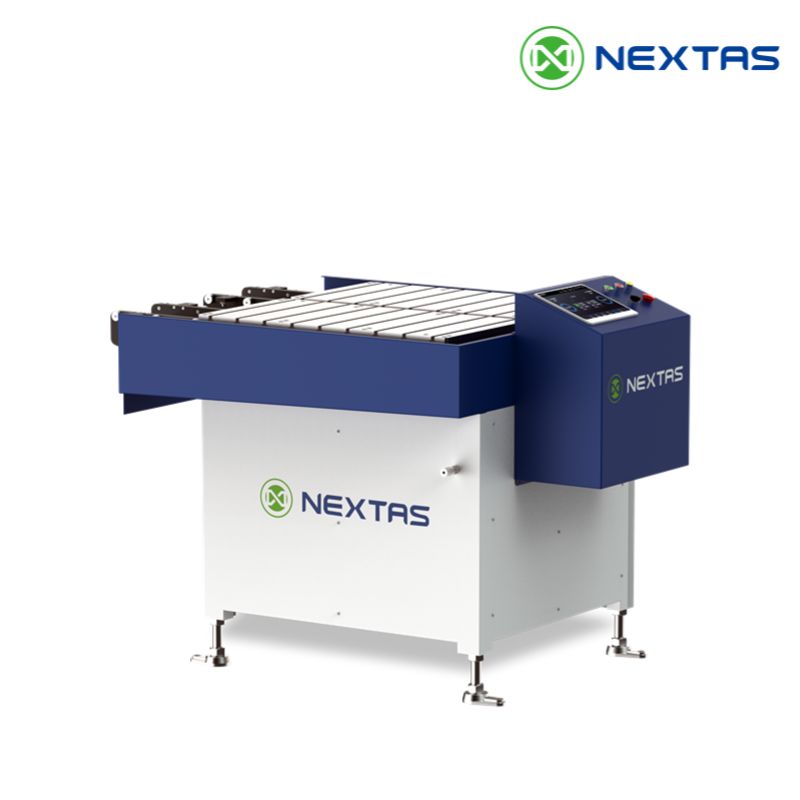

Automatic Pallet Changer (APC)

Your Gateway to 24/7 Unattended Production.

The Nextas Automatic Pallet Changer is the ultimate solution for CNC machine automation. Seamlessly integrated with your existing or new vertical machining centers, our APC transforms your production floor into a flexible manufacturing system (FMS), maximizing spindle uptime and enabling true "lights-out" manufacturing.

Key Features

- Maximize Spindle Uptime: Keep your machines running and making chips, not waiting for manual part changes.

- Lights-Out Manufacturing: Enable unattended operation overnight and on weekends for maximum productivity.

- Ultimate Flexibility: Easily switch between high-mix, low-volume jobs without costly downtime.

- Seamless Integration: Designed for compatibility with a wide range of VMC brands and models.

Engineered for Reliability

The Nextas Automatic Pallet Changer (APC) system is engineered for reliability and performance. It consists of a pallet changing unit that shuttles pallets between a loading station and the machine's work envelope. While the machine is busy on one pallet, the operator can safely set up the next job on the other pallet outside the machine. This dramatically reduces setup time and maximizes the machine's productive hours.

Our APC is more than just hardware; it's a complete productivity solution. It includes intuitive control software that integrates smoothly with your machine's controller (Fanuc, Siemens, Mitsubishi, and more), making operation simple and error-proof. Elevate your manufacturing capabilities, reduce labor costs, and gain a competitive edge with Nextas automation.

Technical Specifications

| Parameter | Details |

|---|---|

| Pallet Size | 500mm x 500mm (Custom sizes available) |

| Max. Payload per Pallet | 300 kg |

| Pallet Change Time | Approx. 30 seconds |

| Control System | Integrated PLC with HMI panel |

| Compatibility | Fanuc, Siemens, Mitsubishi, Heidenhain, and more |

Versatile Across Industries

Aerospace

Ideal for high-precision components with complex geometries and long machining times.

Medical

Perfect for manufacturing surgical instruments and implants with high traceability.

Automotive

Efficiently handles small to medium batch production of various automotive parts.

General Machining

Empowers job shops to increase capacity, take on diverse projects, and improve lead times.

