How to Perfectly Use a High-Precision Pneumatic Vise to Achieve Machining Upgrades

A comprehensive guide to optimizing CNC machining with high-precision pneumatic vises, covering application scenarios, automation, and maintenance.

Insights, use-case stories, and machining tips to boost your productivity.

A comprehensive guide to optimizing CNC machining with high-precision pneumatic vises, covering application scenarios, automation, and maintenance.

Redefine rapid mold changes with the NEXTAS Self-Centering Vise. Featuring zero-point compatibility, ±0.002mm repeatability, and 35kN clamping force.

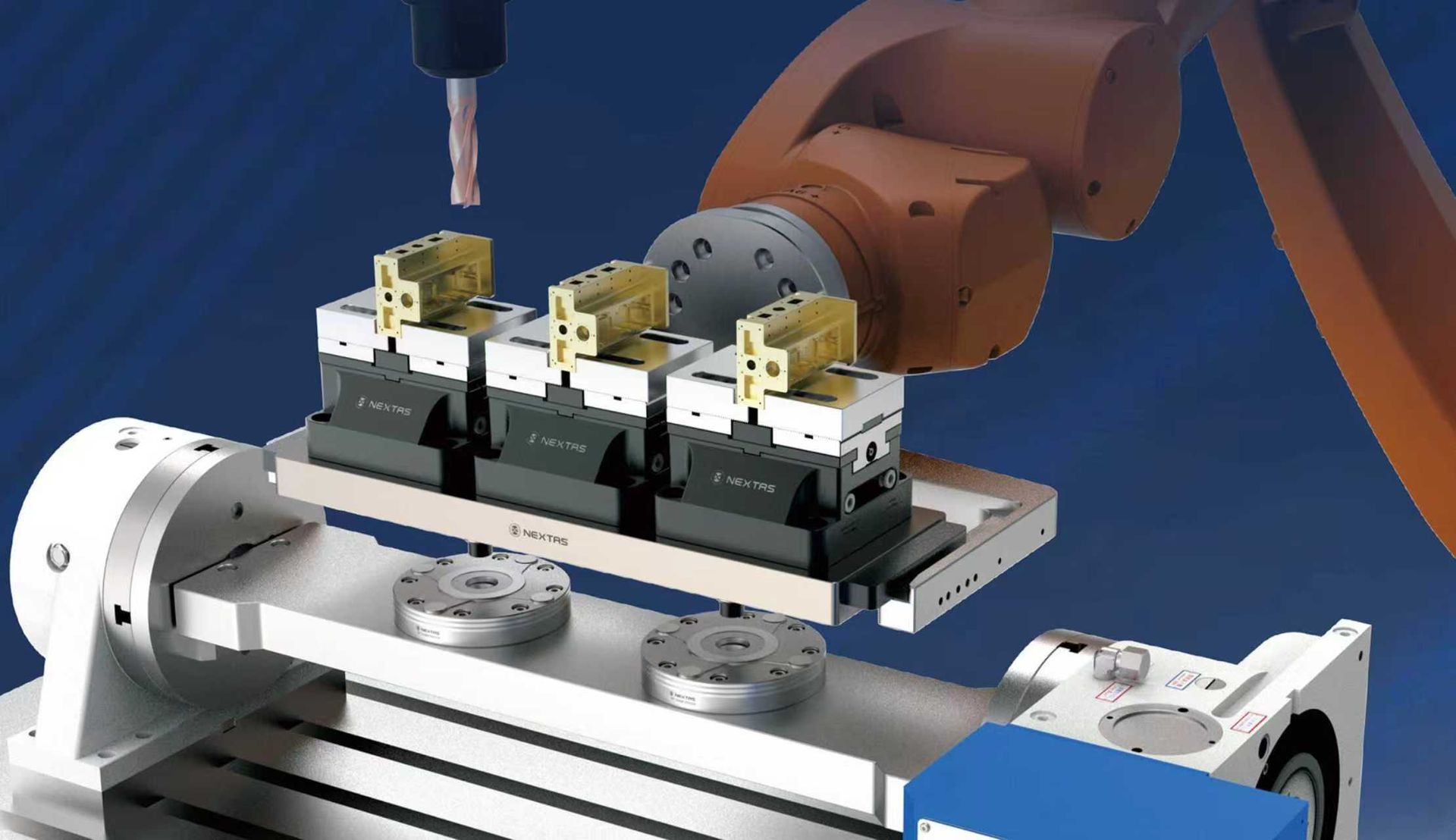

Discover Nextas FMS, a fully integrated Flexible Manufacturing System. Learn how our proprietary software, zero-point clamping, and turnkey implementation reduce downtime and boost productivity.

