Please enter your email address to receive the product catalog directly in your inbox.

Zero-Point Clamping Systems

The Engine of Quick-Change Efficiency

The Nextas Zero-Point Clamping System is the high-performance engine behind modern workholding. These precision-engineered modules provide the powerful clamping force and flawless repeatability needed to slash setup times from hours to seconds, forming the core of any effective quick-change or automated manufacturing strategy.

Module Core Features

- Micron-Level Repeatability: Guarantees a repeat positioning accuracy of ≤0.003mm, ensuring consistent quality.

- Fail-Safe Mechanical Locking: Clamps with powerful spring force, ensuring workpieces stay locked even if air pressure is lost.

- Immense Clamping Force: Provides exceptional rigidity to withstand the most demanding cutting operations without vibration.

- Automation-Ready: Designed for seamless integration with robotics, featuring ports for control, cleaning, and status detection.

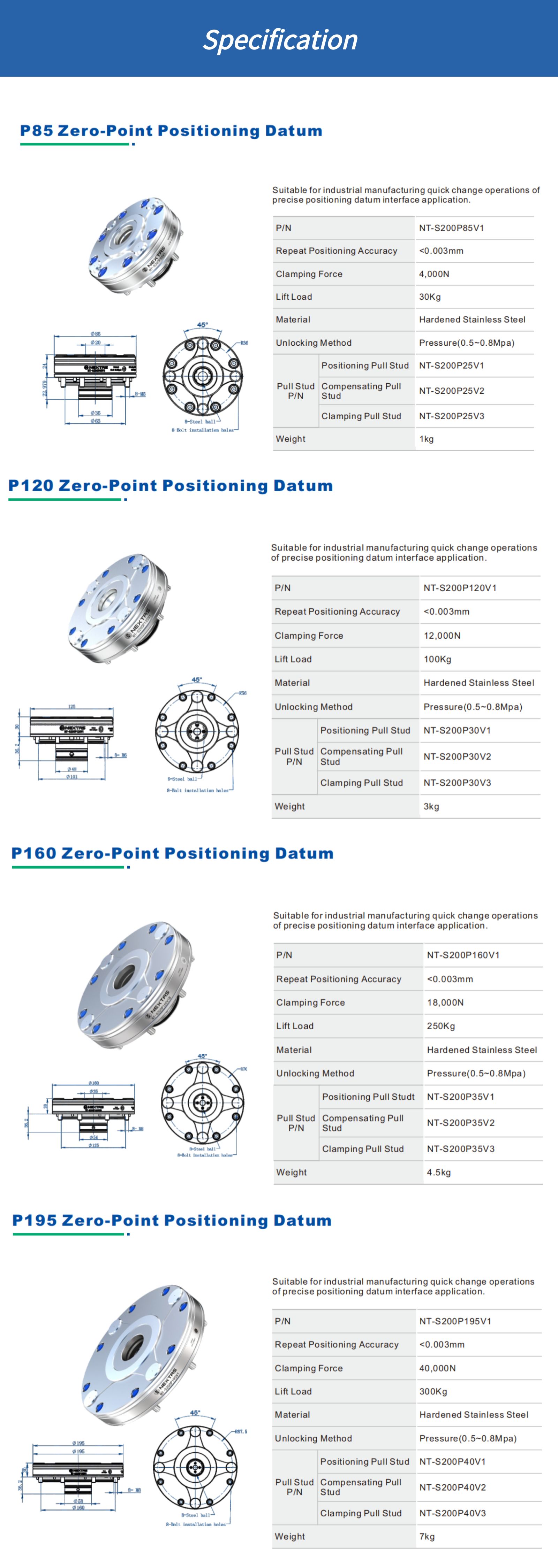

Technical Specifications

| Model | Module Diameter | Clamping Force | Lift Load | Repeatability |

|---|---|---|---|---|

| NT-S200P85V1 | 85 mm | 4 kN | 30 KG | ≤0.003 mm |

| NT-S200P120V1 | 120 mm | 12 kN | 100 KG | ≤0.003 mm |

| NT-S200P160V1 | 160 mm | 18 kN | 250 KG | ≤0.003 mm |

| NT-S200P195V1 | 195 mm | 40 kN | 300 KG | ≤0.003 mm |

Common Specifications (All Models)

