How HighâPrecision Pneumatic Vises Power Uninterrupted Automation in Manufacturing

Published on August 20, 2025

See also: High-Precision Pneumatic Vise

In the era of smart factories, every component in an automated line plays a critical role in balancing precision and productivityâand the highâprecision pneumatic vise stands out as a silent workhorse. Its unique pneumatic performance isnât just about clamping force; itâs the backbone of seamless automation, especially for industries like aerospace manufacturing and medical part machining where zero errors and 24/7 operation are nonânegotiable.

Pneumatic Performance: The Foundation of Automated Reliability

Unlike manual or hydraulic vises, a highâprecision pneumatic vise relies on compressed air for actuationâdelivering consistent, repeatable clamping (often within ±0.005 mm) thatâs essential for automated workflows. This pneumatic advantage eliminates human variability: no more overâtightening that damages delicate medical parts, or underâclamping that risks slippage during aerospace component machining. The airâdriven design also ensures fast response timesâclamping and releasing in secondsâlaying the groundwork for rapid changeovers. Pneumatic systems generally have long operating lives and require little maintenance.

Machine Program Control: Syncing with Automated Systems

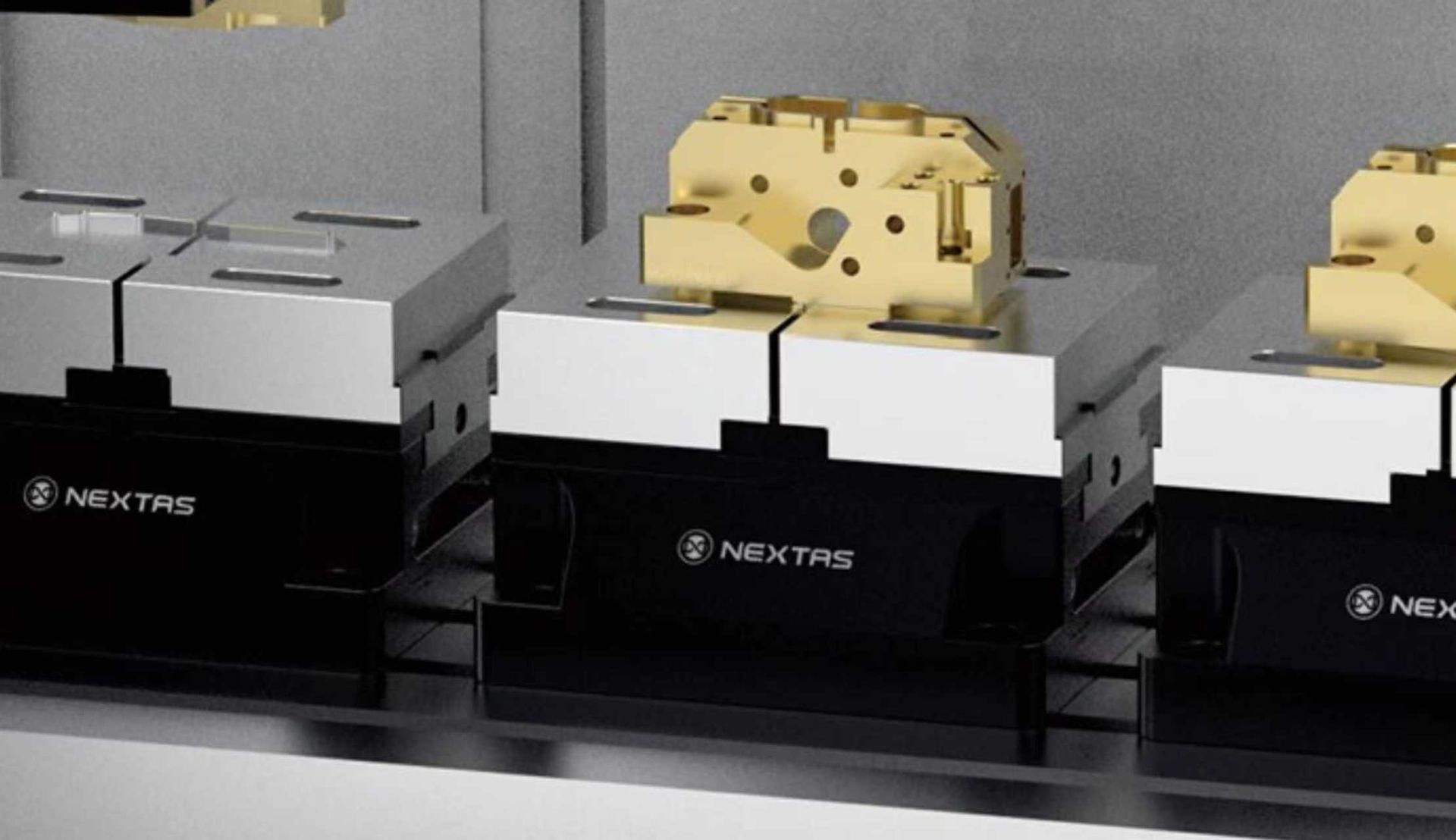

What truly integrates highâprecision pneumatic vises into modern automation is their ability to be controlled via machine tool programs. CNC machines can send realâtime signals to adjust clamping force, activate safety locks or trigger releaseâall without manual intervention. For example, in a medical part machining line, the vise automatically tweaks pressure when switching from aluminum to titanium workpieces, ensuring optimal grip without compromising part integrity. This programmability turns âsetâitâandâforgetâitâ?into a reality.