Nextas Custom-Made Pneumatic Fixtures are engineered for your specific workpiece. Featuring 25,000N clamping force, ±0.002mm accuracy, and automation compatibility.

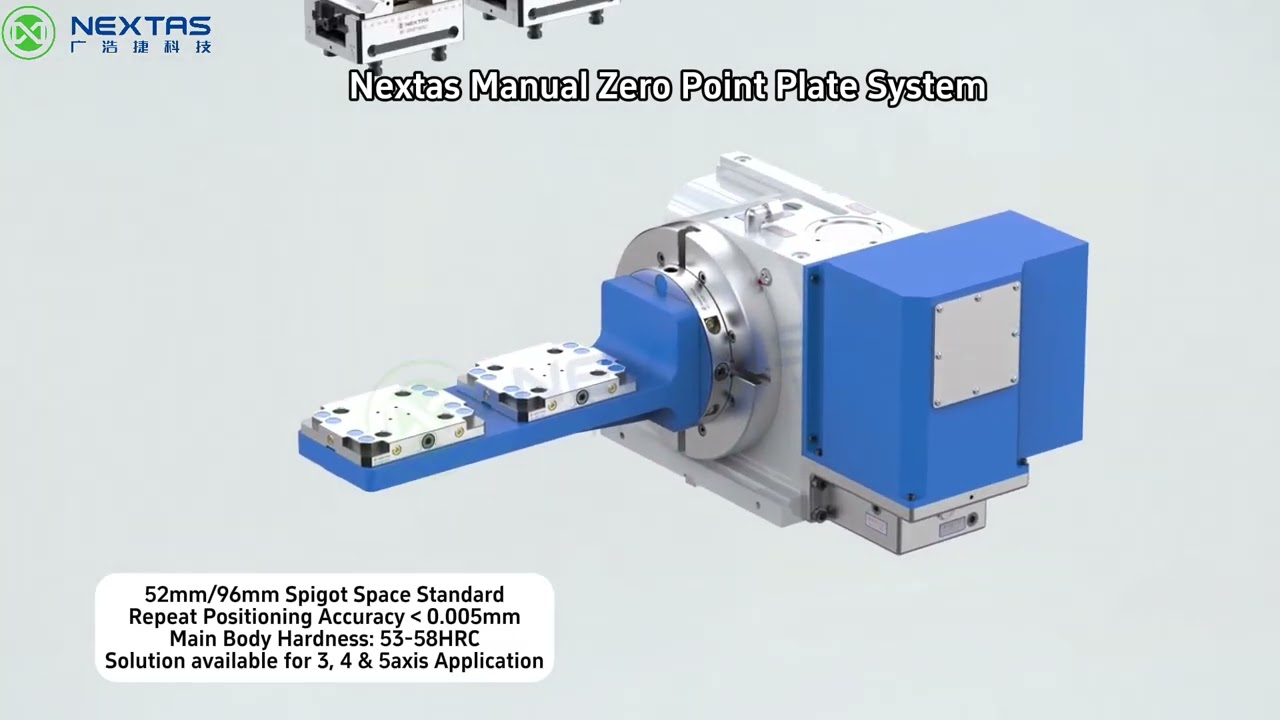

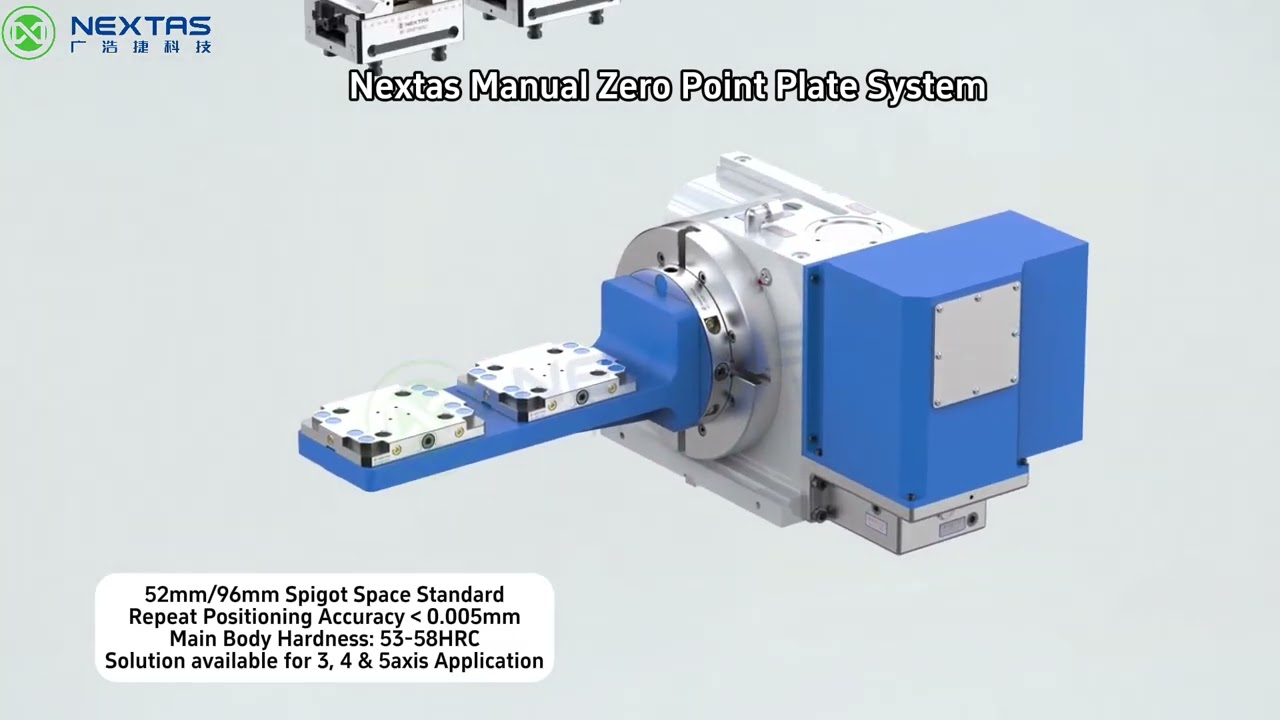

Reduce setup time by 90% with unrivaled modularity, ≤.005mm accuracy, and rock-solid durability. Discover why elite machinists choose Nextas.

Discover how Nextas's affordable, scalable FMS solutions, featuring proprietary high-precision fixtures (±0.005mm), empower Small-to-Medium Manufacturers (SMMs) to boost productivity, reduce scrap rates, and scale production.

