Please enter your email address to receive the product catalog directly in your inbox.

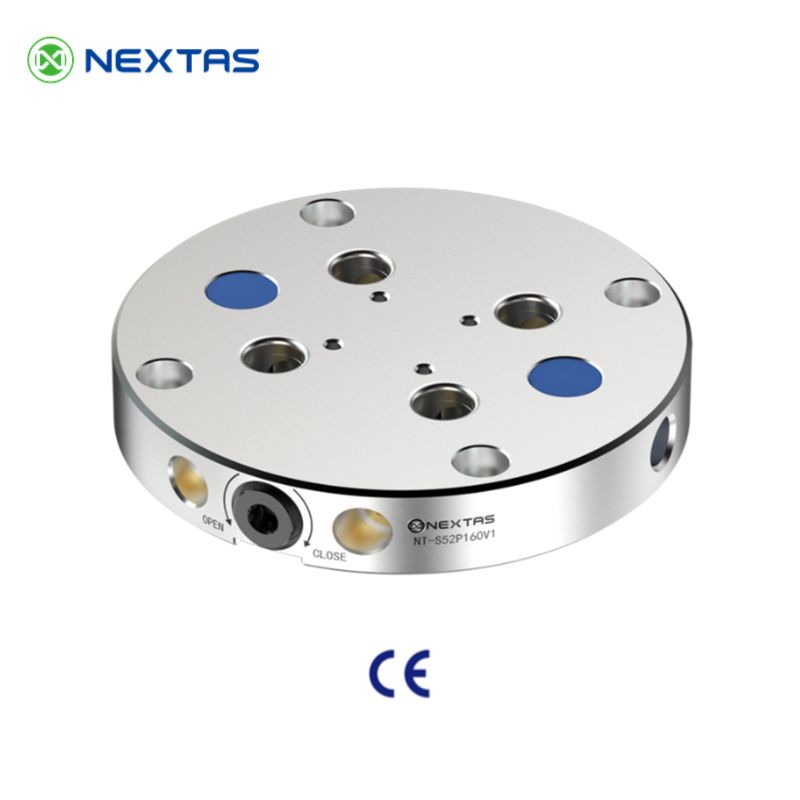

Zero-Point Clamping Plate

The Foundation for Ultimate Flexibility

The Nextas Zero-Point Clamping Plate is the fastest way to implement a modular, quick-change system on your machine tool. By providing a standardized, precision-ground base with integrated zero-point clamping modules, it transforms your machine bed into a highly flexible and productive platform.

Core Advantages

- Standardized Machine Interface: Instantly create a universal grid on your machine table, allowing any fixture or pallet to be mounted with perfect alignment every time.

- Exceptional Rigidity and Stability: Precision-ground from high-grade materials, our plates provide a solid, stable base that absorbs vibration and withstands heavy cutting forces.

- True Modularity: Available in various sizes and configurations (single, dual, quad-module) to fit any machine table and application, from small vises to large tombstone fixtures.

- Plug-and-Play Implementation: Dramatically simplifies the adoption of a zero-point system. Simply bolt the plate to your machine's T-slots and connect the air supply to start saving setup time.

Plate Specifications

| Parameter | Specification |

|---|---|

| Plate Material | Hardened Stainless Steel |

| Flatness / Parallelism | ≤0.005mm |

| Standard Sizes (L x W) | Refer to catalogue |

| Integrated Modules | 1, 2, 4, or more, depending on plate size |

| Module Spacing | Standard 52mm, 96mm, 200mm grids, or custom patterns |

| Mounting System | Designed for standard T-slot tables or direct mounting |

| Surface Treatment | Corrosion-resistant coating |

Built as a Rock-Solid Foundation

The Nextas Zero-Point Clamping Plate serves as the crucial link between your machine tool and your workholding. Each plate is meticulously crafted from high-quality, stress-relieved steel or aluminum and precision-ground to achieve exceptional flatness and parallelism. This ensures that the micron-level accuracy of the integrated zero-point modules is perfectly transferred to your workpiece. The plates feature a standardized grid pattern (e.g., 52mm/96mm) and integrated plumbing for pneumatic actuation, making setup clean, simple, and incredibly fast.

