The Nextas Self-Centering Vise: Key to Unlocking 30%+ CNC Machining Efficiency

Published on July 10, 2025

See also: Zero-Point Clamping Plate

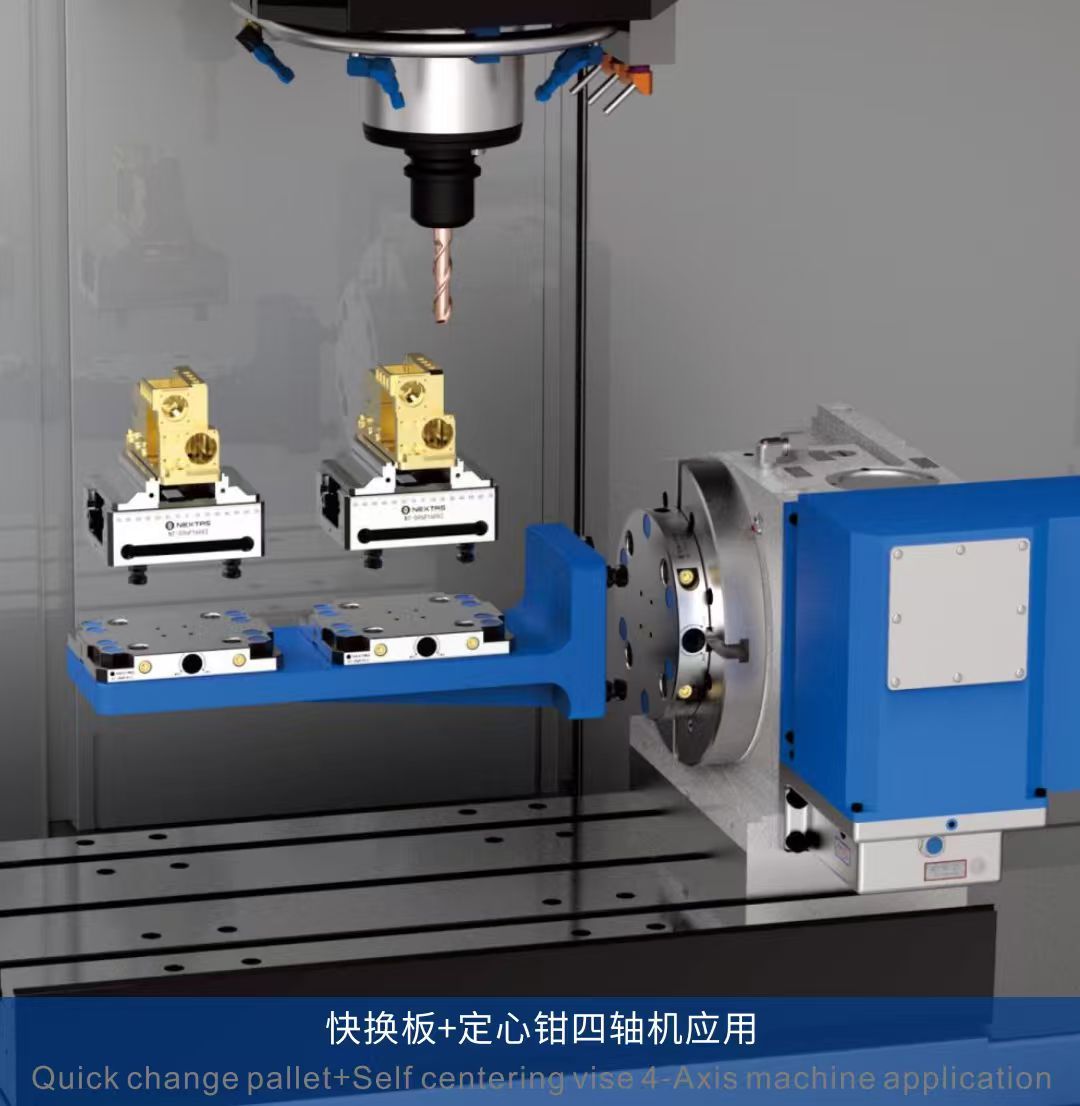

In today's hyper-competitive manufacturing landscape, efficiency is the ultimate determinant of profitability and market leadership. For precision machining shops, finding the right tools is paramount. The Nextas Self-Centering Vise was engineered for this very purpose, proven to boost overall machining efficiency by over 30%. When paired with the Nextas Zero-Point System, it achieves a staggering 90%+ reduction in CNC changeover times.

The Bottleneck of Traditional Workholding: A Dual Challenge of Time and Precision

Traditional vises demand significant time for manual adjustments and alignment. This process not only slows down production but is also prone to human error, compromising machining accuracy and creating a major bottleneck. Every part changeover means repeating the tedious alignment process, accumulating substantial machine downtime.

Zero-Hassle Alignment: The Core Advantage of Nextas

The superior performance of the Nextas Self-Centering Vise lies in its advanced design. Its self-centering mechanism automatically and precisely aligns the workpiece to the spindle centerline during clamping. This eliminates manual adjustments and guesswork, drastically cutting down setup time. Your team can now focus on what they do best—making chips—instead of tedious machine-side preparations.

A 90% Leap in Efficiency: The Revolutionary Breakthrough with the Zero-Point System

When setup time is constraining your efficiency, combining the Nextas Self-Centering Vise with our Zero-Point Quick-Change System is a game-changer. This system provides a standardized and highly repeatable (≤.002 mm) positioning interface. Swapping workpieces or entire fixtures no longer requires tedious realignment, reducing a process that took hours to mere minutes.

This advantage is especially critical for high-mix, low-volume production, dramatically minimizing machine idle time and maximizing your equipment's earning potential.

Broad Compatibility: Seamless Integration with Any CNC Platform

Another significant advantage of the Nextas Self-Centering Vise is its universal compatibility. Whether you operate 3-axis, 4-axis, or full 5-axis machining centers—or even horizontal, vertical, or multi-tasking machines—this vise integrates seamlessly without complex retrofitting. This versatility makes it the ideal choice for any shop, from simple part manufacturing to complex component production.

Related Articles

Related Products

Frequently Asked Questions (FAQ)

What makes a self-centering vise different from a standard machinist vise?

A standard vise has one fixed jaw and one moving jaw, meaning the workpiece's center shifts depending on its size. A self-centering vise, like the Nextas model, has two jaws that move symmetrically towards the center. This ensures the workpiece datum is always precisely on the spindle centerline, regardless of part size, which is critical for 4-axis and 5-axis machining setups.

What jaw options are available for this vise?

To maximize versatility, we offer a wide range of interchangeable jaw systems. This includes hardened serrated jaws for aggressive roughing, smooth ground jaws for finishing operations, and machinable soft jaws. Soft jaws allow you to create custom part-specific profiles, providing perfect grip and support for complex geometries.

How much clamping force does the vise generate?

The Nextas Self-Centering Vise utilizes a robust, high-force mechanical spindle. This design generates up to 40 kN of clamping force, providing exceptional rigidity and vibration damping. This makes it perfectly suitable for both high-precision finishing passes and heavy rough milling operations where stability is crucial.