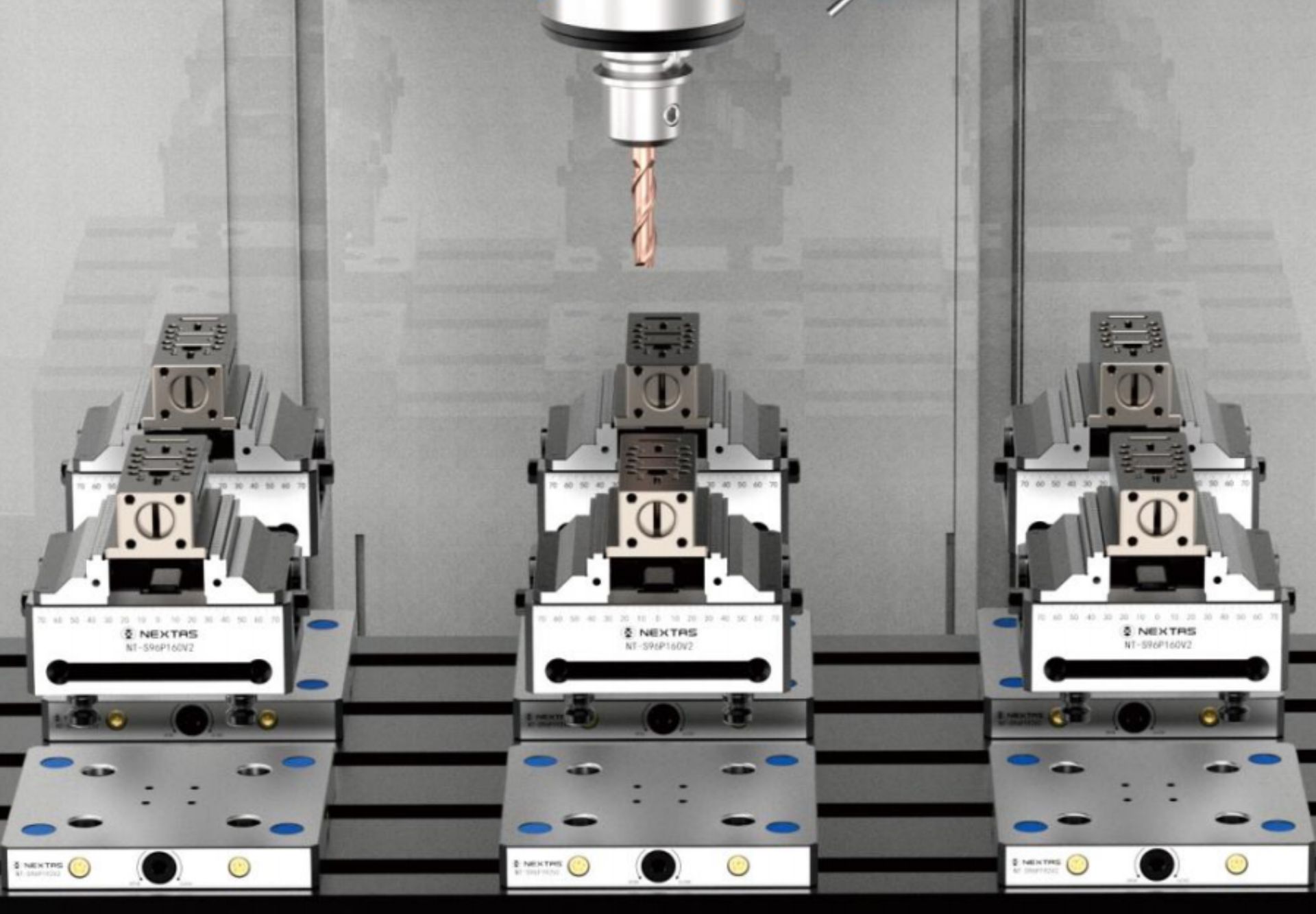

Mehrfachspannung

Die Anordnung mehrerer Spanner auf dem Maschinentisch ermöglicht die Bearbeitung mehrerer Werkstücke in einer Aufspannung, was die Produktionseffizienz erheblich steigert.

