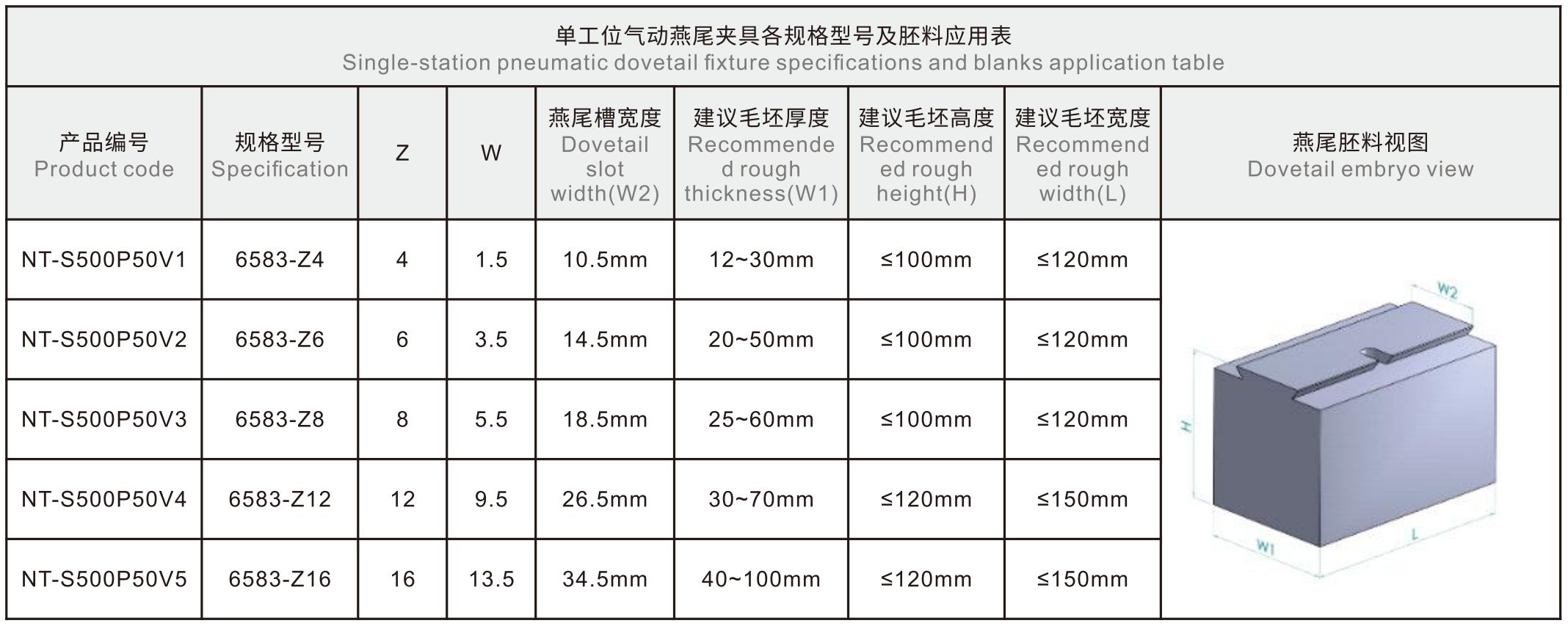

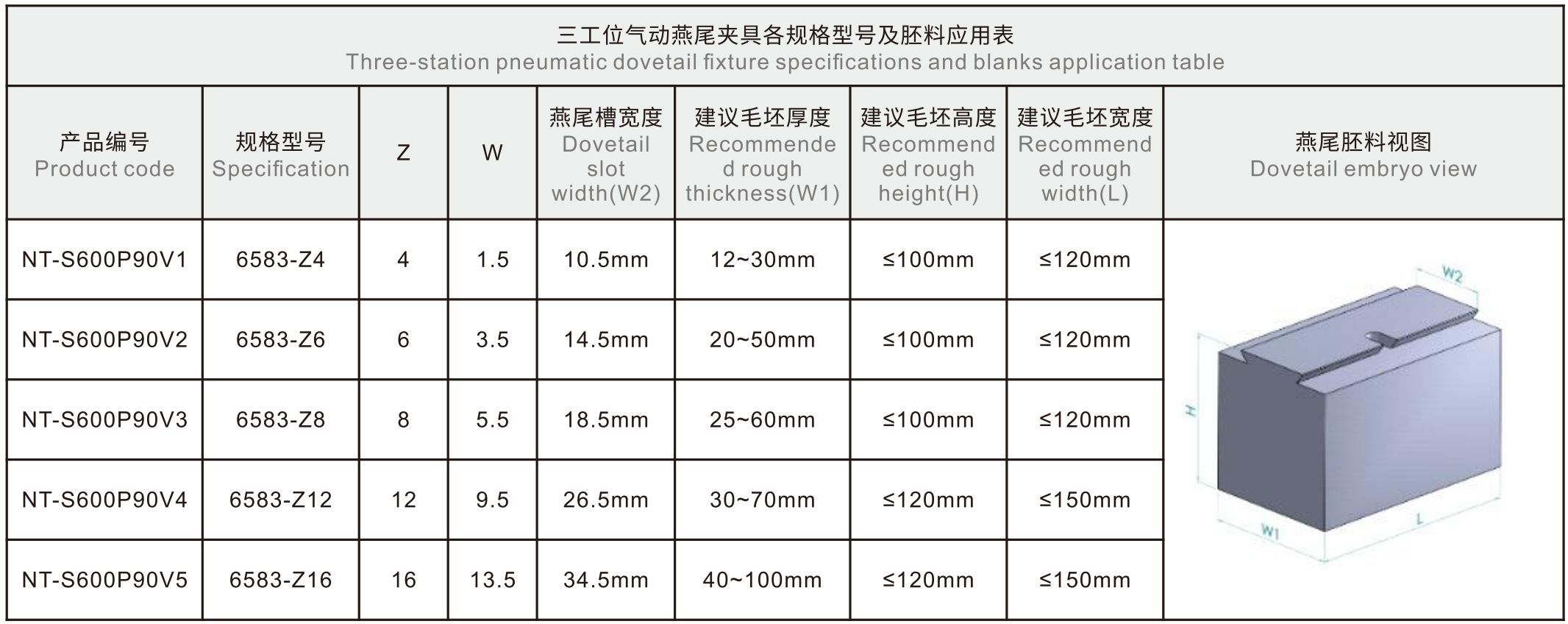

Modular Dovetail Fixture

Rigid 5-Side Clamping for 52 & 96 Systems

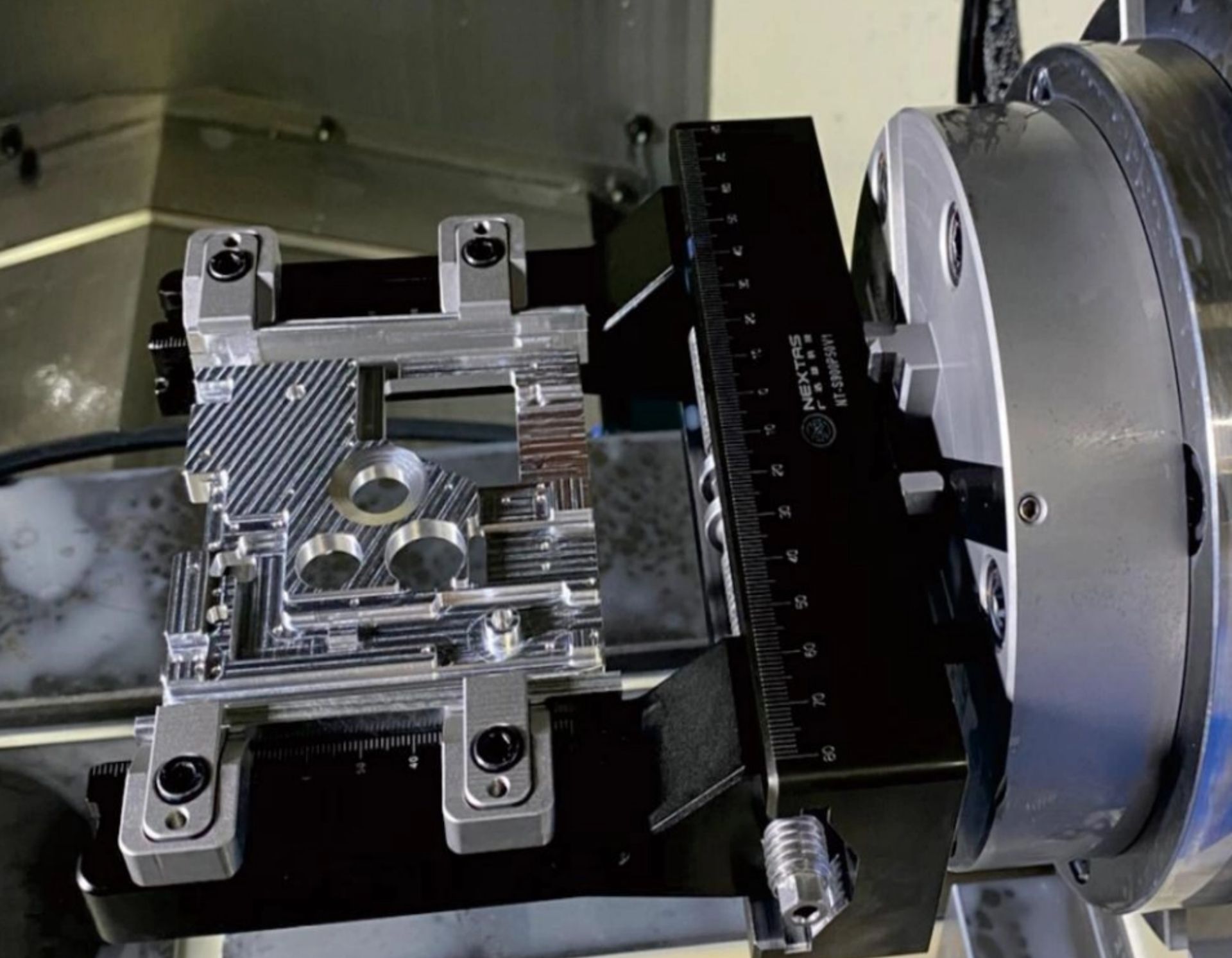

Engineered for high-speed five-axis machining, the Nextas dovetail fixture securely grips the workpiece on a small 45° profile, exposing five faces for machining while minimizing material waste. Precision locating pins ensure repeatable positioning, and the modular 52 / 96 mm base integrates seamlessly with zero-point plates and quick-change systems for lightning-fast setups.

Core Advantages

- Five-Side Machining Access: Grips stock on a minimal 45° dovetail profile to expose five faces for machining, allowing more part to be milled per setup and reducing material waste.

