Pioneering Precision and Efficiency in Global Manufacturing

Learn how Nextas is driving the future of CNC machining and automation with our advanced quick-change workholding solutions.

Our Journey: 15 Years of Innovation

Founded in March 2009, Nextas embarked on a mission to revolutionize industrial workholding. For over 15 years, we have been at the forefront of designing, developing, and manufacturing high-precision quick-change clamping systems. Our integrated approach combines R&D, state-of-the-art production, and global sales from our 43,600-square-meter facility in Zhuhai, China.

With a dedicated team of over 500 professionals, including a robust R&D department that constitutes 55% of our workforce, we are relentlessly committed to pushing the boundaries of what's possible in precision manufacturing.

Engineered for Excellence: Our Technology

Maximize Efficiency

Our Zero-Point System drastically reduces setup times, boosting your productivity and throughput.

Automate for the Future

Embrace Industry 4.0 with our automation-ready fixtures designed for seamless integration.

The Nextas Advantage

Nextas provides custom CNC workholding solutions engineered to enhance machine tool efficiency. We're committed to delivering high-quality products at competitive prices with rapid turnaround times, rivaling industry leaders like LANG and 5th Axis.

Experience the Nextas difference—precision-engineered solutions that elevate your machining capabilities.

- Exceptional Repeatability: Guarantee positioning accuracy within 0.02mm for consistent results.

- Powerful Clamping Force: Strong and stable holding power of 20Kn, suitable for heavy-duty cutting.

- Internationally Accepted Connector: Universal with 52 and 96 type spigots to improve clamping efficiency.

- Quick Change Jaws: Jaws can be installed frontally or reversely. Custom soft jaws are available.

- Meticulous Design: Side clamping grooves facilitate gripping by manipulators for automation.

Explore Our Facility

Take a virtual walk through our state-of-the-art production facility. See for yourself where innovation and precision come to life.

Trusted by Industries Worldwide

From aerospace to medical devices, our precision systems provide the reliability and performance that leading global industries demand.

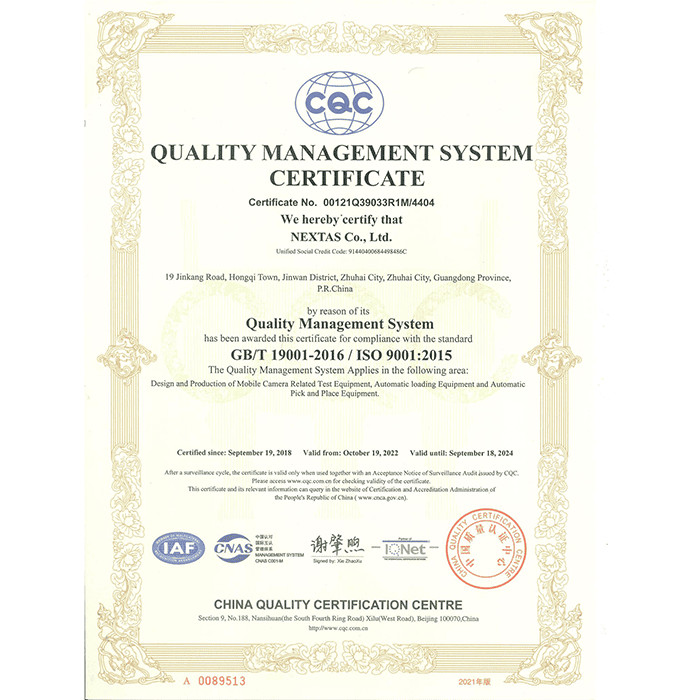

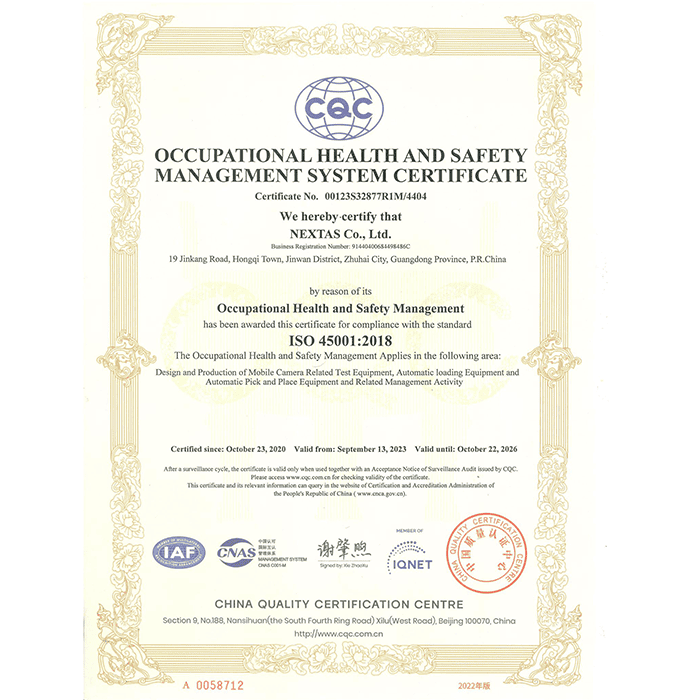

Our Commitment to Unwavering Quality

Our dedication to excellence is validated by internationally recognized certifications, reflecting our systematic approach to quality, safety, and environmental responsibility.

Quality Management

Environmental Management

Occupational Health & Safety

Certificate of Conformity

Our Expertise & Commitment

What is Nextas's primary R&D focus?

Our R&D, which comprises 55% of our workforce, focuses on three key areas: enhancing clamping force and rigidity, developing new materials for extreme wear resistance, and engineering seamless "plug-and-play" automation interfaces for Industry 4.0. This demonstrates our deep technical expertise and commitment to innovation.

How do you ensure quality control as a Chinese manufacturer?

We implement a rigorous multi-stage quality control process to demonstrate our trustworthiness. It starts with raw material verification, includes in-process checks using advanced CMM equipment, and ends with a final 100% inspection of all critical components. Our ISO 9001 certification isn't just a badge; it's our daily operational standard, ensuring you receive products you can trust.

Can we visit your factory in Zhuhai?

Absolutely. We welcome visits from potential clients and partners to showcase our experience and transparency. You can see our advanced production lines, meet our engineering team, and view our quality processes firsthand. Please contact us to arrange a visit or take our 360° virtual tour available on this page.

What is the "Nextas Advantage" compared to other global brands?

The Nextas Advantage is our unique ability to deliver precision and technology rivaling top-tier European and American brands (like LANG or 5th Axis) but with the competitive pricing and rapid, flexible production schedules made possible by our vertically integrated manufacturing base in China. You get world-class innovation without the legacy cost structure—that is our authoritative value proposition.

Ready to Enhance Your Production?

Let's discuss how Nextas can provide a tailored workholding solution to meet your specific needs. Contact our experts today.

Get in Touch