Please enter your email address to receive the product catalog directly in your inbox.

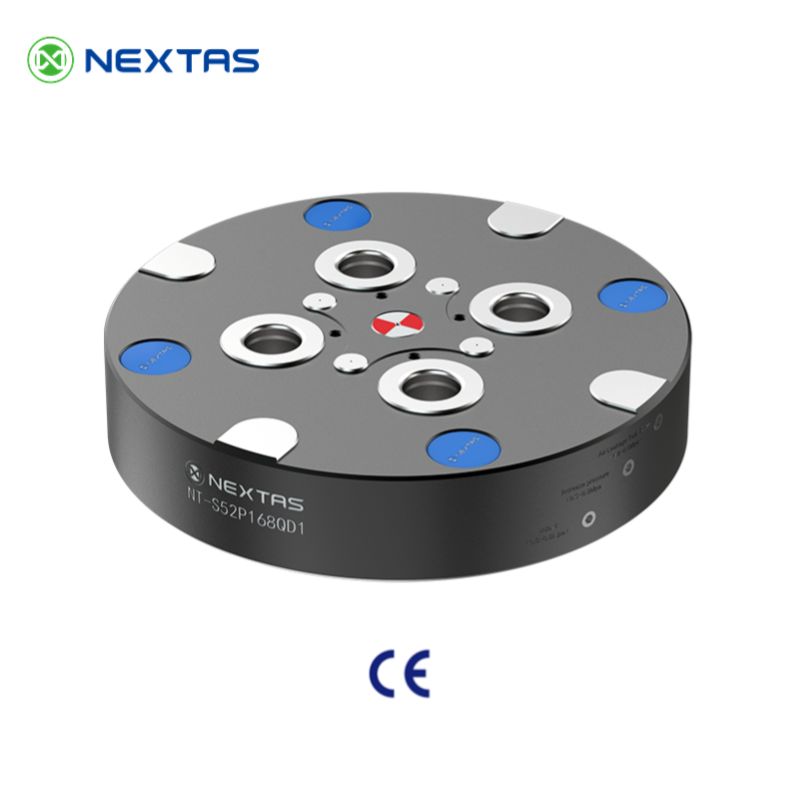

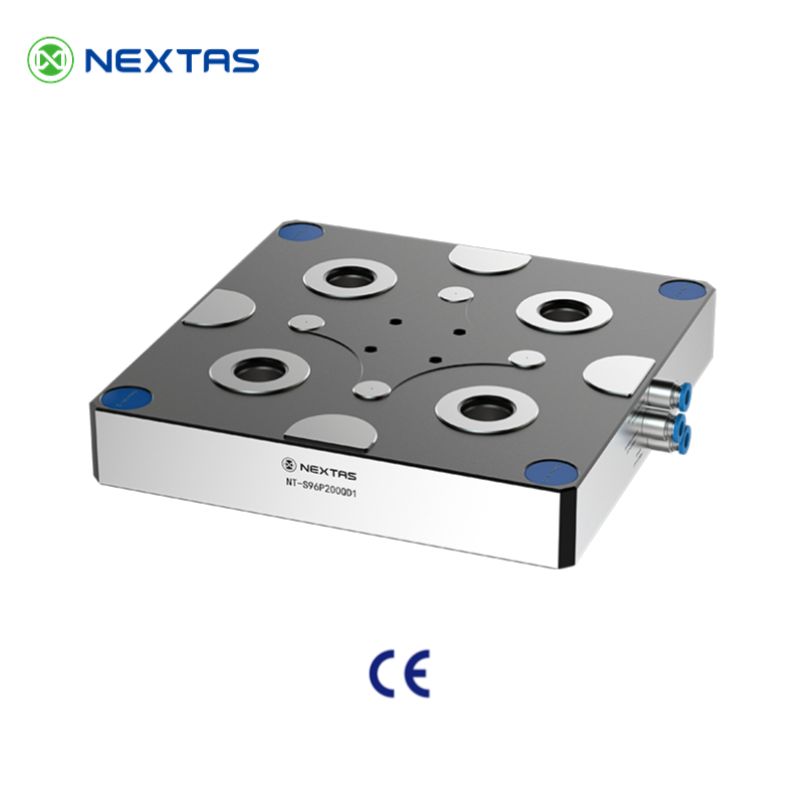

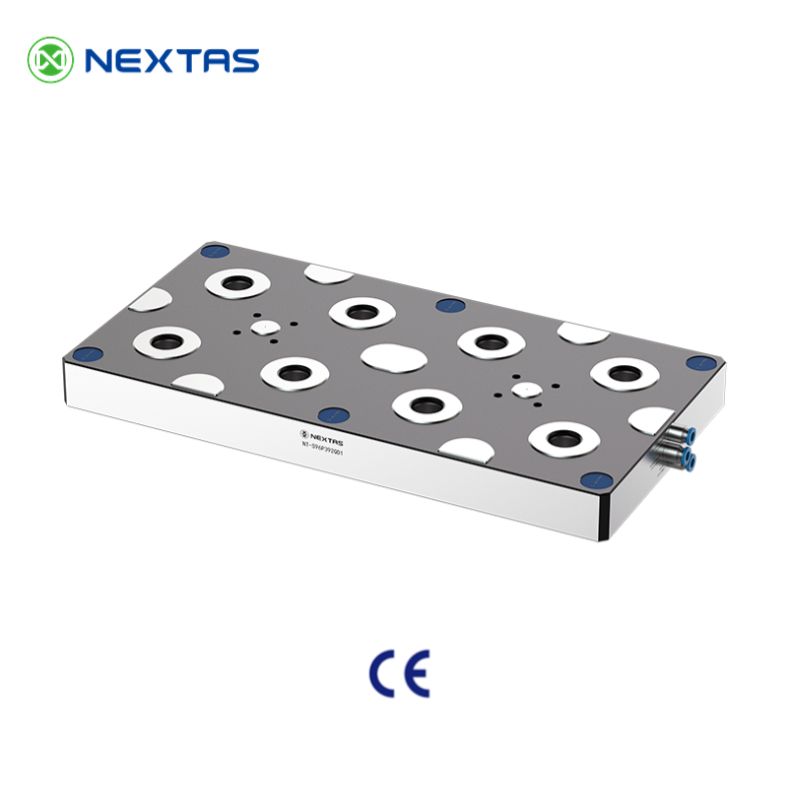

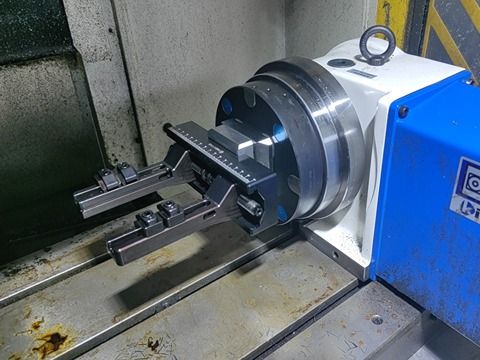

Pneumatic Zero Point Plate

The Foundation for Automation.

Unlock maximum efficiency with the Nextas Pneumatic Zero Point Plate. This system creates a precise and repeatable foundation on your machine table, allowing fixtures and workpieces to be changed in seconds, not hours. By standardizing your setup process, you drastically reduce downtime, increase machine utilization, and pave the way for seamless automation.

Core Advantages

- Micron-Level Repeatability: Guarantees a repeat positioning accuracy of ≤0.005mm, eliminating realignment.

- Massive Clamping Force: Failsafe spring mechanism ensures rigid clamping even during heavy cutting.

- Seconds to Changeover: Pneumatic unlocking for near-instantaneous clamping, minimizing downtime.

- Automation Ready: Integrated ports for air sensing and cone cleaning for reliable robotic integration.

Main Features

- Patented New Product: An innovative, globally debuted product with unique technological advantages.

- Standard Compatibility: Adopts 52/96mm standard pitch for universal compatibility with other workholding products.

- Ultra-High Precision: Repeat positioning accuracy of less than 0.005mm for the most demanding tasks.

- Powerful Performance: Clamping force exceeds 20KN, with a lifting capacity over 330KG.

- Enhanced Reliability: Equipped with air tightness testing and cleaning functions for robust operation.

- Strengthened Clamping: Air pressure boosting function strengthens clamping force, improving stability.

- Convenient Operation: Automatically lifts the vice/pallet when unlocked for efficient operation.

Technical Specifications & Design

Engineered for precision, durability, and seamless integration into automated workflows.

