Please enter your email address to receive the product catalog directly in your inbox.

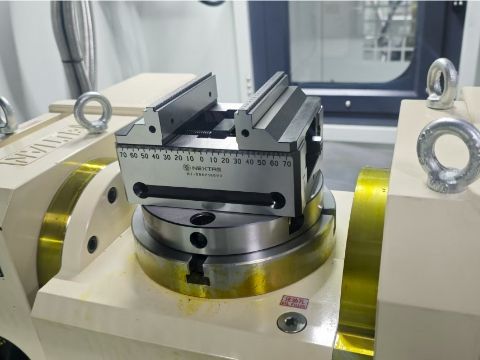

High-Precision 5-Axis Self-Centering Vise

Engineered for 5-Axis & Automation

The Nextas Self-Centering Vise is the ultimate workholding solution for modern 5-axis machining and automated production. Its innovative design provides exceptional clamping rigidity and high repeatability, while the compact form factor minimizes interference, maximizing tool access to the workpiece. It is a cornerstone for any enterprise looking to boost efficiency and precision.

Core Advantages

- High Repeatability: Guarantees a centering accuracy of ≤.01mm and repeat clamping accuracy of ≤.02mm for consistent, high-quality results.

- Powerful & Stable Clamping: Unique mechanism delivers strong, stable holding power (up to 35kN), suitable for heavy-duty cutting.

- Optimized for 5-Axis: Compact, symmetrical design minimizes tool interference, providing maximum accessibility for complex part machining.

- Automation Ready: Features clamping grooves for robotic grippers and is compatible with zero-point systems for rapid, automated changeovers.

In-Depth Product Details

Discover the engineering excellence behind our Self-Centering Vise.