- Actuation:Pneumatic Unlocking (6 bar)

- Body Material:Hardened Stainless Steel, Corrosion-Resistant

Mechanism Details

Engineered for Unfailing Performance

Nextas Zero-Point modules are the foundation of modern manufacturing efficiency. Each module is crafted from high-grade, hardened alloy steel for maximum rigidity and service life. The ingenious internal mechanism uses pneumatic pressure (typically 6 bar) to overcome powerful springs for unlocking. When the air is removed, these springs instantly and forcefully pull in and lock the clamping stud, creating a positive, vibration-proof connection that is completely secure.

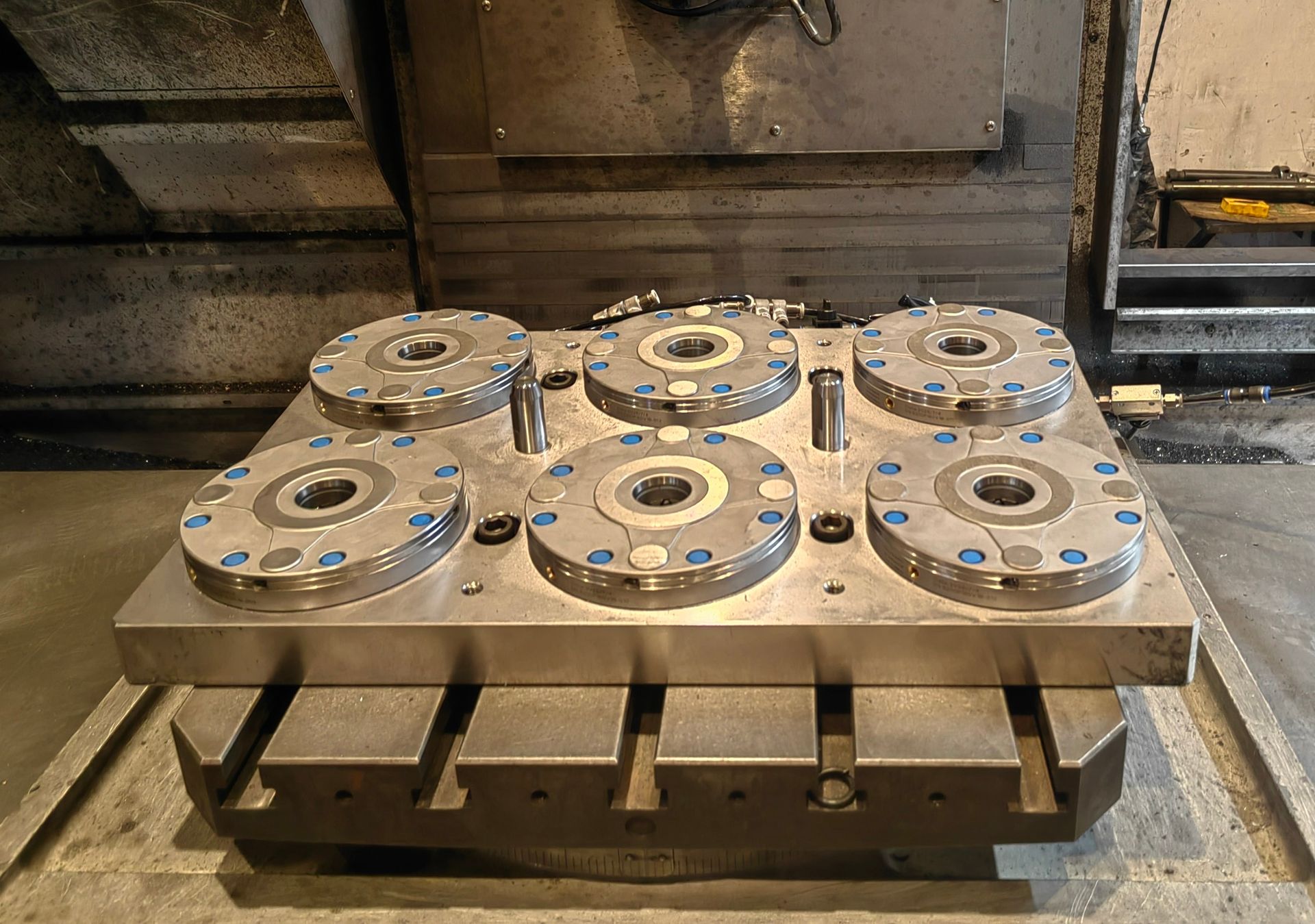

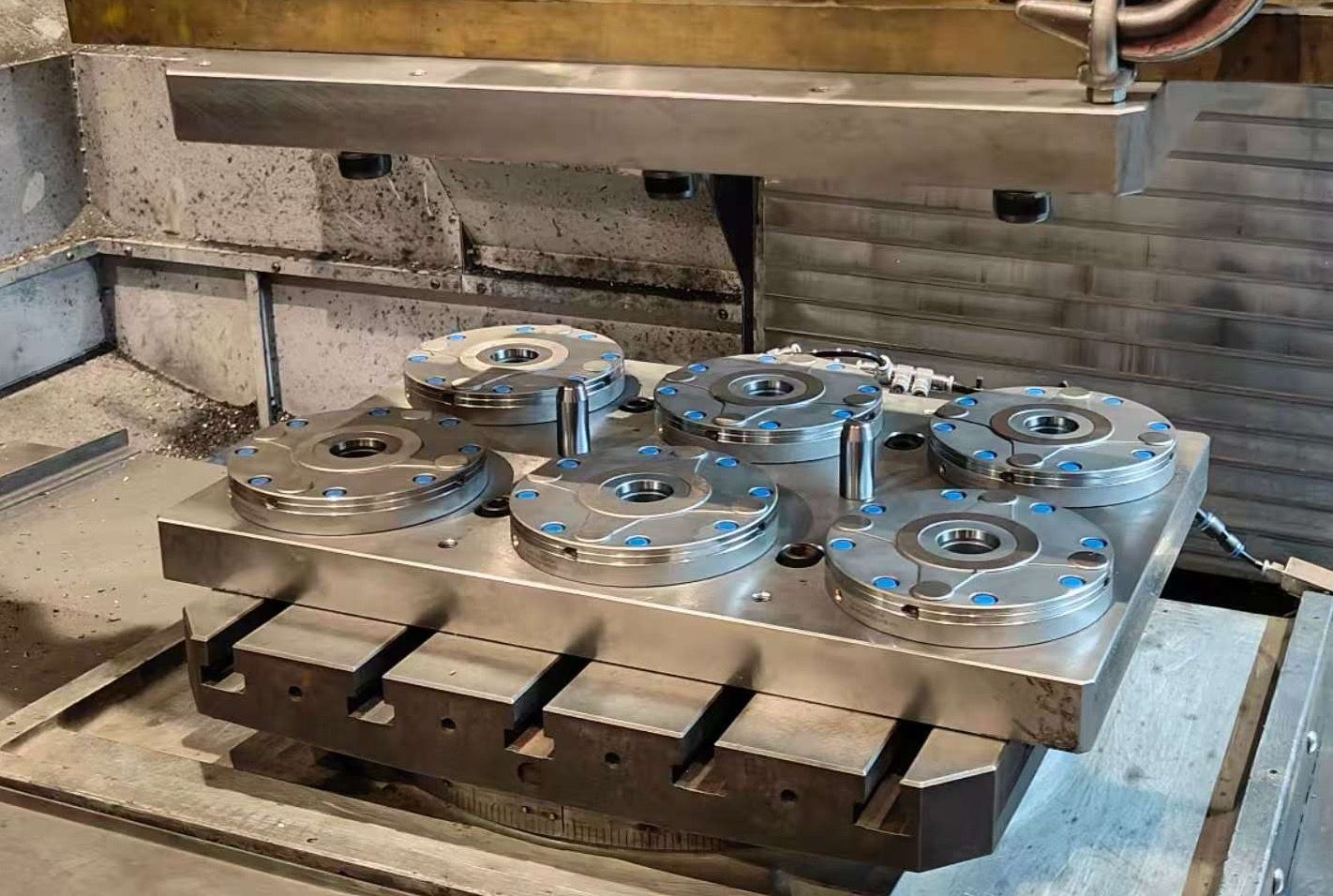

See It In Action: The Power of Instant Changeover

Watch how our Zero-Point Clamping System transforms your workflow. This demonstration showcases the incredible speed and flawless precision of our locking mechanism, allowing for pallet changes in seconds.