Key Technical Parameters

| Parameter | Specification (Model: NPZP-150) |

|---|---|

| Pull Stud Compatibility | Standard 52mm / 96mm pitch |

| Repeatability | ≤0.005 mm |

| Clamping Force (per module) | 25 kN (with turbo function) |

| Actuation | Pneumatic unlock, Spring lock (Failsafe) |

| Operating Pressure | 6 bar |

| Automation Functions | Clamping/unclamping check, Cone cleaning |

| Body Material | Hardened Stainless Steel |

| Weight (4-module plate) | ~25 kg |

Precision by Design

The Nextas system uses pneumatic pressure to unlock, while powerful internal springs drive the clamping slides. This pulls positioning studs into tapered locating cones, creating a secure, vibration-dampening connection with a precisely defined zero point. The "normally locked" state ensures force is maintained even if air pressure is lost, guaranteeing safety.

Built for the Modern Shop Floor

Constructed from hardened, corrosion-resistant stainless steel, our zero point plates are built to withstand the rigors of any manufacturing environment. The system is fully sealed to protect the internal mechanism from chips, coolant, and other debris. Integrated air-blast channels automatically clear the locating cones of any contaminants before clamping, ensuring that the ≤.005mm repeatability is maintained every single time.

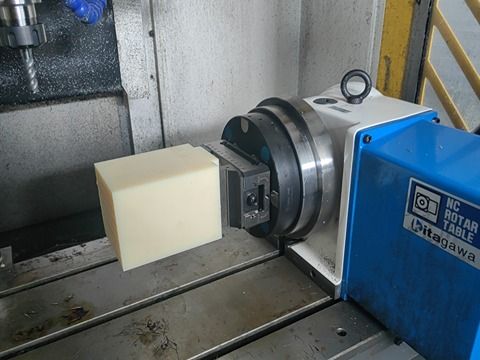

The Gateway to Unattended Machining

By providing a common, high-precision interface on all your machines—from milling centers to EDMs to CMMs—the zero point system unlocks true process optimization. Palletized workpieces can be moved between operations by a robot, clamped with repeatable accuracy, and machined without operator intervention. This is the key to lights-out manufacturing.

Automation Integration

Nextas Pneumatic Zero Point Plate streamlines robot automation: it synchronizes with robotic arms for fast, error‑free workpiece or fixture swaps, drastically reducing manual setup time. Its stable clamping — providing over 20 kN of force — allows robots to safely handle heavy loads.

The precision interface ensures consistent accuracy so robots can repeat tasks without any re‑calibration. By linking robots to machining tools for smooth, unattended factory workflows, the system enables 24/7 lights‑out operation.

Versatile Application Scenarios

From single-machine efficiency to fully automated production lines, our system adapts to your needs.

Horizontal Machining Centers (HMC)

Perfect for pallet pools on HMCs. Prepare fixtures offline and load them onto the pallet changer, ensuring the machine is always cutting.

5-Axis Machining

Raises the workpiece off the table, providing superior tool access to all five sides of a part, eliminating multiple setups.

Automated Production Cells

The core of any flexible manufacturing system (FMS). Robots can reliably exchange entire fixtures for unattended, 24/7 production.

Inspection & Quality Control

Use the same zero point reference on your CMM. Transfer parts directly from CNC to inspection without re-clamping, eliminating errors.

Proven Results: Case Study

Our system enables rapid changeover in industrial manufacturing, boosting changeover efficiency by over 90% and production efficiency by more than 30%.

Frequently Asked Questions

What is a Pneumatic Zero Point Plate and who is it for?

What are the key specifications?

Which machines is it compatible with?

How is the Pneumatic Zero Point Plate installed?

Where can I get CAD files or technical documentation?

What's the difference between pneumatic unlock and pneumatic clamp?

How does the "turbo function" for clamping force work?

What kind of maintenance do these pneumatic plates require?

Can this plate be used in an environment with heavy coolant and chips?

What is the advantage of the 52/96mm standard pitch?

Resources & Downloads

Related Products

Automatic Pallet Changer

Integrate for fully automated production cycles and increased throughput.

View Details →>

E-Series Chuck

High-precision pneumatic chuck for automated lathe and milling applications.

View Details →>

R-Series Chuck

Robust chucking solution for heavy-duty turning and stationary clamping.

View Details →>