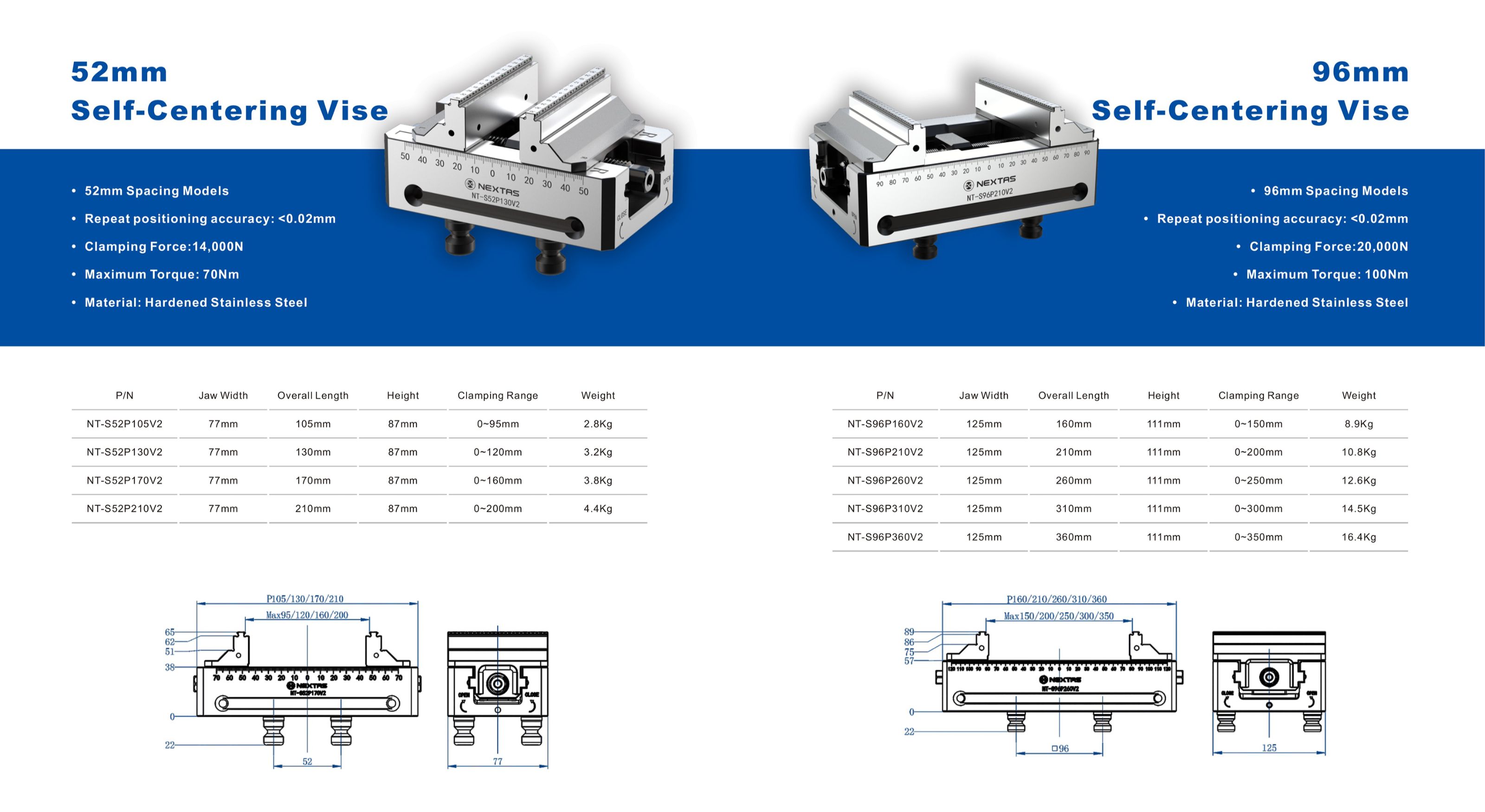

Key Technical Specifications

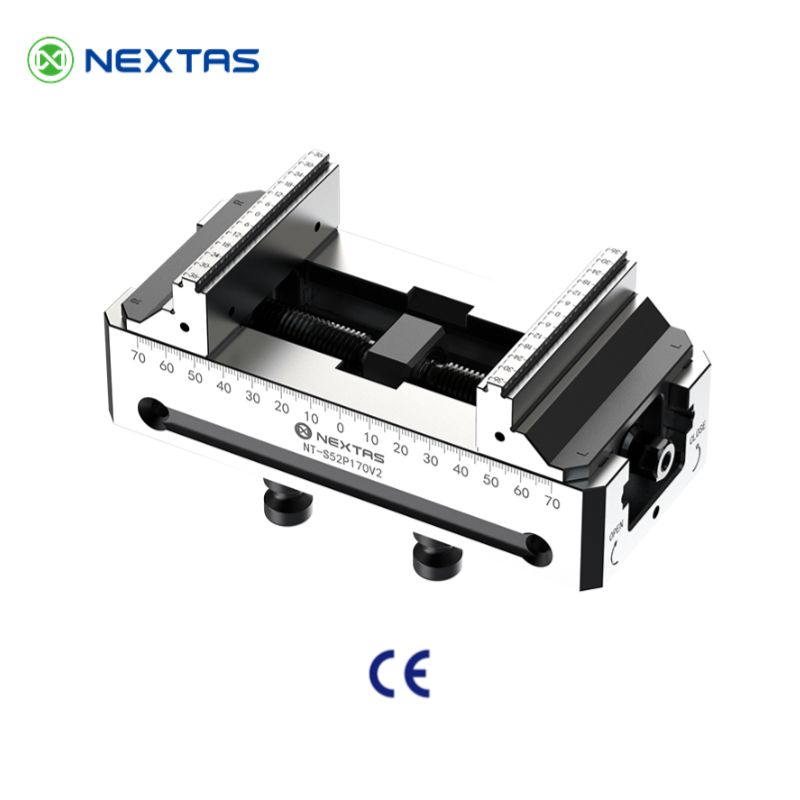

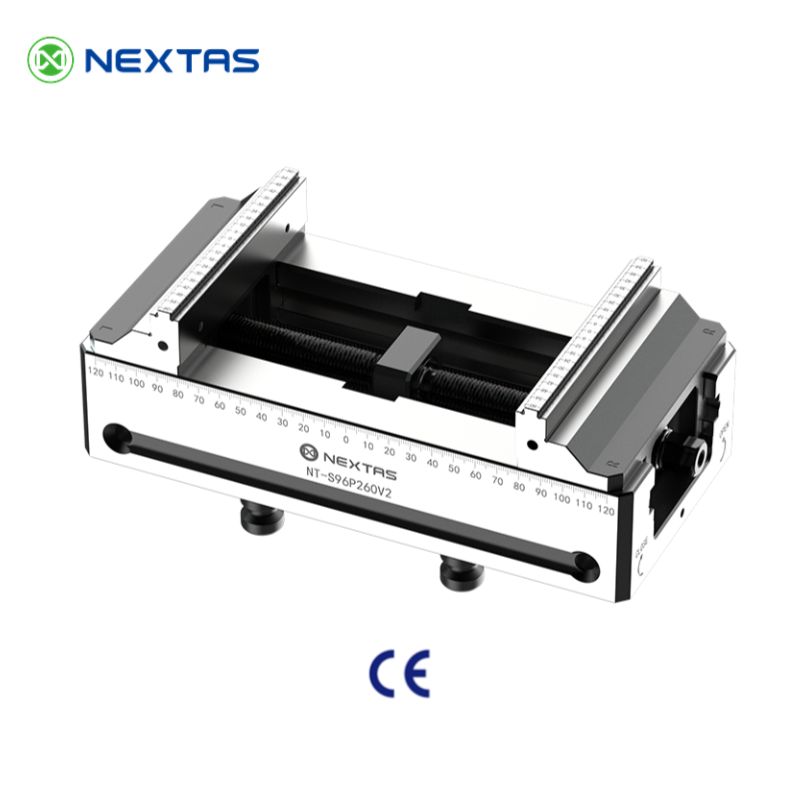

| Parameter | Model: NT-S52P170V2 | Model: NT-S52P210V2 |

|---|---|---|

| Vise Width | 77 mm | 125 mm |

| Max Clamping Range | 0 - 160 mm | 0 - 200 mm |

| Max Clamping Force | 14 kN | 20 kN |

| Repeatability | ±0.02 mm | ±0.02 mm |

| Body Material | High‑Strength Tool Steel (HRC 50±5) | High‑Strength Tool Steel (HRC 50±5) |

| Actuation | Manual (Torque Wrench) | Manual (Torque Wrench) |

| Weight | 3.8 kg | 10.8 kg |

Jaw Specifications & Clamping Range

| Jaw Type | Clamping Range (NT‑S52P170V2) | Clamping Range (NT‑S52P210V2) |

|---|---|---|

| Standard Jaws | 10 - 170 mm | 20 - 210 mm |

| Serrated Jaws | 20 - 180 mm | 30 - 220 mm |

| V‑Jaws | Ø 10 - 100 mm | Ø 20 - 150 mm |

Engineered for Precision and Efficiency

The Nextas self-centering vise is a cornerstone of modern CNC machining. We use high-strength alloy steel, precision-ground and heat-treated, to ensure maximum rigidity and durability. Its core self-centering mechanism, driven by a high-precision lead screw, guarantees that the workpiece remains perfectly centered during clamping, which is critical for parts requiring high-precision symmetrical machining.