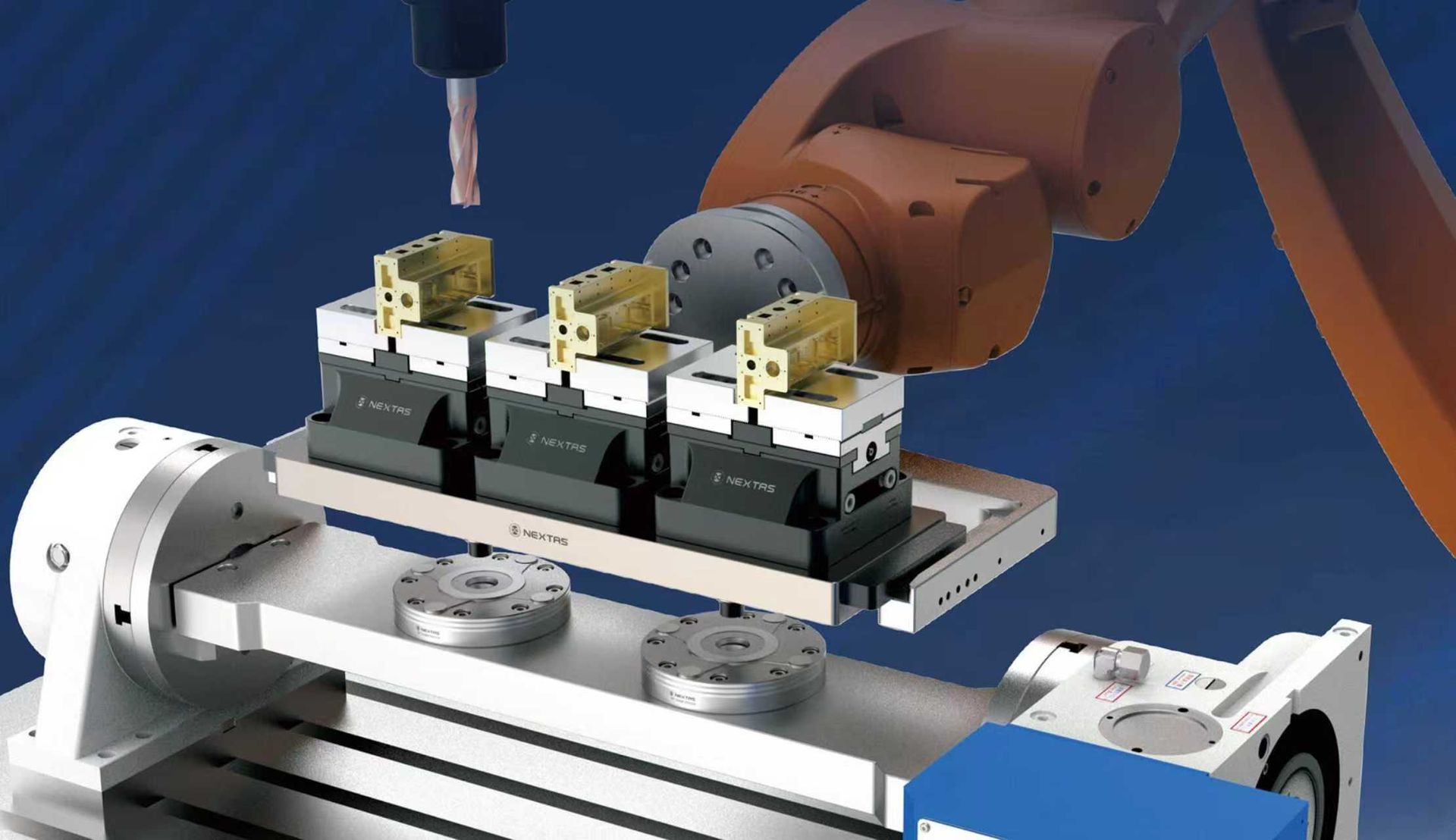

Collaboration with Robotic Arms: Streamlining LoadâandâClamp Cycles

The magic of automation happens when tools work in harmonyâand highâprecision pneumatic vises pair seamlessly with robotic arms. As the robot executes its gripping and placing motions, the viseâs pneumatic actuation syncs perfectly: the robot positions a workpiece, the vise clamps instantly, and once machining ends, it releases just as the robot returns to load the next part. This coordination cuts changeover time by 80% or more compared to manual setups.