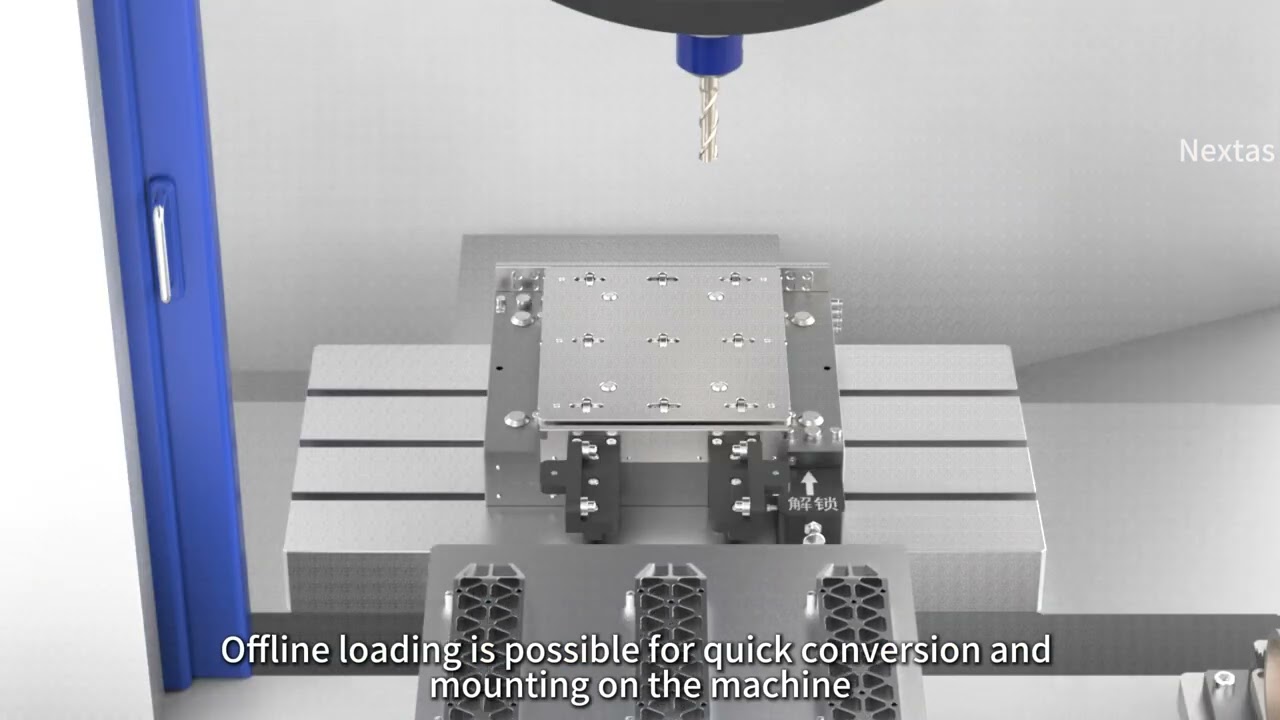

Discover how a Manual Pallet Changer System can boost your CNC efficiency by over 70%. Learn how it eliminates downtime through simultaneous operations. Read the Zhibo Technology case study.

Discover how the ≤.01mm repeatability pneumatic vise transforms CNC machining, boosting precision, reducing scrap, and enabling automation.

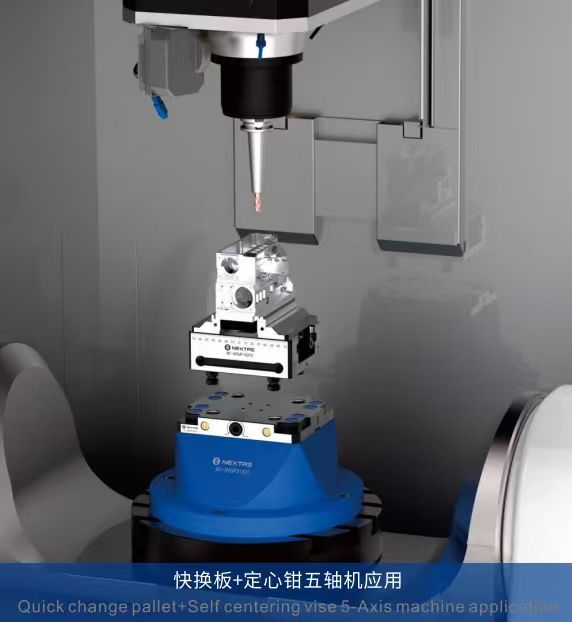

Discover how 5-axis self-centering vises from Nextas, featuring quick-change jaws and multi-station designs, dramatically improve CNC machining efficiency, precision, and throughput for complex workpieces.