(7)%20(1).png?updatedAt=1754553736043)

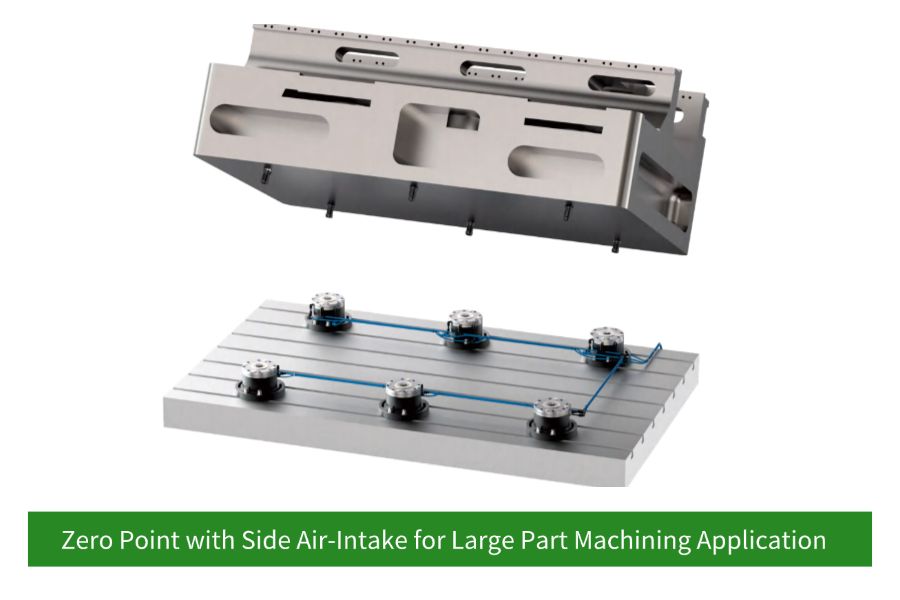

Bottom Inlet Solution Features

- • Flexible taper fit positioning · Repeatable positioning accuracy <0.003mm.

- • High-precision ball lock self-locking structure ensures stability.

- ③⑥ Pneumatic boosting function enhances clamping force.

- ④⑦ Air-tightness testing and surface self-cleaning function.

- ⑤⑧ Pneumatic lock/unlocking and chuck lifting function.

- • Jet cleaning function inside the pull stud hole prevents debris.

- • Air-tightness testing and positioning surface self-cleaning.

Key System Functions

- Mechanical Self-Locking: Maintains 100% clamp force even if air pressure is lost.

- Clamping Force Booster: Optional turbo function increases holding force for heavy-duty jobs.

- Self-Cleaning Air Blast: Integrated channels clear debris before clamping to ensure perfect seating.

- Position Monitoring: Sensor-ready for feedback to confirm clamp/unclamp status for secure automation.