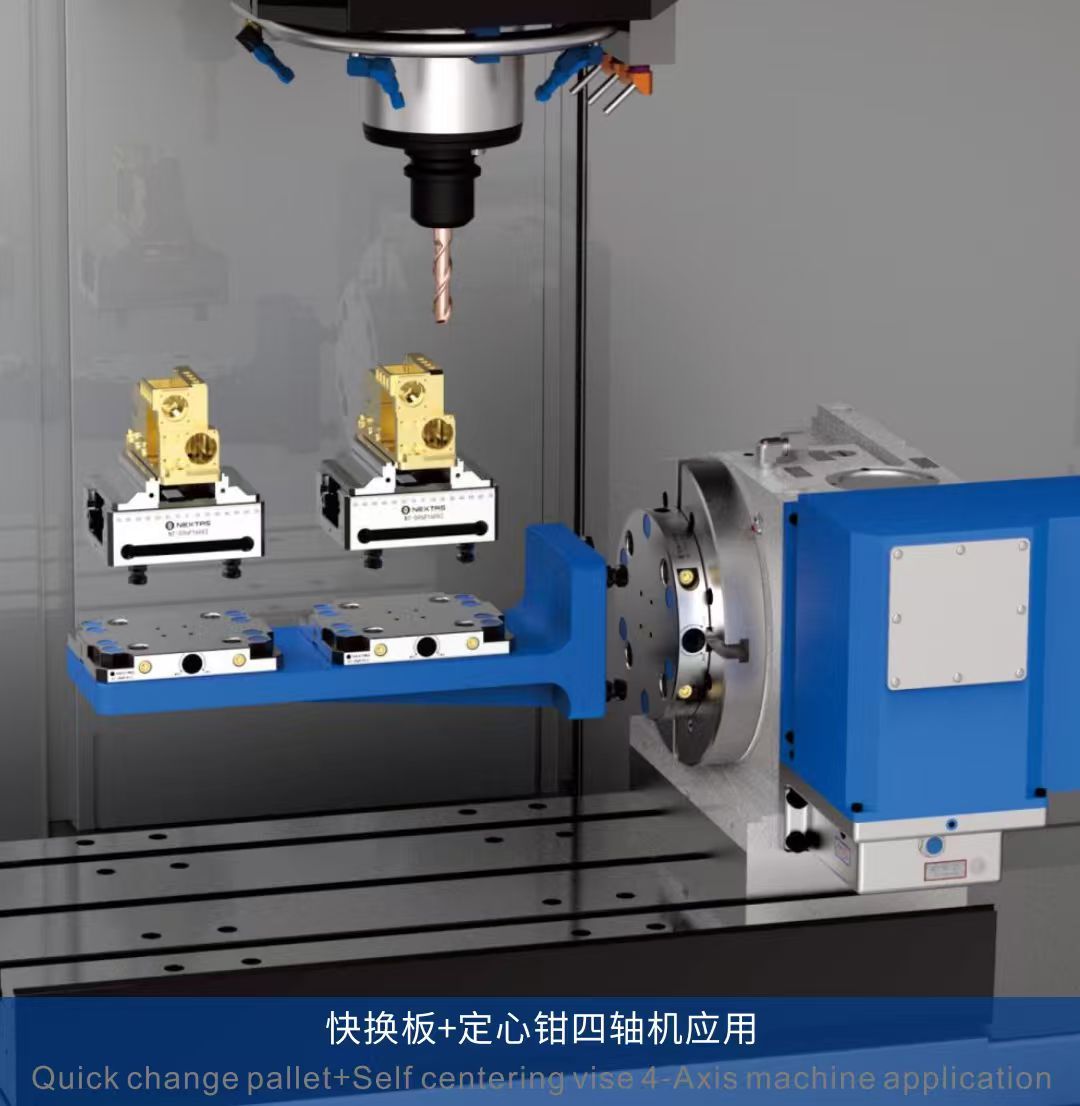

Real-World Applications

Frequently Asked Questions

01 What is Automatic Pallet Changer (APC) and who is it for?

02 What are the key specifications of Automatic Pallet Changer (APC)?

03 Which machines or use cases is Automatic Pallet Changer (APC) compatible with?

04 How is Automatic Pallet Changer (APC) installed or mounted?

05 Where can I get CAD files or technical documentation?

Related Products

Zero Point Clamping System

Achieve setup times in seconds with maximum repeatability. The core of flexible manufacturing.

View Details →

Self Centering Vise

Ideal for 5-axis machining and automated applications, ensuring the workpiece is always perfectly centered.

View Details →

R-Series Chuck

Robust and versatile pneumatic chuck for heavy-duty applications and automated environments.

View Details →