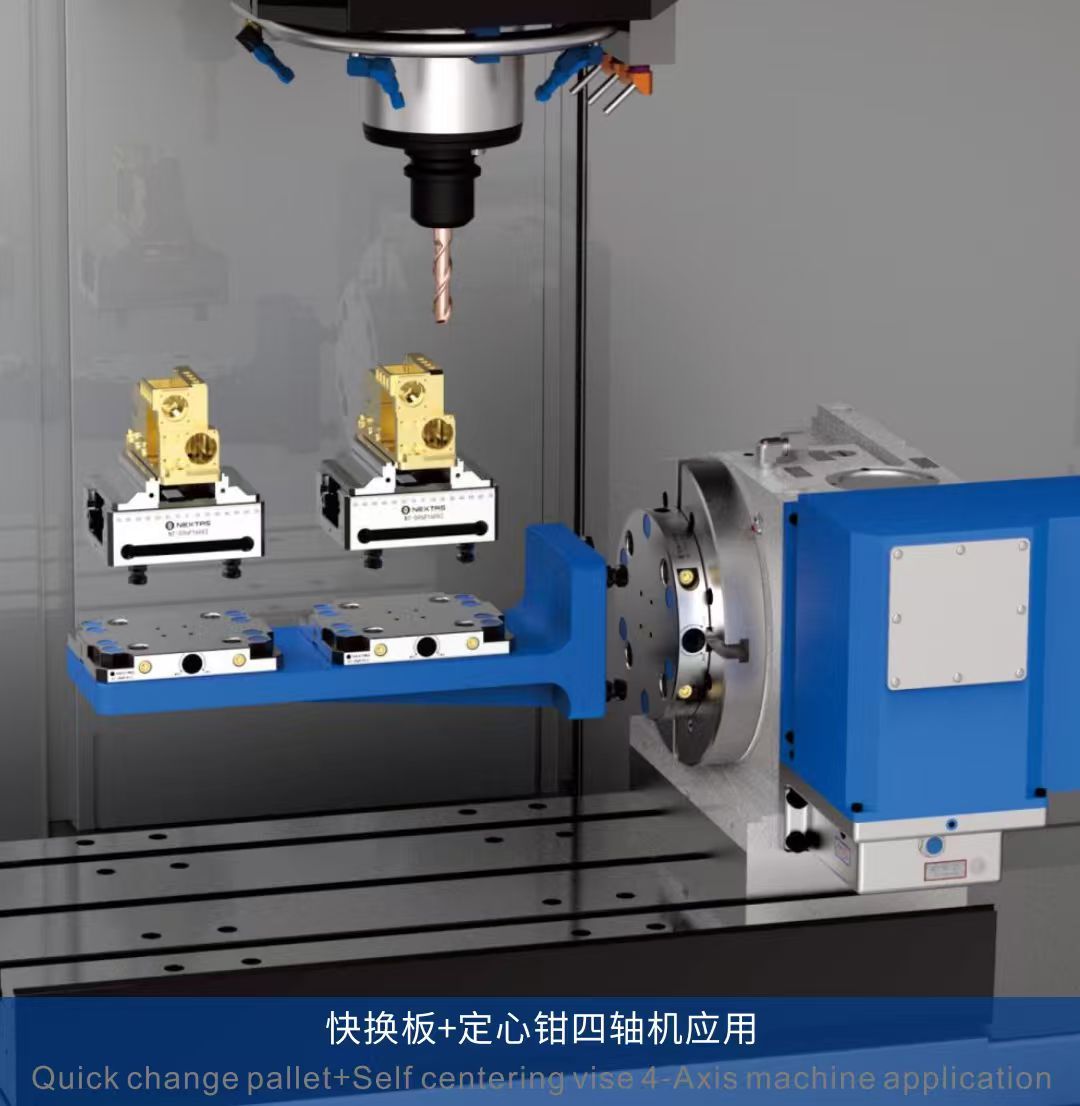

Discover how the quick-change jaws and multi-station design of Nextas self-centering vises dramatically reduce setup times, boost throughput, and enhance precision in CNC machining.

Discover how the NEXTAS automated integration solution helped Lang'an Precision increase production efficiency by over 30%, setting a new benchmark for unmanned workshop transformations.

Solve large‑part machining with the Nextas Side‑Inlet Zero‑Point system: <0.003 mm repeatability, >40,000 N clamping, up to 90% faster changeovers.

