5-Axis Self-Centering Vise: What Makes It Ideal for Complex Machining?

Published on July 30, 2025

See also: High-Precision 5-Axis Self-Centering Vise

In the realm of precision manufacturing, complex parts with multiple faces and tight tolerances demand more than conventional clamping. The 5âaxis selfâcentering vise has emerged as a gameâchanger because it secures workpieces symmetrically while allowing full spindle access around them. This article examines what sets these vises apart and why theyâre indispensable for advanced multiâaxis machining.

Simultaneous Precision and Versatility

Traditional vises struggle when parts must be rotated across X, Y, Z and rotational axes. A 5âaxis selfâcentering vise uses a symmetric clamping mechanism that automatically centers the workpiece and applies equal force from both jaws. Because the workpiece stays perfectly centered as the machine traverses complex tool paths, features like holes, slots and contours line up on every face without the need for secondary setups.

Key Design Features That Drive Performance

- HighâStrength, LowâProfile Construction: A compact body maximizes spindle clearance for deep cuts and overhanging features. Hardened steel or aluminum alloys balance rigidity with low mass, reducing vibration during highâspeed machining.

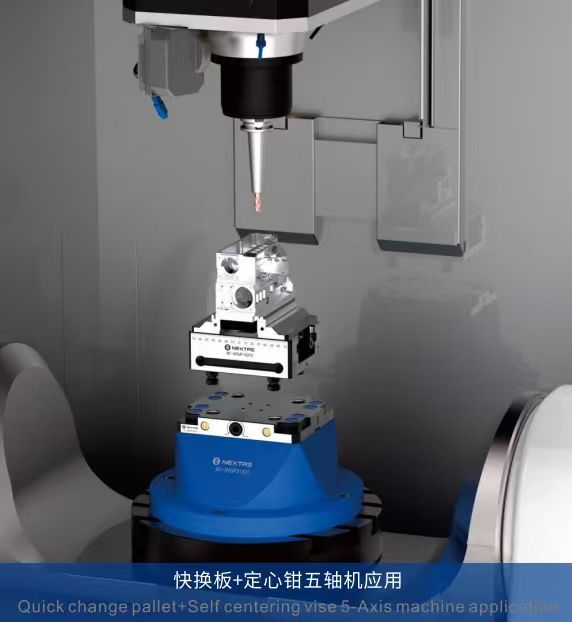

- DualâJaw Synchronization: Internal gears or cams ensure both jaws move in unison, centering the workpiece with micronâlevel accuracy. This eliminates manual alignment and the human errors associated with conventional vises.

- Modular Compatibility: Many models integrate with quickâchange base systems, such as zeroâpoint clamping plates, for rapid job changeovers. The ability to swap fixtures in minutes keeps highâmix production running smoothly.

- Adjustable Clamping Force: Whether machining delicate aerospace components or rugged industrial parts, operators can fineâtune clamp pressure to prevent deformation while maintaining a secure grip.

Why Complex Machining Canât Afford to Skip It

- Eliminates Secondary Operations: By giving the spindle full 5âaxis access, all faces of a part can be machined in one setup. This avoids repositioning and reduces cumulative alignment error.

- Reduces Scrap Rates: Automatic centering drastically lowers the risk of offâaxis errors. Shops adopting 5âaxis selfâcentering vises report significantly fewer scrapped parts versus traditional clamping.

- Boosts Productivity: Quick setup times combined with uninterrupted multiâaxis cutting shorten cycle times. Many manufacturers see doubleâdigit reductions in perâpart machining time after switching to selfâcentering vises.

Choosing the Right 5âAxis SelfâCentering Vise

Not all vises are created equal. Consider these factors when selecting a model for demanding work:

- Accuracy Rating: Look for repeatability within ±0.02 mm to meet tight tolerances.

- Clamping Range: Make sure the vise accommodates your smallest and largest partsâfrom small 10.0 mm components to larger 320Â mm workpieces.

- Material Compatibility: For highâtemperature alloys such as Inconel, choose jaws and lubricants designed for heat and wear resistance.

- Certifications: Models compliant with ISOÂ 9001 or aerospace standards like ASÂ 9100 are essential for critical applications.

Final Thoughts

Complex 5âaxis machining leaves no room for error. A highâquality selfâcentering vise isnât just a fixtureâitâs a precision partner that ensures parts meet specifications, reduces waste and keeps production on schedule. When youâre ready to elevate your machining capability, invest in a vise that delivers symmetric clamping, modular compatibility and micronâlevel repeatability.