Modularity and Flexibility

Our vise system supports a wide range of standard and custom jaws, providing the optimal clamping solution for everything from raw castings to finished parts. The quick-change jaw design allows you to reconfigure your setup in minutes, drastically reducing setup time and increasing machine uptime.

Rock-Solid Stability

The vise base is designed for seamless compatibility with our zero-point clamping systems, enabling fast and precise mounting. Once installed, the vise forms a rigid unit with the machine table, effectively dampening vibrations even under high-speed, high-feed cutting conditions to ensure superior surface finish and dimensional accuracy.

Enhanced Accessibility

The compact and streamlined design provides maximum accessibility to the workpiece, especially in complex 5-axis machining operations. This allows for shorter tool lengths, reducing vibration and improving cutting performance.

Technical Diagrams

Detailed drawings and specifications for integration.

Application Cases & Solutions

See our vise in action across various industries and setups.

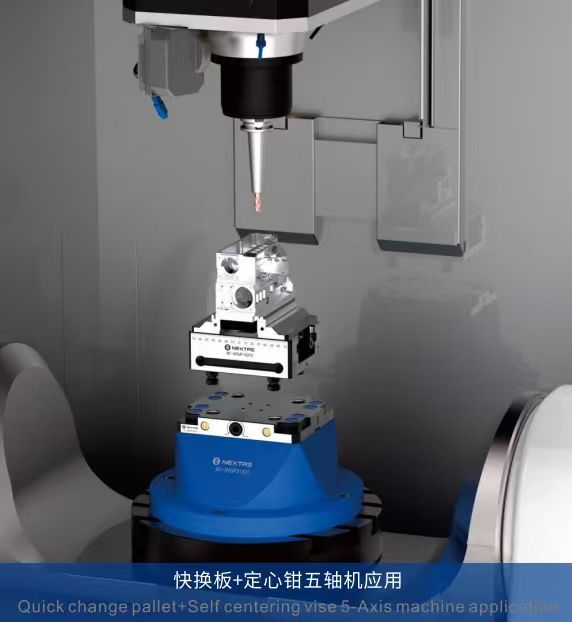

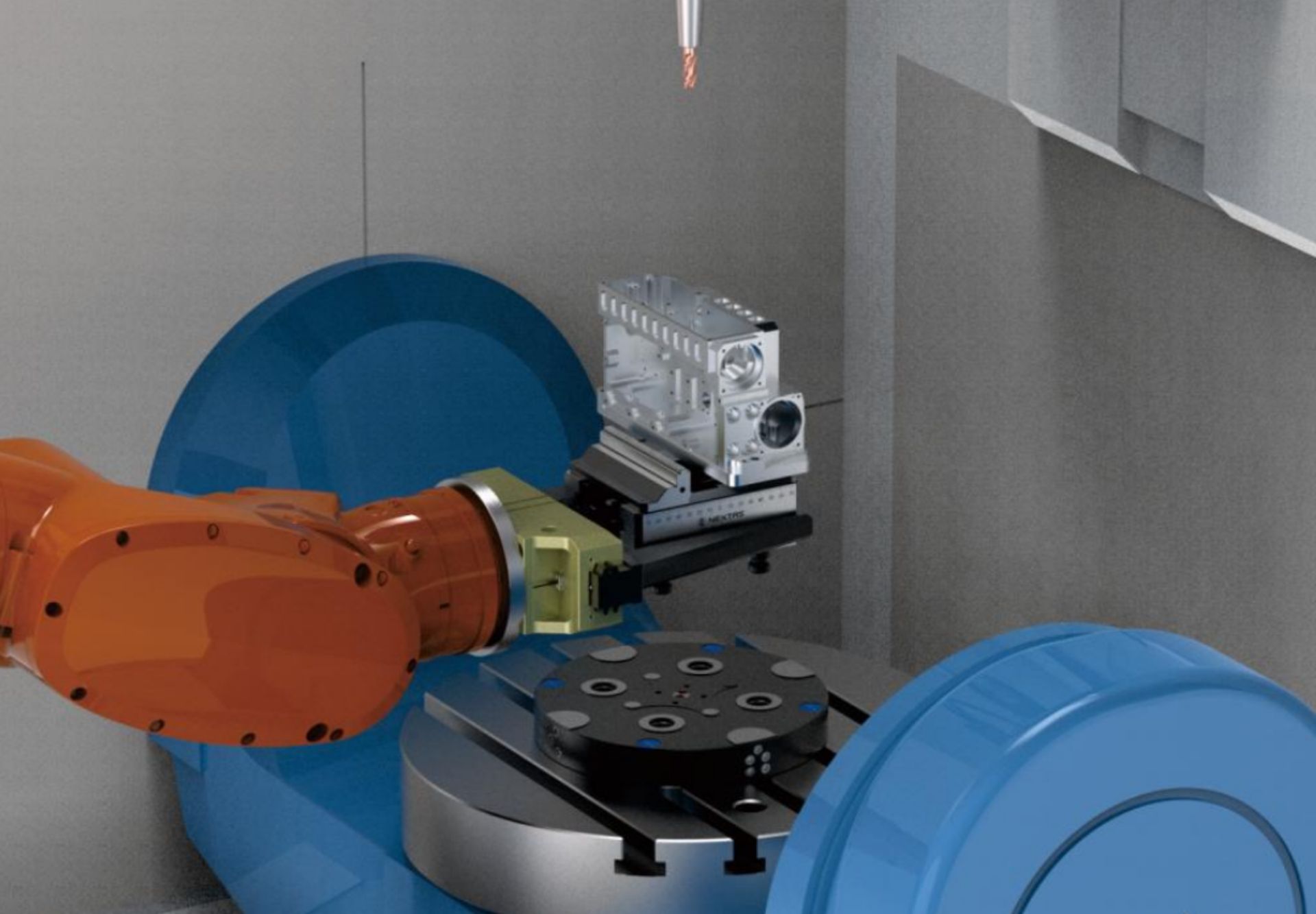

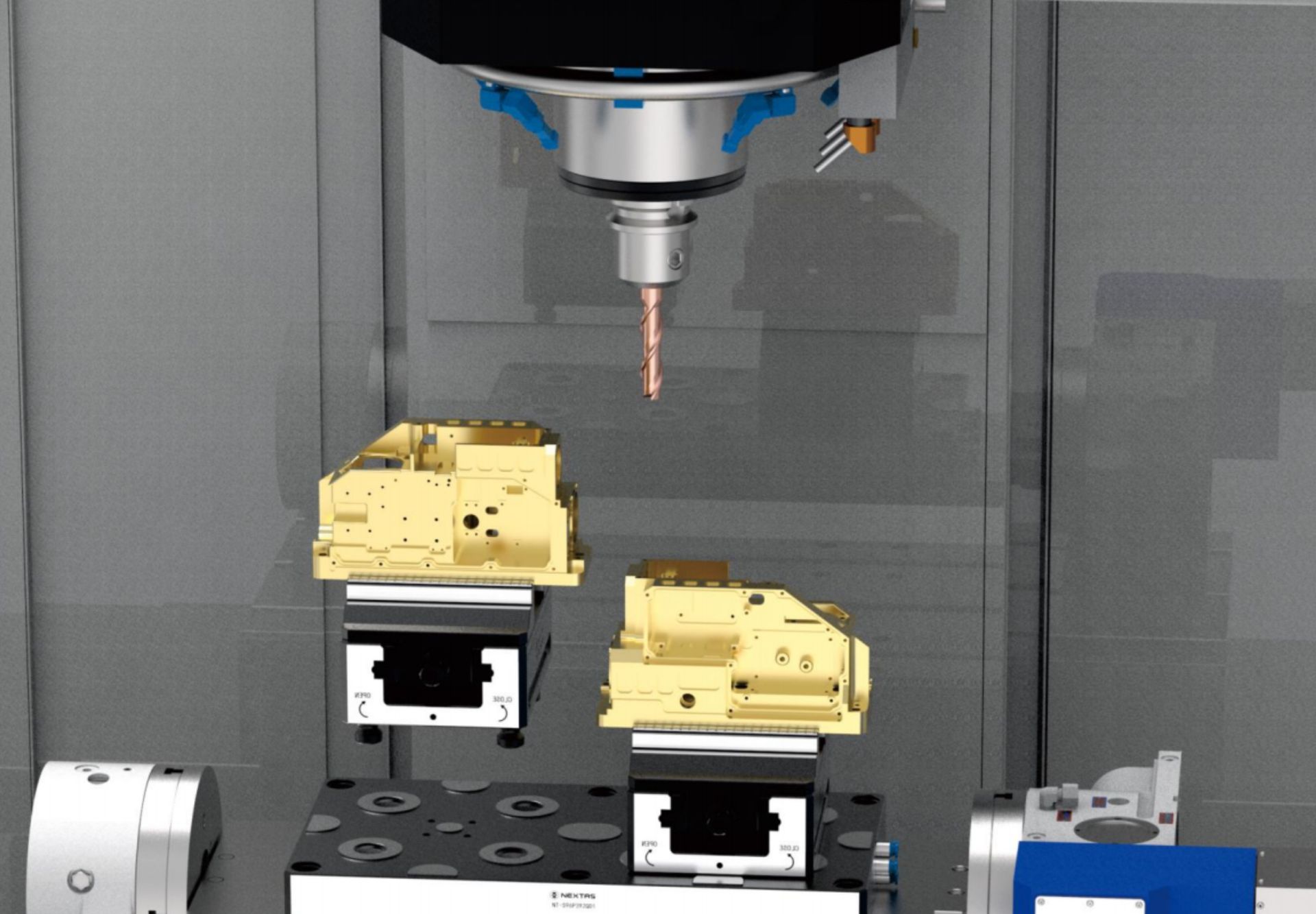

5-Axis Linkage & Complex Surface Machining

The compact design of the Nextas self-centering vise provides excellent tool accessibility for 5-axis machining. Whether for impellers, molds, or complex structural parts, it ensures interference-free processing, achieving high-efficiency, high-precision surface machining.