Why modern automotive plants choose hydraulic fixture systems: higher clamping force, micron‑level accuracy, faster changeovers, and measurable ROI.

Discover how Nextas?high‑precision pneumatic vises deliver stable clamping, CNC‑controlled operation and robot compatibility to enable lights‑out manufacturing with zero downtime.

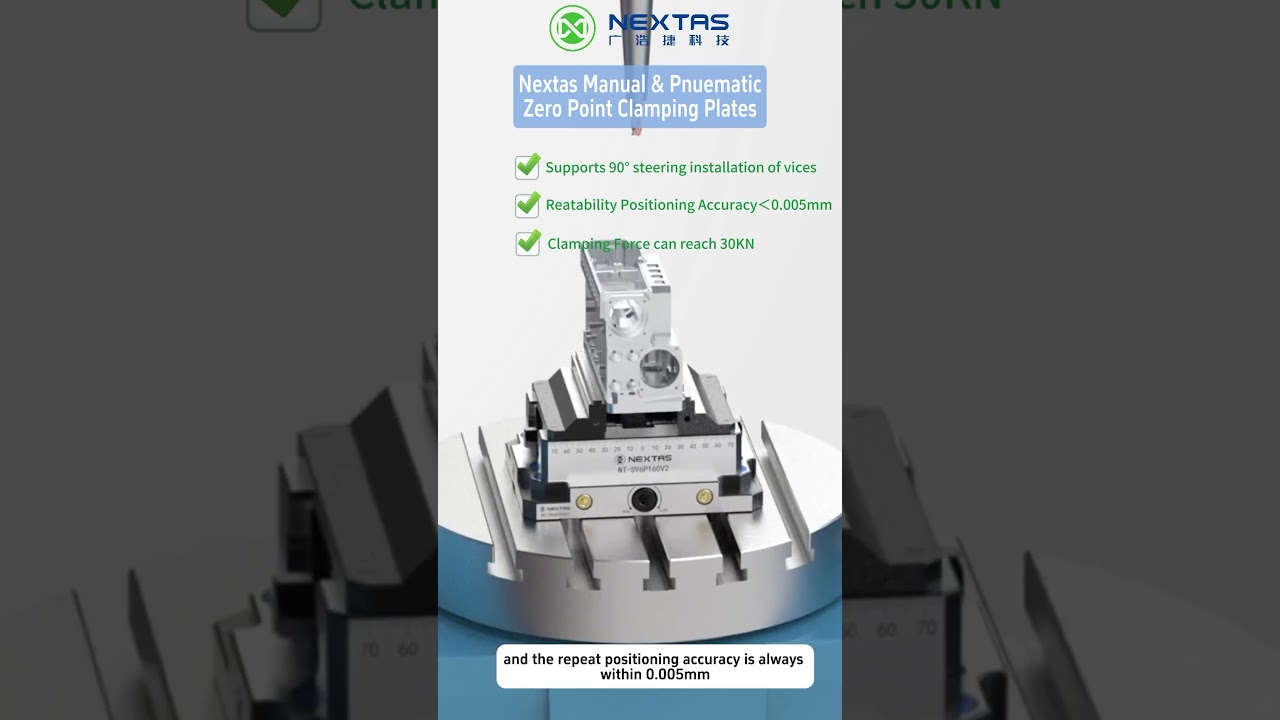

Learn how Nextas?patented Pneumatic Zero‑Point Plates enable lightning‑fast quick changes, 40 kN clamping force and ≤.005 mm accuracy to achieve 24/7 lights‑out manufacturing and a 200% efficiency boost.

Learn what sets 5‑axis self‑centering vises apart for complex machining. Explore symmetric clamping, low‑profile design and how they eliminate secondary setups to boost precision and productivity.