52mm/96mm Industry-Standard Module Design

The manual zero point plate adopts a 52mm/96mm industry-standard module design, ensuring strong compatibility with global CNC machining tooling systems. This standardization avoids custom adaptation troubles, enabling seamless integration into both small workshops and large manufacturing setups. The two module sizes meet different workpiece weight and size needs, boosting flexibility in diverse machining tasks. With widely available spare parts, it simplifies maintenance and replacement. For businesses valuing consistency, this design cuts downtime from incompatible tooling, enhancing overall operational efficiency.

Compatibility with Self-Centering Vise: Over 90% Setup Time Cut

A key advantage of the manual zero point plate is its perfect compatibility with self-centering vises, which reduces workpiece setup time by over 90%. Traditional setups need repeated manual alignment, which is time-consuming and error-prone, harming part quality. When paired with a self-centering vise, the plate uses pre-set zero references and auto-centering, letting operators fix workpieces in seconds. This is vital for high-mix, low-volume production with frequent job changes, as it increases machine utilization and output while maintaining precision.

Versatile for Vertical/Horizontal MCs & 3/4/5-Axis Systems

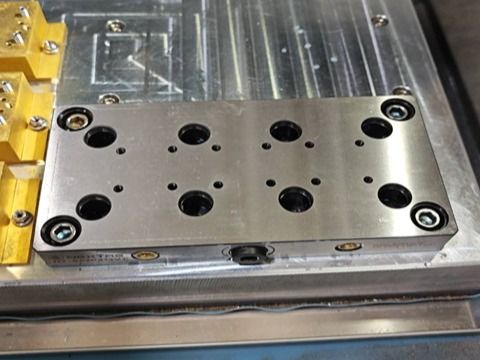

The manual zero point plate is highly versatile, fitting vertical/horizontal machining centers (VMCs/HMCs) and 3-axis, 4-axis, 5-axis CNC systems. In vertical machining, it stabilizes workpieces for milling, drilling, and tapping. In horizontal setups, it uses gravity to support longer/heavier workpieces. For complex 4/5-axis tasks like contouring, its precise alignment ensures quality. It serves industries like automotive, aerospace, and medical device manufacturing, eliminating the need for multiple specialized tools, reducing costs, and simplifying inventory management.

Horizontal Machining Centers (HMCs)

Use clamping plates as the base for tombstone fixtures, allowing you to prepare and load an entire multi-part setup offline and swap it into the machine in minutes.

Vertical Machining Centers (VMCs)

Equip your VMC with a clamping plate to rapidly switch between different vises, 4th-axis rotary tables, or custom job-specific fixtures without lengthy re-alignment procedures.

Automated Pallet Pools

Our clamping plates are the ideal foundation for automated pallet systems. Their robustness and standard interface ensure reliable, repeatable exchanges by robotic loaders 24/7.

CMM & Inspection

Transfer a workpiece directly from the CNC to the CMM on the same pallet, using an identical clamping plate as the reference. This eliminates re-fixturing errors and ensures consistent measurement.

See It In Action

Rapid Pneumatic Clamping Action

Experience the satisfying speed and power of our pneumatic zero-point clamping. With the press of a button, the system engages with immense force and perfect repeatability, locking the fixture securely. This is the core of our quick-change technology, engineered for reliability in the most demanding CNC production environments.

Case Study

Frequently Asked Questions

01 How does a zero-point plate reduce setup time vs. traditional T-slots?

02 What is the typical repeatability I can expect from this clamping plate?

03 What's the difference between a steel and an aluminum clamping plate?

04 What maintenance is required for the integrated pneumatic modules?

05 Can I use this plate for inspection on a CMM as well?

06 Are these plates compatible with my existing self-centering vises?

Resources & Downloads

Related Products

Zero-Point Systems

The core clamping modules that provide the locking force and precision.

View Details →

Pneumatic Vise

Ideal for automated production lines, offering fast and stable clamping.

View Details →

R-Series Chuck

High-precision pneumatic chuck for stationary and rotary applications.

View Details →