Automation Integration & Mass Production

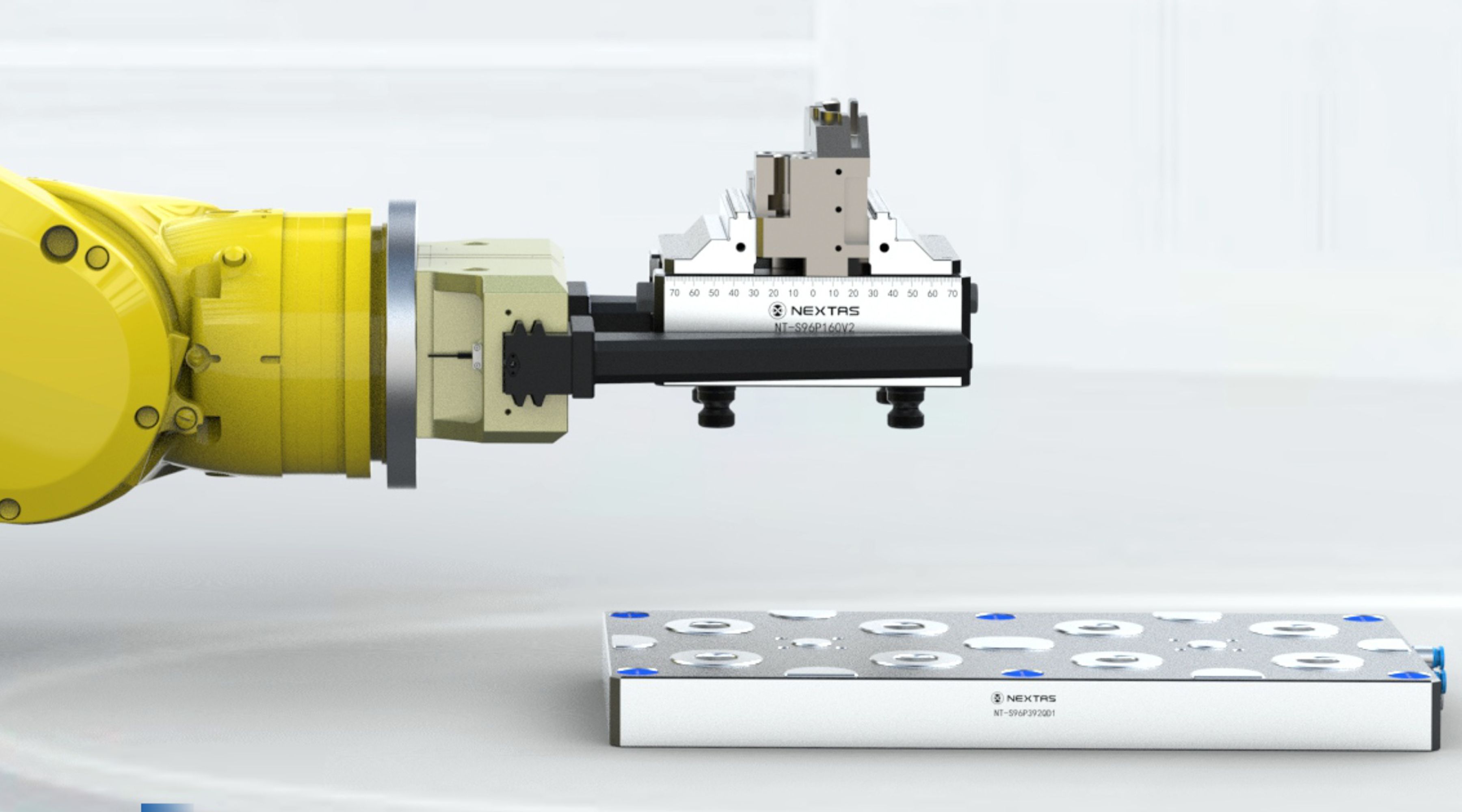

Robotic Arm Integration

The gripping interface on the side of the vise allows for seamless integration with robotic arms, enabling automated workpiece loading and unloading for a 24/7 unmanned production line.