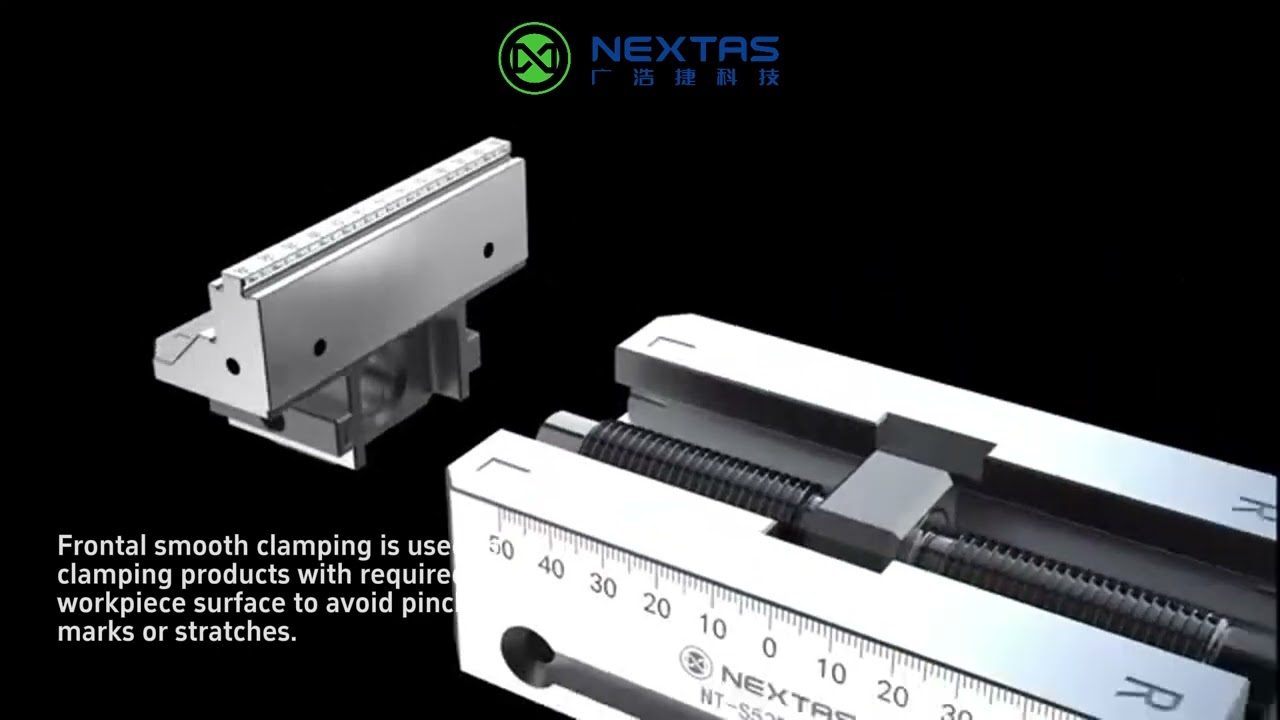

Discover how our high-performance zero-point clamping plates significantly boost your machining efficiency and product quality with repeat positioning accuracy of less than 0.005mm.

Learn how the 55-58 HRC hardness and scientific material matching of our zero-point plates ensure unmatched durability and long-lasting precision.

Discover how the Nextas Self-Centering Vise, combined with our Zero-Point System, boosts CNC throughput and slashes changeover time by 90%.

Learn how the Nextas Self-Centering Vise, with its ≤.02mm repeat positioning accuracy and hardened steel, solves common precision issues.

Since 2009, Nextas has been a leading workholding fixtures manufacturer. Discover our advanced manufacturing, R&D, and comprehensive solutions.

We strive to publish new, in-depth articles, case studies, and technical guides every 1-2 weeks. Our goal is to provide timely and relevant insights to help you stay ahead in the manufacturing industry.

Absolutely! We love hearing from our readers. If you have a specific challenge, question, or topic you'd like us to cover, please send your suggestion to our team via the contact page.

Our workholding solutions are designed for broad compatibility with major CNC machine brands (like Haas, DMG Mori, Okuma, etc.). For specific integration questions about your machine model, we recommend reading the article and then contacting our technical experts for a free consultation.

The best way is to bookmark our blog and check back regularly. You can also follow our company page on LinkedIn, where we share all our new content, updates, and industry news.