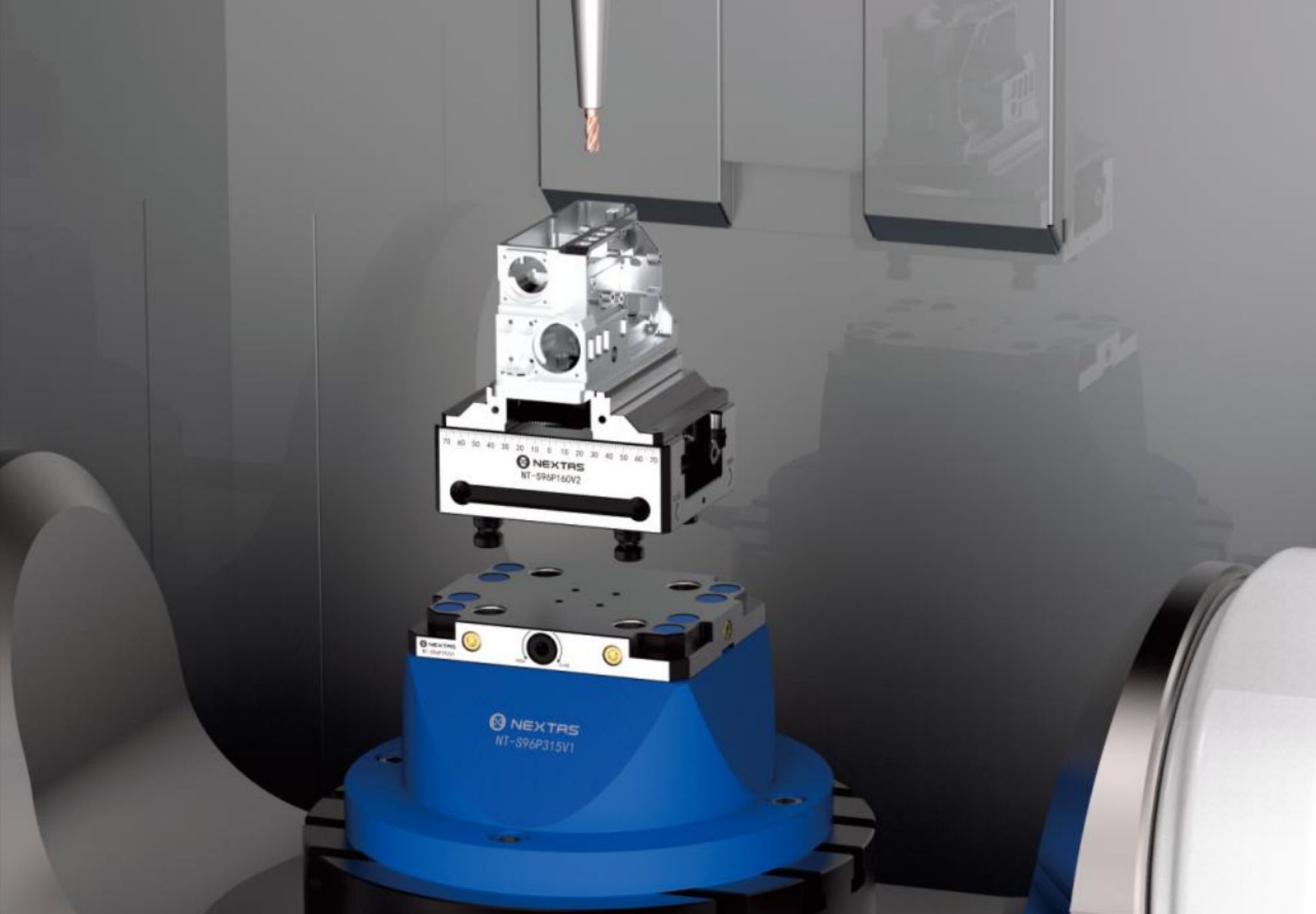

Kombiniert mit Palettenwechselsystemen

Die Montage des Spanners auf einer standardisierten Palette ermöglicht das Offline-Rüsten, was die Maschinenstillstandszeiten drastisch reduziert und die Auslastung erhöht.

Vielseitige Werkstückspannmöglichkeiten

Unregelmäßige Werkstücke

Durch die Verwendung von Spezialbacken können verschiedenste unregelmäßig geformte Werkstücke wie Guss- und Schmiedeteile sicher gespannt werden und bieten eine stabile Bearbeitungsbasis.