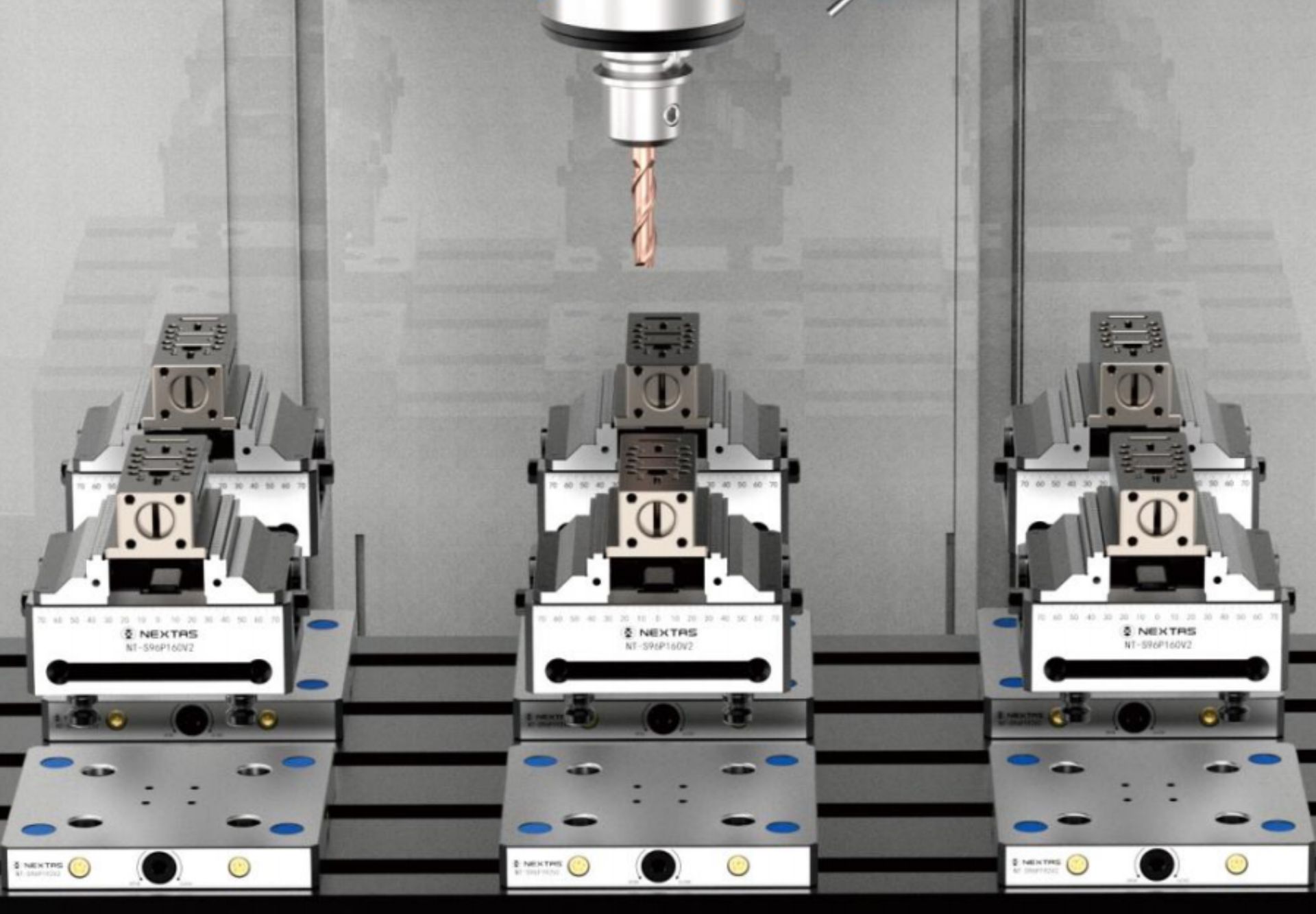

Multi-Vise Array

Arranging multiple vises on the machining center's worktable allows for the processing of multiple workpieces in a single setup, significantly boosting production efficiency.

