Please enter your email address to receive the product catalog directly in your inbox.

E-Series Automation Chuck

Precision for Automated Manufacturing

The Nextas E-Series Chuck is the definitive solution for high-precision, automated manufacturing. Fully compatible with the EROWA ITS system, this chuck provides a universal interface for electrodes and workpieces across various processes like EDM, milling, and grinding. Its robust design and exceptional repeatability make it the cornerstone of any modern, flexible production environment.

Product Details

The Nextas E-Series Chuck operates on a proven principle of precision and reliability. The chuck's internal mechanism, actuated by compressed air, opens the clamping collet to accept a workpiece holder or electrode. When the air is released, the collet closes with immense force, pulling the holder into a precise, repeatable Z-position against the hardened contact surface. This system not only ensures accuracy but also allows for rapid, automated changes, forming the backbone of a "set up once, machine anywhere" production philosophy.

Built for Durability and Automation

Manufactured from high-grade, rust-proof stainless steel, the E-Series Chuck is engineered to withstand the demanding conditions of EDM and grinding operations. Its sealed design prevents ingress of dielectric fluid and abrasive particles. Integrated connections for air pressure, cleaning, and presence check functions allow for seamless communication with robotic handlers and machine controllers, making it a truly "plug-and-play" component for any automation cell.

Technical Specifications

| Parameter | Specification (Model Example: NEX-C100) |

|---|---|

| Compatibility | EROWA ITS Chucks (ER-036345, etc.) |

| Repeatability | ≤0.002 mm |

| Clamping Power | 6000 N |

| Actuation | Pneumatic, single-acting |

| Operating Pressure | 6 ± 1 bar |

| Connections | Rear or side air connections |

| Body Material | Stainless Steel, rust-resistant |

| Weight | 3.5 kg |

Application Cases

EDM (Electrical Discharge Machining)

The corrosion-resistant construction and high precision make it the industry standard for holding electrodes and workpieces in die-sinking and wire-cut EDM machines.

