Please enter your email address to receive the product catalog directly in your inbox.

Pallet Changer System

Tailored Solutions for Industrial Efficiency

Pallet Changer System is a tailored solution engineered to resolve pain points in industrial manufacturing. Refined through iterative R&D, it adapts to diverse application needs across multiple sectors. The product line is categorized into two core series—Manual Pallet Changer System and Automatic Pallet Changer System—empowering enterprises to cut costs, boost efficiency, and enhance market competitiveness.

Core Technical Highlights

- Tapered-Surface Positioning: Ensures stable clamping and high repeat positioning accuracy.

- Pressurized Clamping: Piston-driven mechanical self-locking structure delivers high-strength output.

- Smart Detection: Built-in air tightness detection verifies positioning and feeds back to CNC.

- Self-Cleaning: Automatic air-blow ports remove debris from datum surfaces for consistent accuracy.

Pallet Style Options

Aluminium Pallet

Material: Aluminium Alloy

Size: Adaptable to machine stroke

T-Slot Pallet

Material: Martensitic Stainless Steel

Size: Adaptable to machine stroke

Magnetic Pallet

Material: Martensitic Stainless Steel

Size: Adaptable to machine stroke

Zero Point Pallet

With Zero Point Positioner

Material: Martensitic Stainless Steel

Manual Pallet Changer System

Key Advantages

-

Stable Loading & Unloading

Flexible dual-station design supports front or side-mounted loading, enabling high-mix, low-volume production.

-

Quick Loading & Processing

Completes full layout clamping and rapid retooling in just a few seconds.

-

Efficiency & Utilization Boost

Offline loading and fast machine transfer enhance equipment utilization significantly.

-

Safe & Labor-Saving

External clamping allows quick, effortless positioning via simple operation, reducing labor intensity.

Technical Specifications (Manual)

| Control System | Manual push control |

| Compatible Systems | Mitsubishi, FANUC, Brother, KND, etc. |

| Delivery Load | 100 Kg |

| Air-tightness Range | ± 0.01 mm |

| Max Load | 300 Kg |

| Specification | V4 Positioning Datum |

| Repeat Accuracy | < 0.005 mm |

| Clamping Force | 40,000 N |

| Max Lifting Load | 850 Kg |

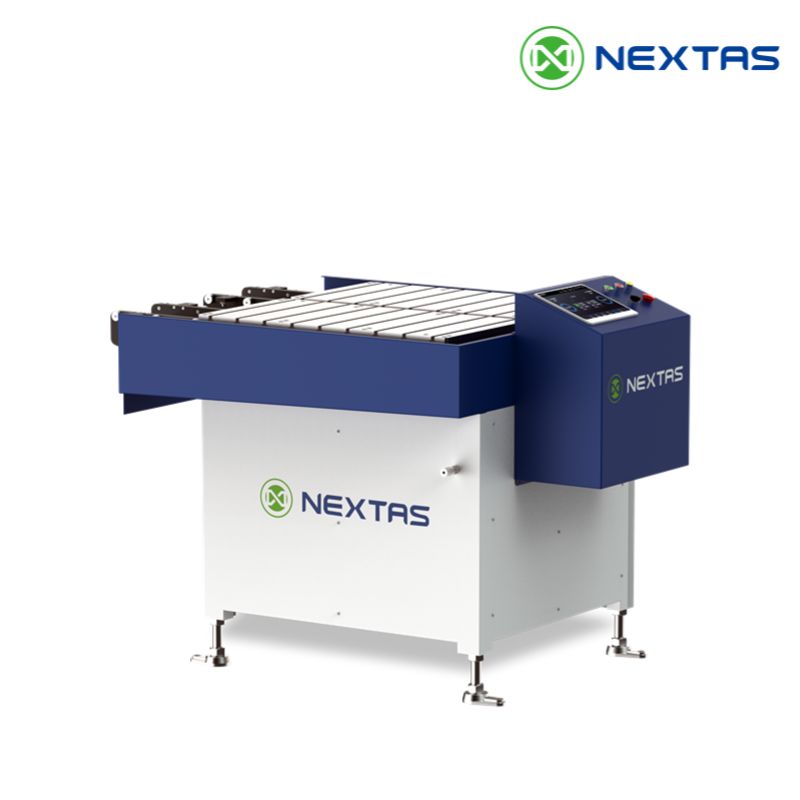

Automatic Pallet Changer System

Technical Specifications (Automatic)

| Control System | NEXTAS |

| Compatibility | Mitsubishi, FANUC, Brother, KND, etc. |

| Communication | EtherNet/IP, ModbusTCP, Socket, PROFINET |

| System Features | Dual-station, product editing, output monitoring, capacity statistics |

| Delivery Speed | 300 mm/s |

| Movement Accuracy | 0.02 mm |

| Max Load | 2,000 Kg |

| Specification | V6 Positioning Datum |

| Repeat Accuracy | < 0.005 mm |

| Clamping Force | 60,000 N |

Key Advantages

-

Robust External Clamping

High-strength rigid bracket structure supporting custom heavy-load configurations. Compact footprint with integrated safety protection.