Enabling 24/7 Uninterrupted Operation

For manufacturers chasing maximum uptime, the highâprecision pneumatic vise is a gameâchanger. Its durable pneumatic components (resistant to wear and debris) and âfailâsafe lockedâ?design ensure it can run roundâtheâclock. In lightsâout factoriesâwhere production of goods is fully automated without requiring human labourâCNC machines can run unattended, keeping lines moving even overnight. Lightsâout manufacturing isnât science fiction; robotâbuilt robots at Fanuc run unsupervised for weeks, proving that 24/7 automation is achievable.

Why It Matters for Specialized Industries

In aerospace manufacturing, where parts like turbine blades require micronâlevel precision, the viseâs consistent clamping prevents misalignment that would ruin expensive materials. In medical part machining, its gentleâyetâsecure grip protects fragile components like surgical instruments, avoiding costly scrap. For any automated line, itâs not just a clamping toolâitâs a bridge between precision, speed, and uninterrupted productivity.

Conclusion

As automation evolves, the highâprecision pneumatic vise remains a nonânegotiable component for factories aiming to stay competitive. Its pneumatic performance, machine programmability, and robotic compatibility donât just boost efficiency â?they redefine whatâs possible for 24/7, errorâfree manufacturing.

Frequently Asked Questions

What is the repeatability of your zero-point systems?

We guarantee a repeatability of ±0.002 mm. All products are verified on certified CMM equipment before shipment to ensure consistent quality for every part.

What materials are your core components made from and what is their hardness?

Our core components, such as clamping pins and receivers, are crafted from high-hardenability alloy steel. They undergo a proprietary heat treatment process to achieve a surface hardness of HRC 58-62, ensuring exceptional wear resistance and long-term stability.

How does the self-cleaning function work in your automation chucks?

Our automation chucks feature integrated air-blast channels. During the un-clamping sequence, a high-pressure air blast is directed at the mating surfaces (tapered pins and receivers) to clear away chips, coolant, and other debris. This ensures a clean and precise connection for the next pallet, which is critical for maintaining repeatability in automated cells.

Do you offer customized workholding solutions for unique applications?

Absolutely. While we offer a comprehensive standard product line, our engineering team specializes in developing custom solutions. We can design and manufacture bespoke fixtures, pallets, and clamping systems tailored to your specific workpiece geometry, machine specifications, and production goals. Contact us to discuss your project.

For 5-axis machining of thin-walled or delicate parts, what workholding do you recommend?

For delicate or thin-walled components where distortion is a concern, we highly recommend our Dovetail Fixtures. They provide exceptional clamping force with minimal material engagement (e.g., a 3mm dovetail) on the raw stock. This low-profile clamping allows for maximum tool access (5-side machining) while applying clamping forces in a direction that minimizes part deformation, ensuring high precision and stability.

How does your Self-Centering Vise maintain accuracy over time?

Our self-centering vises achieve high precision (centering accuracy of ±0.005mm) through a hardened and precision-ground leadscrew and nut system. More importantly, they feature an adjustable backlash-free nut design. This allows for compensation of any potential wear over years of use, enabling the vise to be recalibrated back to its original high accuracy, ensuring a long and precise service life.

What is the typical clamping force of a high-precision pneumatic vise, and is it adjustable?

Our high-precision pneumatic vises are engineered to provide substantial clamping force, often ranging from 2,500N to over 6,000N, depending on the model and input air pressure. A key feature for automation is that this force is highly adjustable and repeatable. By regulating the input air pressure (e.g., from 5 to 7 bar), you can precisely control the clamping force, making it ideal for holding delicate parts without distortion or securing heavy blocks for aggressive machining.

How do Nextas pneumatic vises ensure reliability in harsh, high-debris machining environments?

Our vises are designed from the ground up for automated environments, which are often filled with chips and coolant. They feature a fully sealed design to protect the internal leadscrew and pneumatic components. Additionally, they incorporate a positive air pressure system that continuously flushes the internal mechanism, preventing any ingress of contaminants. This robust, sealed-and-purged design is fundamental to ensuring long-term reliability and maintaining precision with minimal maintenance.

Can your pneumatic vises be integrated with any CNC machine or robot controller?

Yes, integration is a core part of their design. Our pneumatic vises operate using standard pneumatic solenoid valves, which can be controlled by a simple M-code signal from any CNC machine's controller. For robotics, the same solenoid can be triggered by the robot controller's I/O, allowing for seamless handshaking. We also offer optional sensor feedback to confirm the 'clamped' or 'unclamped' state, providing a closed-loop signal for safe, fully-automated 'load-and-go' operation.