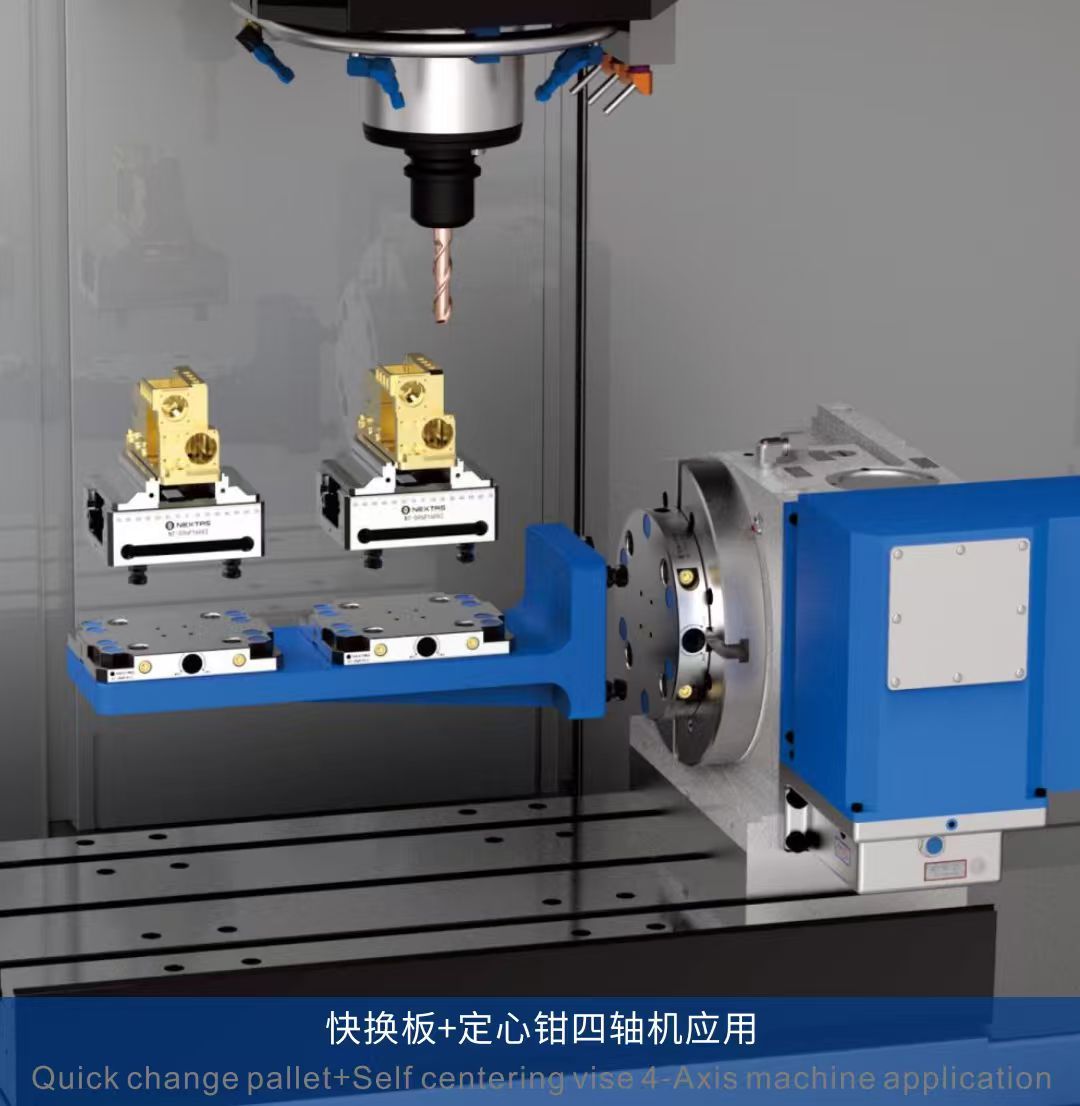

High-Speed Milling

Provides a rigid, stable base for high-speed milling operations. Workpieces can be pre-set offline on pallets and quickly loaded into the machine, maximizing spindle uptime.

Grinding & Jig Grinding

The exceptional repeatability is critical for precision grinding operations, ensuring ultimate accuracy for tight tolerances and fine surface finishes.

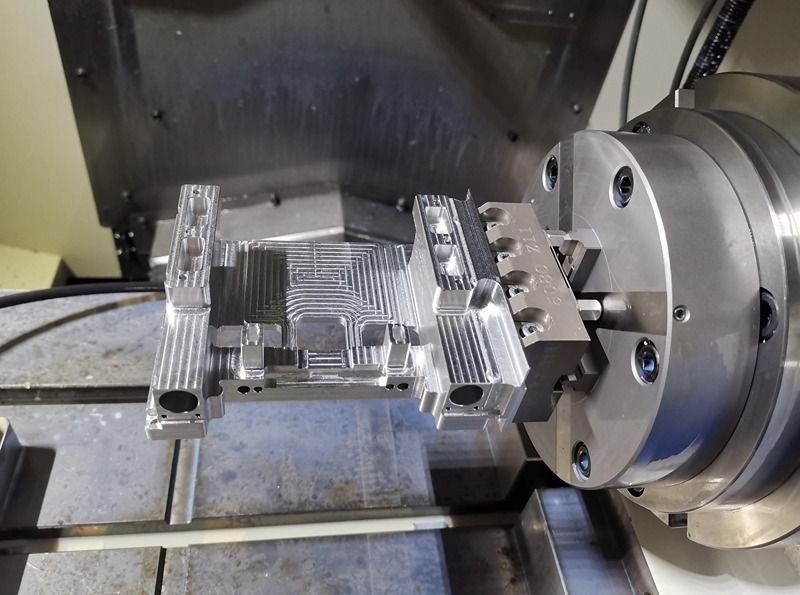

Tool & Mold Making

The ability to move a workpiece between different technologies on the same holder is a game-changer, drastically reducing lead times and improving accuracy.

Real-World Case Studies

Frequently Asked Questions

What is the exact repeatability of the E-Series Chuck, and how is it verified?

The E-Series Chuck guarantees a repeatability of ≤0.002 mm (2 microns). We verify this precision on every unit using certified CMM (Coordinate Measuring Machine) equipment before shipment, ensuring consistent, documented quality.

How does the clamping mechanism work, and what is the clamping force?

It uses a single-acting pneumatic system. Compressed air (6 ± 1 bar) opens the collet. When air is released, powerful springs provide 6,000 N of clamping force, pulling the holder into a precise Z-position. This "normally closed" spring clamping ensures the workpiece remains secure even if air pressure is lost.

What materials are used, and how do they withstand EDM environments?

The chuck body and all critical components are made from high-grade, rust-resistant stainless steel. This material is specifically chosen for its durability and exceptional resistance to corrosion from dielectric fluids and the abrasive particles generated during EDM and grinding.

How does the chuck handle debris in an automated cell?

The chuck is designed for automation with integrated self-cleaning capabilities. It features air-blast ports that direct high-pressure air at the mating surfaces (tapered pins and receivers) during the un-clamping sequence. This automatically clears away chips and fluid, ensuring a clean connection for the next pallet.

Is this chuck fully compatible with EROWA ITS holders and pallets?

Yes, it is 100% compatible with the EROWA ITS system (e.g., ER-036345). You can seamlessly integrate it into your existing tooling setup with any ITS holders, electrodes, or pallets without any modification.

Resources & Downloads

Related Products

Explore other solutions that complement the E-Series Chuck and enhance your production line.

R-Series Chuck

A versatile chuck for various machining applications, offering robust clamping and reliability.

View Details

Self Centering Vise

Precisely centers workpieces of various sizes for accurate milling and drilling operations.

View Details

Automatic Pallet Changer

Maximize machine uptime with seamless, automated pallet changes for continuous production.

View DetailsRelated Articles

Gain insights from our experts on how to optimize your manufacturing processes.