-

Micron-Level Precision

Adopts zero-point positioning principles, consistently maintaining <0.005mm repeat accuracy for stable, ultra-precise clamping.

-

Broad VMC Compatibility

Compatible with multiple VMC brands. Supports front or side pallet exchange with customizable pallet sizes.

-

Smart Integrated Control

Self-developed control system supports MES/SCADA integration for unattended automated loading, management, and data visualization.

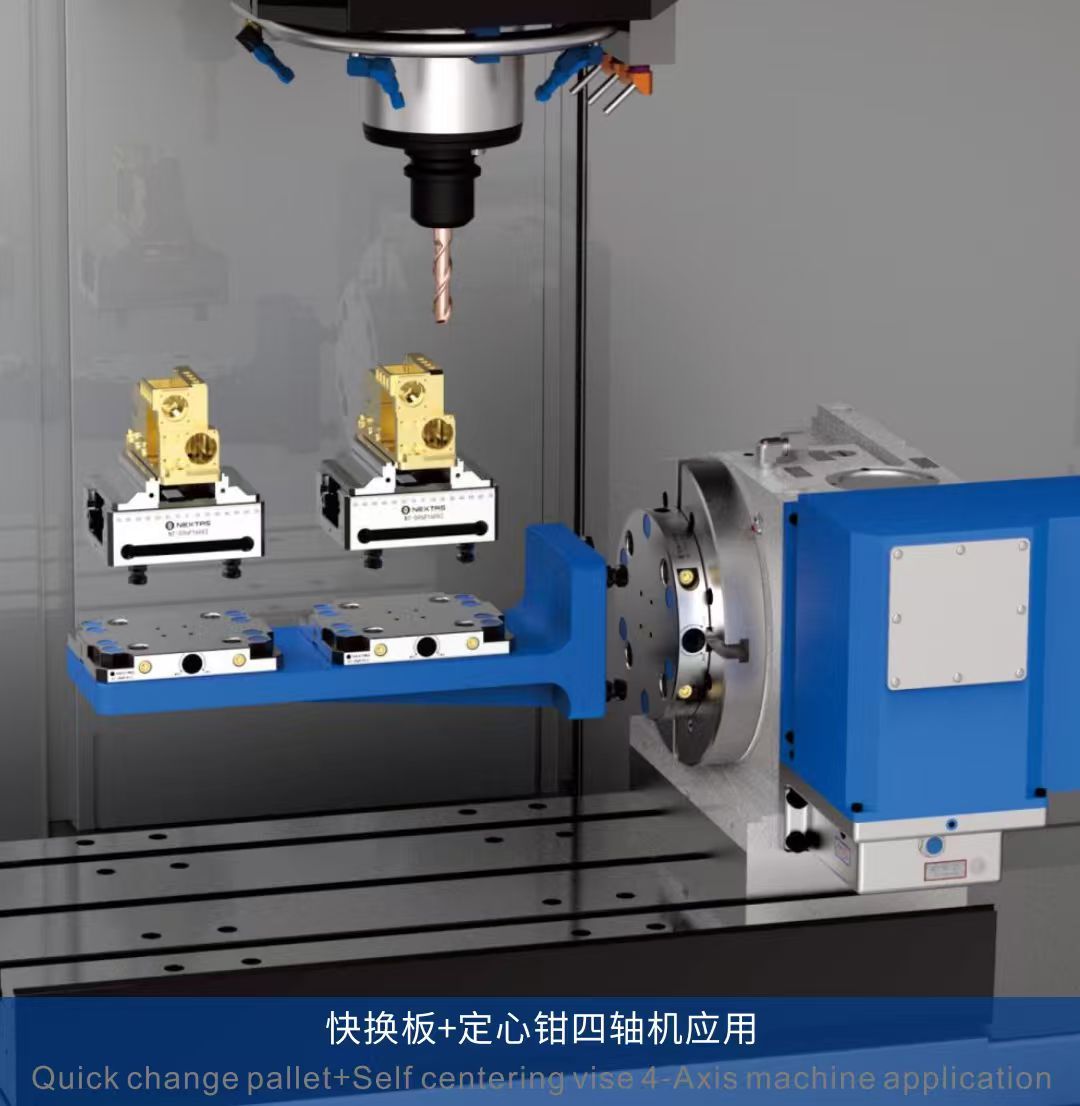

Real-World Applications

Frequently Asked Questions

01 What is an Automatic Pallet Changer (APC) and who is it for?

02 What are the key specifications of the Nextas APC?

03 Which CNC machine controllers is the APC compatible with?

04 What safety features are included in the APC system?

05 How does the APC handle high-mix, low-volume (HMLV) production?

06 What is the installation and integration process like?

07 What is the typical Return on Investment (ROI) for an APC?

08 Where can I get CAD files or technical documentation?

Related Products

Zero Point Clamping System

Achieve setup times in seconds with maximum repeatability. The core of flexible manufacturing.

View Details →

Self Centering Vise

Ideal for 5-axis machining and automated applications, ensuring the workpiece is always perfectly centered.

View Details →

R-Series Chuck

Robust and versatile pneumatic chuck for heavy-duty applications and automated environments.

View Details →