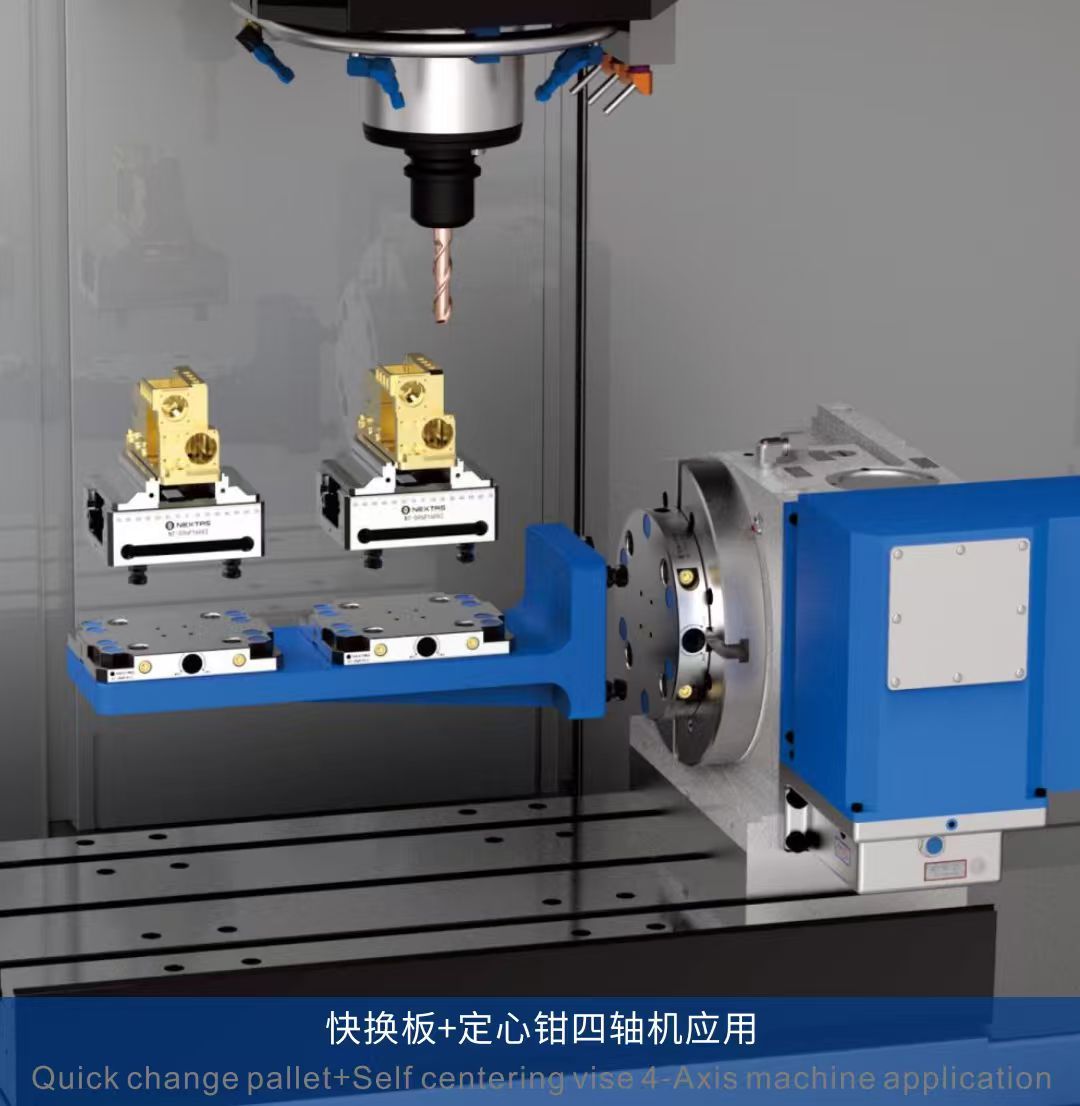

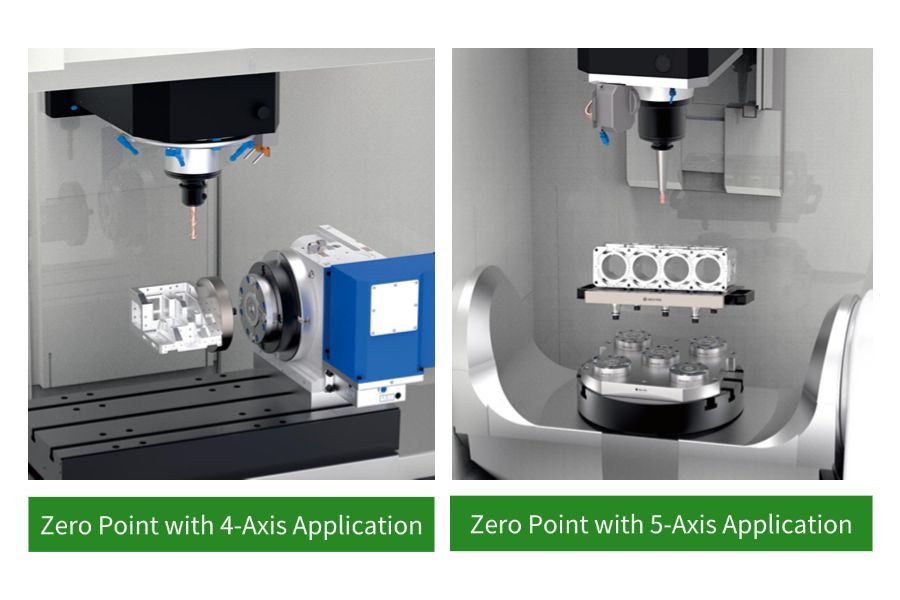

Advanced Manufacturing Applications

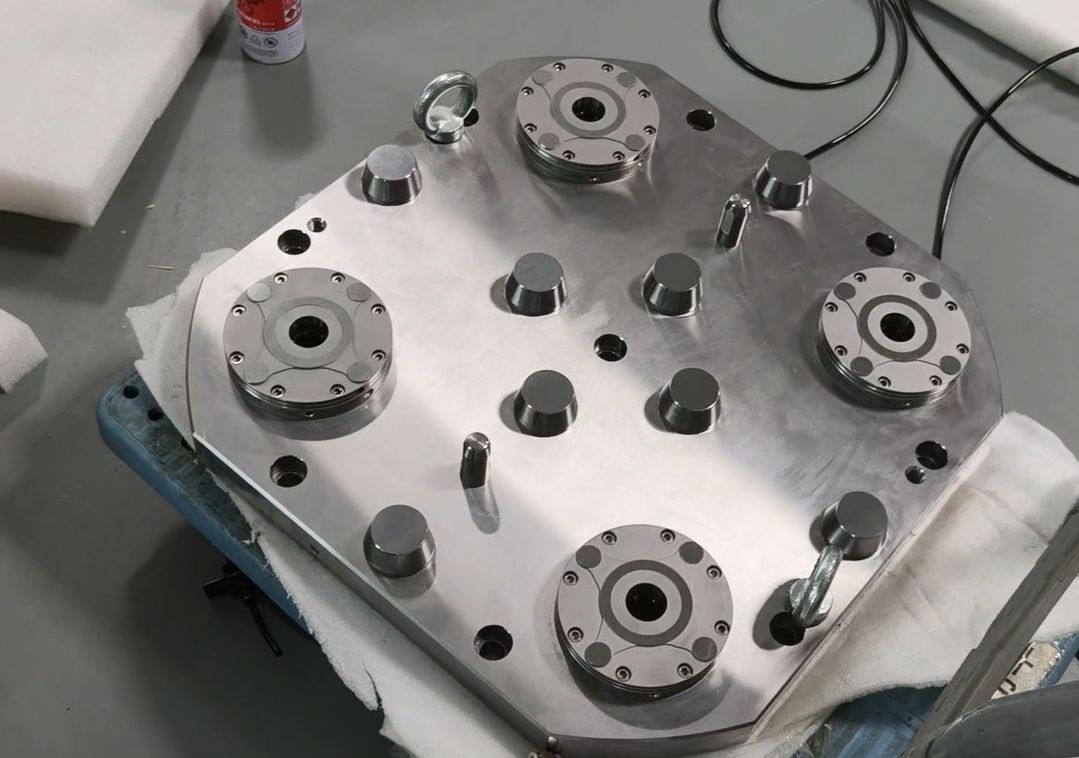

Offline Setup & Palletization

Build fixtures and mount workpieces on pallets while the machine is running, drastically increasing machine uptime.

Multi-Machine Standardization

Use the same setup across multiple machines (3-axis, 5-axis, CMMs) for ultimate flexibility and reduced fixture inventory.

Case Studies

Frequently Asked Questions

How does the 'fail-safe' mechanical locking work?

What is the difference between the 'Bottom Inlet' and 'Side Inlet' solutions?

Can these modules be used for applications other than CNC machining?

What maintenance is required for the zero-point modules?

How do I integrate the system for automated position monitoring?

Resources & Downloads

Complete Your System

Zero-Point Clamping Plates

The ideal foundation. Our plates come with modules pre-installed for easy setup on any machine.

View Details →>

Positioning Pull Studs

The crucial counterpart to our modules. Precision-ground for perfect engagement and repeatability.

View Details →>

Automatic Pallet Changer

Maximize machine uptime with a fully integrated system built around our core technology.

View Details →>

(7).png?updatedAt=1754553737609)