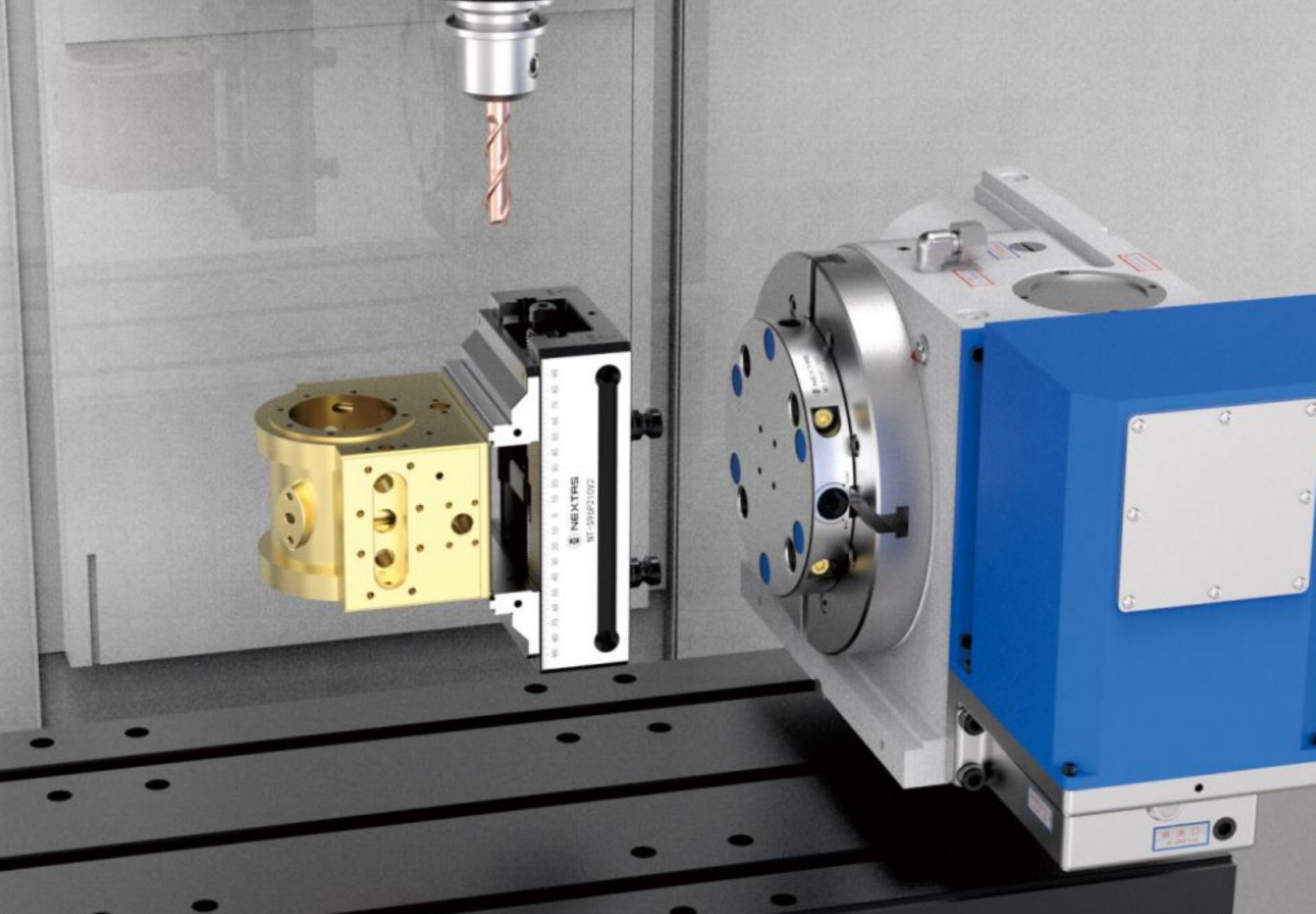

4-Achs-Anwendung

Die leichten und hochsteifen Eigenschaften des Spanners machen ihn auch ideal für die Montage auf einem 4-Achs-Rundtisch zur mehrseitigen Bauteilbearbeitung.

Rundmaterial-Werkstücke

Kombiniert mit Prismenbacken (V-Jaws) lässt sich eine präzise und stabile Zentrierspannung von Rundmaterial einfach erreichen, ideal für die Bearbeitung wellenförmiger Teile.

Fallstudien aus der Praxis

Präzision und Leistung, geliefert an unsere Kunden.

Häufig gestellte Fragen

Ihre Fragen, beantwortet.

Wie geht der Zentriermechanismus mit rauen oder asymmetrischen Werkstücken um?

Welche Wartung wird empfohlen, um die Zentriergenauigkeit von — ,01 mm zu erhalten?

Kann dieser Spanner in ein Nullpunktspannsystem integriert werden und wie erfolgt die Montage?

Sie erwähnten 'Automationsbereit'. Welche spezifischen Funktionen unterstützen dies?

Werde ich beim Spannen eines Werkstücks einen Backenauftrieb (Jaw Lift) erleben?

Verwandte Produkte

Nullpunktspannsystem

Erzielen Sie schnelle Rüstwechsel mit einer Wiederholgenauigkeit von ±0,002 mm und steigern Sie die Produktionseffizienz.

Details ansehen →

E-Series Pneumatikfutter

Vielseitiges und präzises Spannfutter für eine breite Palette von Drehanwendungen.

Details ansehen →

Automatischer Palettenwechsler

Optimieren Sie Ihren Arbeitsablauf mit automatisierten Palettenwechseln für eine kontinuierliche Produktion.

Details ansehen →