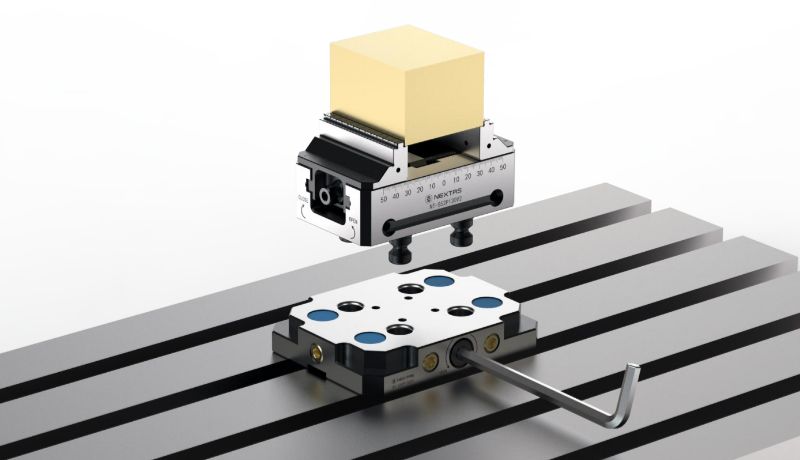

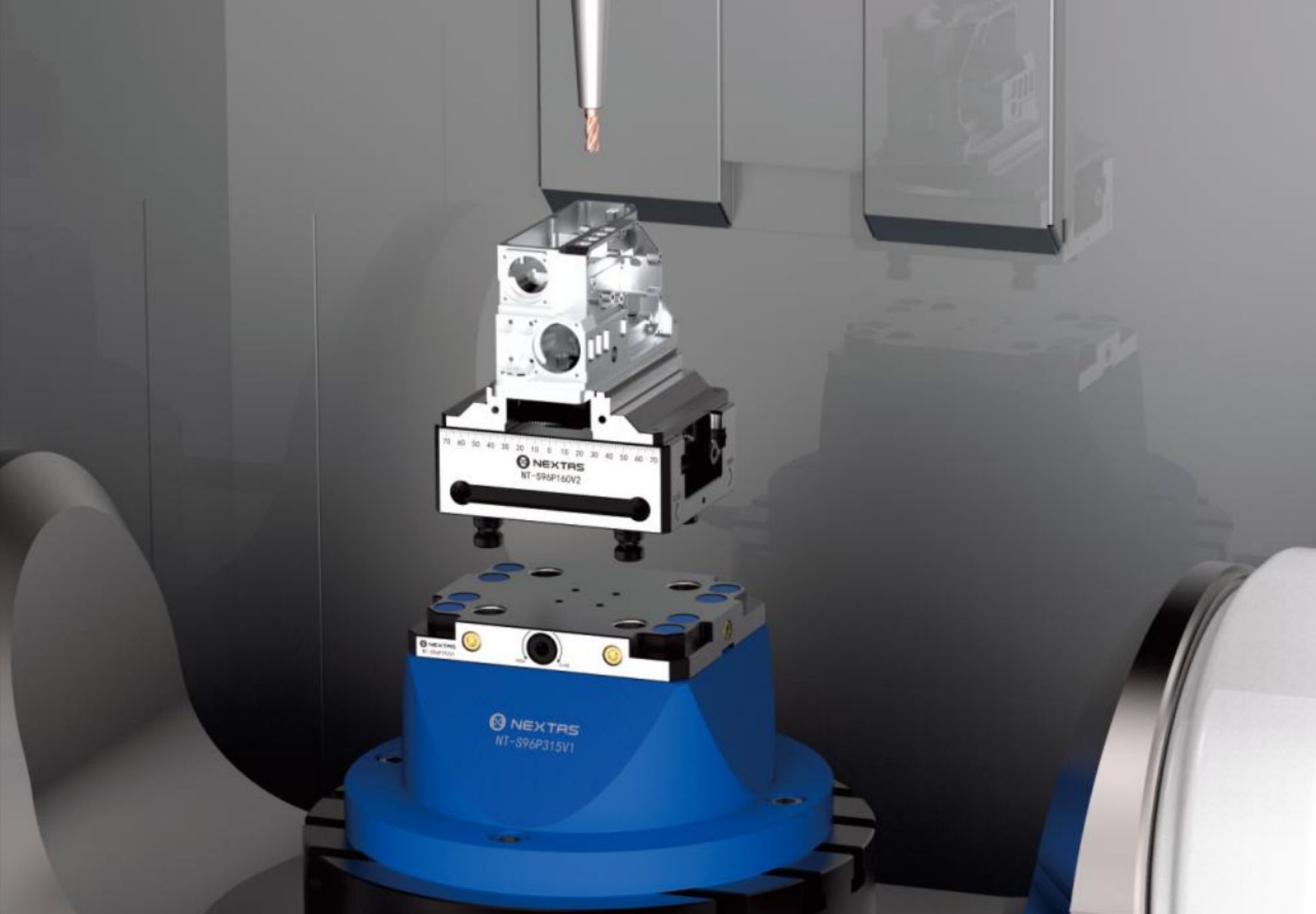

Paired with Pallet Changer Systems

Mounting the vise on a standardized pallet allows for offline pre-setup, drastically reducing machine downtime and increasing equipment utilization.

Versatile Workpiece Clamping Capabilities

Irregular Workpieces

By using special jaws, it can securely clamp various irregularly shaped workpieces such as castings and forgings, providing a stable machining base.

