Szybkie Prototypowanie Precyzyjne

Precyzja ±0,002 mm dzięki materiałom klasy premium

Od materiałów najwyższej jakości z kompletnymi raportami z inspekcji po najnowocześniejsze centra obróbcze CNC — Nextas dostarcza prototypy z dokładnością na poziomie mikronów. Nasze wewnętrzne procesy obróbki cieplnej i wykańczania powierzchni zapewniają, że każdy element spełnia rygorystyczne normy przemysłowe przy zachowaniu efektywności kosztowej.

Kluczowe zalety

- Materiały premium i kontrola: Pozyskujemy wyłącznie wysokiej jakości materiały i dostarczamy pełne raporty z kontroli, aby zapewnić identyfikowalność i niezawodność każdego prototypu.

- Precyzja na poziomie mikronów: Wykwalifikowani operatorzy i zaawansowane urządzenia CNC osiągają tolerancje ±0,002 mm dla najbardziej wymagających zastosowań.

- Specjalistyczna obróbka cieplna: Kontrolowane procesy cieplne tworzą części o wysokiej twardości, zaprojektowane tak, aby wytrzymać ekstremalne obciążenia i zużycie.

- Kompleksowe wykończenie powierzchni: Oferujemy piaskowanie, anodowanie, chromowanie czarne oraz powłoki DLC, aby uzyskać pożądane właściwości funkcjonalne i estetyczne.

- Produkcja własna i kontrola kosztów: Pionowo zintegrowane zakłady umożliwiają ścisłą kontrolę kosztów i zapewniają konkurencyjne ceny prototypów bez kompromisów jakościowych.

- Rygorystyczna kontrola wyjściowa: Każda partia jest dokładnie sprawdzana, aby upewnić się, że finalne prototypy spełniają lub przewyższają Twoje wymagania.

(5).png?updatedAt=1755182523411)

Światowej klasy sprzęt i materiały

Nextas obsługuje zaawansowane 5-osiowe centra obróbcze, precyzyjne tokarki, frezarki pionowe oraz szlifierki współrzędnościowe od czołowych producentów japońskich i amerykańskich. W połączeniu z materiałami premium i rygorystyczną kontrolą wejściową, nasze prototypy powstają na najlepszym możliwym fundamencie.

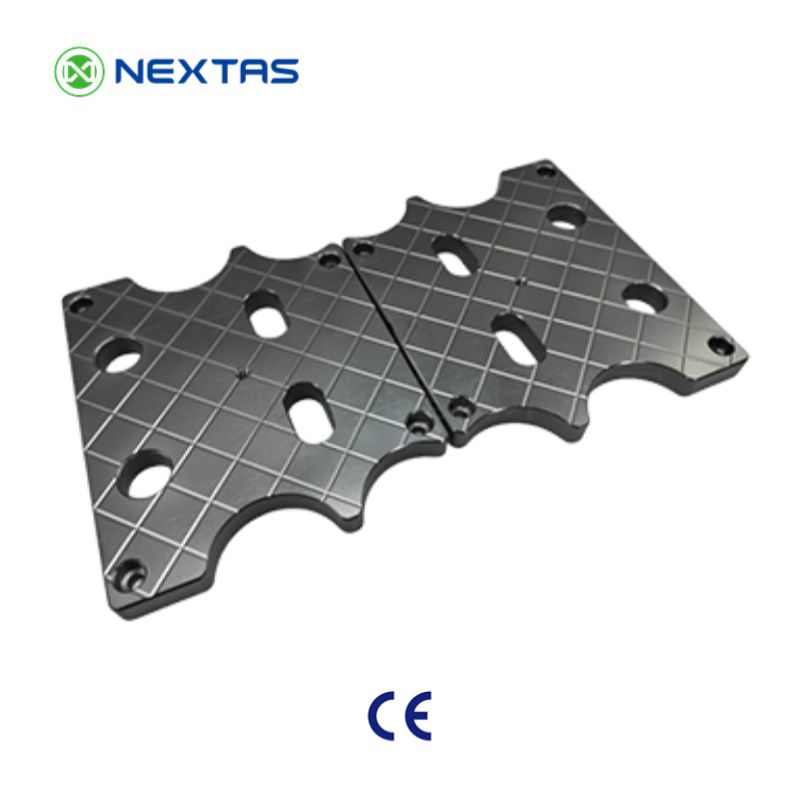

Precyzyjnie obrabiane prototypy

Nasi doświadczeni operatorzy wykorzystują najnowocześniejszy sprzęt CNC do tworzenia skomplikowanych geometrii z tolerancjami rzędu ±0,002 mm. Każdy element i gwintowany otwór jest precyzyjnie obrabiany, aby spełnić Twoje dokładne specyfikacje.

Wysoka stabilność i dokładność

Każdy prototyp jest projektowany z myślą o stabilności i trwałości. Solidne konstrukcje z wieloma punktami mocowania i wzmocnionymi sekcjami zapewniają integralność wymiarową podczas testów i integracji.

Wszechstronność i wykończenie powierzchni

Oprócz obróbki mechanicznej oferujemy specjalistyczną obróbkę cieplną oraz szeroką gamę wykończeń powierzchni — piaskowanie, anodowanie, chromowanie czarne oraz powłoki węglowe DLC (Diamond-Like Carbon) — aby uzyskać pożądane właściwości funkcjonalne i estetyczne.

Najczęściej Zadawane Pytania (FAQ)

01 Czym jest Szybkie Prototypowanie Precyzyjne i dla kogo jest przeznaczone?

02 Jakie są kluczowe specyfikacje Szybkiego Prototypowania Precyzyjnego?

03 Z jakimi maszynami lub procesami jest kompatybilne?

04 Jak montowane lub ustalane są prototypy?

05 Gdzie mogę uzyskać pliki CAD lub dokumentację techniczną?

06 Jakich materiałów używacie do szybkiego prototypowania?

07 Jaki jest typowy czas realizacji projektu prototypowego?

08 Jak zapewniacie precyzję ±0,002 mm?

Zasoby i pliki do pobrania

Powiązane Produkty

Uchwyt Serii E

Wszechstronny i precyzyjny uchwyt do szerokiego zakresu zautomatyzowanych zastosowań tokarskich.

Zobacz szczegóły →

Uchwyt Serii R

Zapewnia mocne, spójne mocowanie dla ciężkich operacji toczenia i frezowania.

Zobacz szczegóły →

Automatyczny Zmieniacz Palet

Drastycznie skraca czas przezbrojenia i zwiększa czas pracy maszyny dzięki w pełni automatycznej wymianie palet.

Zobacz szczegóły →