Please enter your email address to receive the product catalog directly in your inbox.

R-Series Manual Chuck

Robust Precision, Simplified.

The Nextas R-Series Manual Chuck provides a reliable, high-precision foundation for your workshop. Fully compatible with the System 3R tooling standard, this chuck offers exceptional versatility for job shops and production environments alike. Its simple, robust manual clamping mechanism ensures a secure grip and excellent repeatability without the need for pneumatic or hydraulic lines, making it perfect for quick setups on any machine.

Core Advantages

- High Repeatability: Achieves a positioning accuracy of ≤0.005mm, allowing for confident transfer of workpieces between setups and machines.

- Simple Manual Clamping: Fast and secure clamping with a single lever or key. No need for external power sources, simplifying installation and use.

- System 3R Compatibility: Designed to seamlessly integrate with the widely used System 3R standard, including pallets, holders, and electrodes.

- Hardened & Ground Body: Constructed from high-quality tool steel, hardened and precision-ground for maximum durability, rigidity, and a long service life.

Product Details

Discover the engineering and design behind the R-Series Chuck.

Precision Clamping, Effortlessly

The Nextas R-Series Chuck simplifies precision workholding. The manual clamping mechanism is straightforward yet powerful. A simple turn of a clamping key actuates the internal locking system, drawing the reference element (pallet or holder) securely against the Z-reference faces. This direct mechanical action provides excellent tactile feedback and ensures a consistently strong and stable clamp, giving the operator full confidence in the setup. The design eliminates the complexity of air or hydraulic lines, making it exceptionally easy to install and move between different machines.

Engineered for Versatility

Manufactured from high-grade tool steel and hardened for wear resistance, the R-Series Chuck is built to last. Its low-profile design provides excellent access for tools and spindles, making it suitable for a wide range of applications, from vertical milling to sinker EDM. The universal System 3R-compatible interface means you can standardize your workholding across the entire workshop, streamlining your processes and reducing the need for multiple, disparate systems.

Technical Specifications

| Parameter | Specification (Model Example: NEX-R80M) |

|---|---|

| Compatibility | System 3R (MacroMagnum, etc.) |

| Repeatability | ≤0.005 mm |

| Clamping Power | ~8000 N |

| Actuation | Manual, with clamping key/lever |

| Required Torque | ~20 Nm |

| Indexing Positions | 4 x 90° |

| Body Material | Hardened Tool Steel |

| Weight | 5.0 kg |

Application Fields

Versatile solutions for a wide range of machining tasks.

EDM & Milling

Its robust build handles milling forces, while its precision is perfect for setting up electrodes and workpieces for EDM operations.

Job Shops & Prototyping

Ideal for high-mix, low-volume work. The manual chuck allows for extremely fast and precise changeovers between jobs.

Quality Control & Inspection

Move workpieces directly from machine to inspection, ensuring consistent measurement results with the same reference system.

Offline Setup

Mount workpieces onto pallets at a separate station while the machine runs, making swaps quick and simple to maximize uptime.

Real-World Case Studies

Frequently Asked Questions

01. How does the R-Series Manual Chuck ensure its ≤0.005mm repeatability?

02. What is the main difference between the R-Series and an automated chuck (like the E-Series)?

03. Is the "System 3R Compatibility" 100% interchangeable?

04. What maintenance is required for the R-Series Manual Chuck?

05. Can I mount the R-Series chuck onto any machine table?

Resources & Downloads

Related Products

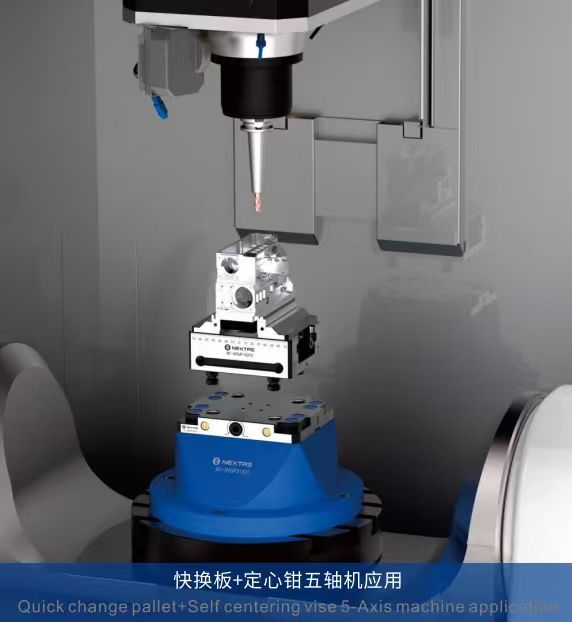

Self Centering Vise

Provides precise centering for various workpiece sizes, ideal for 5-axis machining.

View Details →

Zero Point Clamping System

Drastically reduces setup times with quick and repeatable positioning for fixtures and workpieces.

View Details →

Automatic Pallet Changer

Boosts productivity by enabling unattended machine operation and rapid pallet swaps.

View Details →