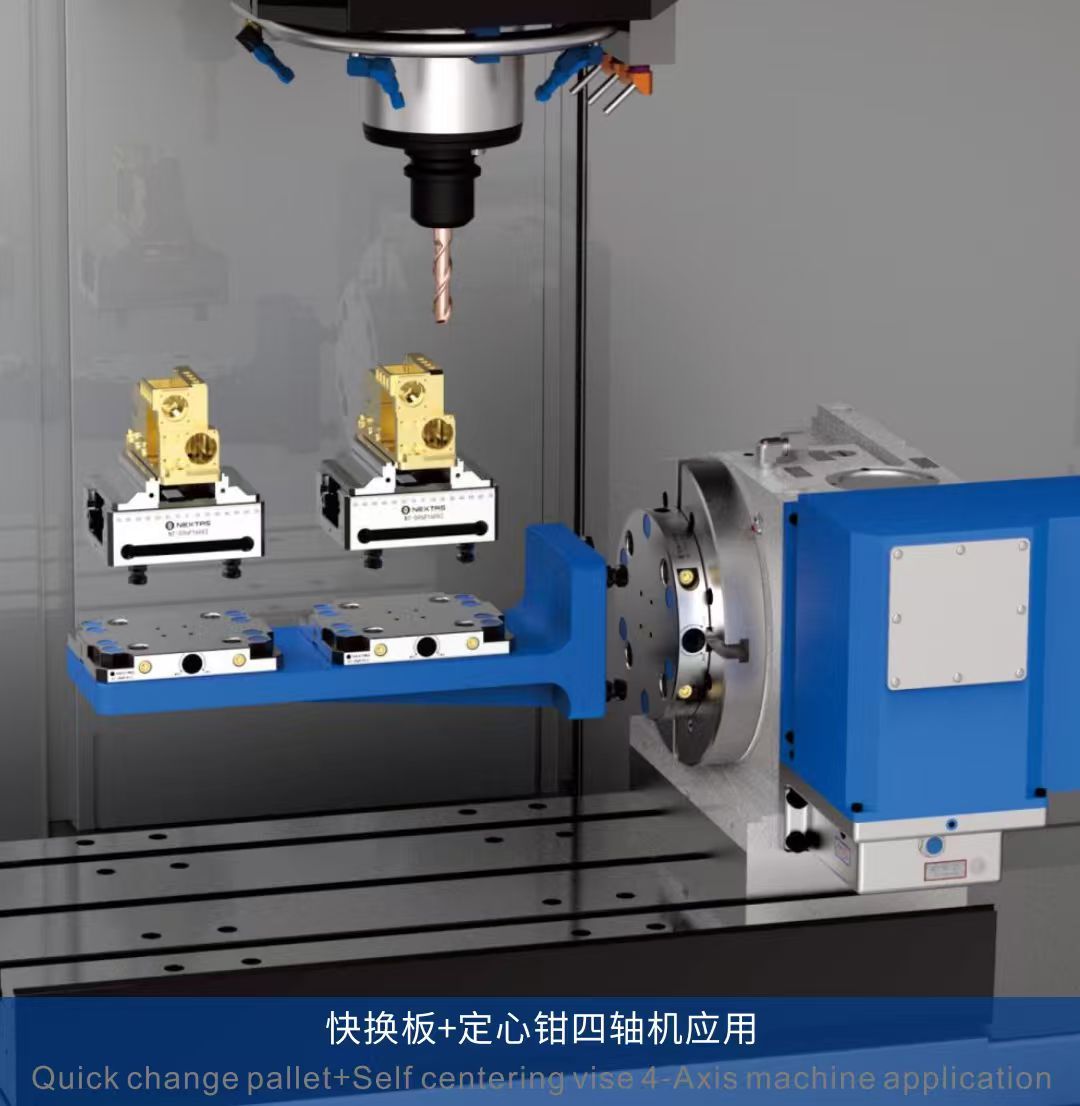

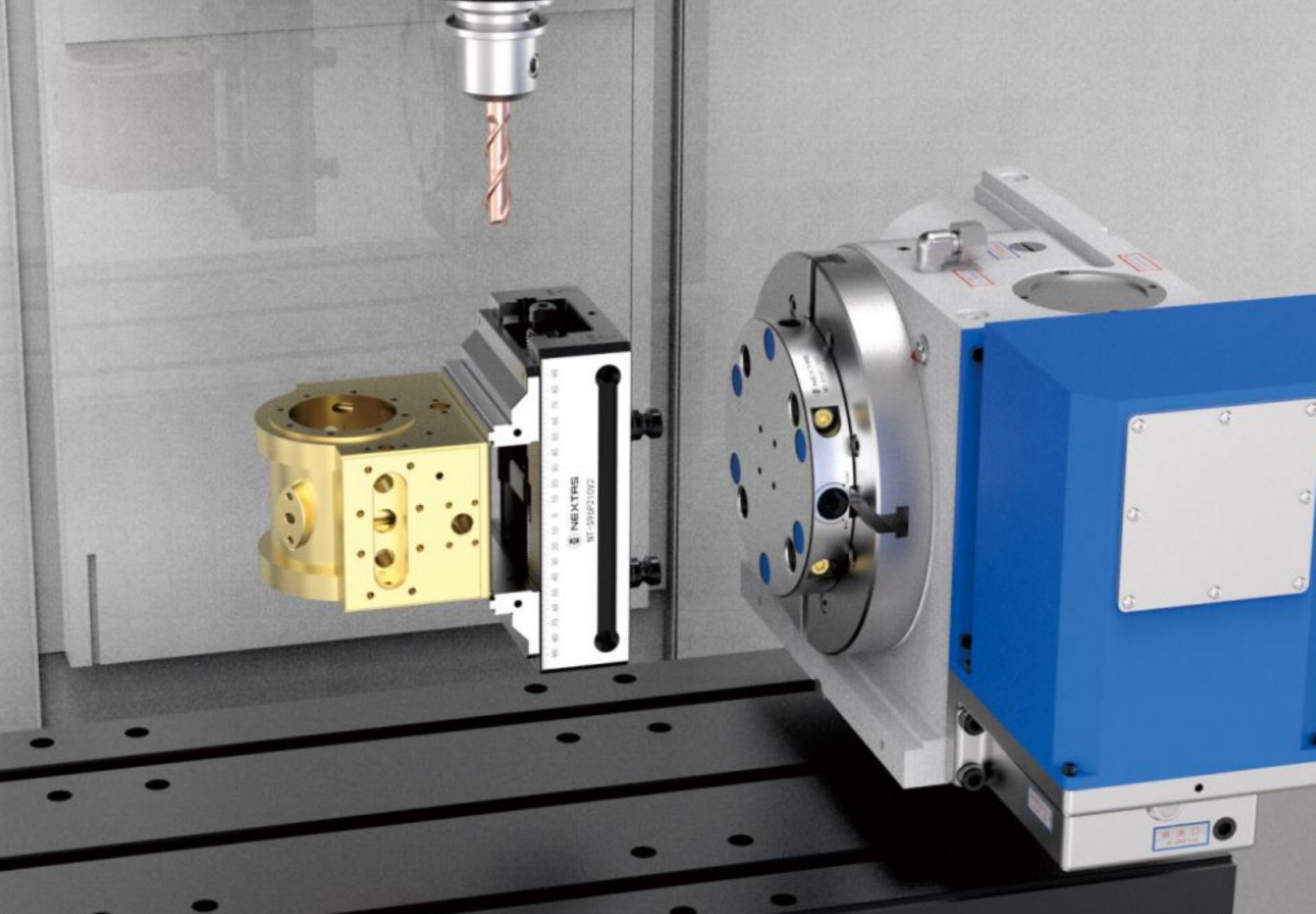

4th-Axis Application

The vise's lightweight and high-rigidity features also make it suitable for mounting on a 4th-axis rotary table for multi-sided component machining.

Round Bar Workpieces

Paired with V-jaws, it can easily achieve precise and stable center clamping of round bar workpieces, suitable for machining shaft-like parts.

Real-World Case Studies

Precision and performance delivered to our clients.

Frequently Asked Questions

Your questions, answered.

How does the self-centering mechanism handle rough or asymmetrical workpieces?

What is the recommended maintenance for maintaining the ≤.01mm centering accuracy?

Can this vise be integrated with a zero-point clamping system, and how does it mount?

You mentioned 'Automation Ready'. What specific features support this?

Will I experience jaw lift when clamping a workpiece?

Resources & Downloads

Related Products

Zero Point Clamping System

Achieve rapid changeovers with ±0.002mm repeatability, boosting production efficiency.

View Details →>

E-Series Chuck

Versatile and precise chuck for a wide range of turning applications.

View Details →>

Automatic Pallet Changer

Streamline your workflow with automated pallet changes for continuous production.

View Details →>