- Superior Clamping Force: The 45° dovetail design produces high clamping force and rigid stability, resisting cutting vibrations and preventing slippage.

- High Precision & Repeatability: Precision locating pins and ground surfaces ensure repeatable positioning and eliminate workpiece movement.

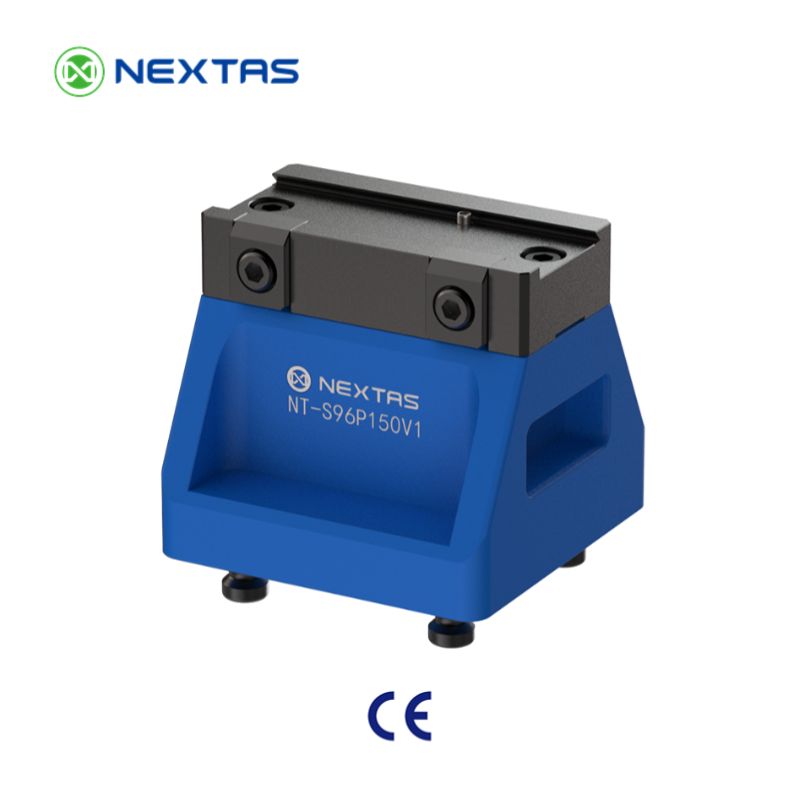

- Modular 52 / 96 Integration: Standard 52 mm and 96 mm patterns integrate with zero-point systems and quick-change plates for flexible mounting and rapid changeovers.

- Lightweight & Durable: Aerospace-grade aluminium body with stainless steel inserts provides high strength, reduced weight and long-term stability.

- Versatile & Automation Ready: Supports a wide range of materials and is ideal for high-mix production and robotic automation thanks to quick setups and a compact footprint.

Technical Specifications

Both 52 mm and 96 mm dovetail fixtures conform to industry-standard zero-point mounting patterns. Detailed dimensional drawings are provided below for quick reference.

Five-Side Machining Efficiency

The dovetail fixture clamps the workpiece along a small 45° dovetail, leaving the top, front, back and two sides completely unobstructed for cutting. This design enables true five-side machining in a single setup and reduces the extra material normally required for gripping, saving both time and raw material costs.

Precision & Repeatability

Each dovetail fixture is fitted with precision locating pins and ground reference surfaces to eliminate slide and ensure high repeatability when swapping parts. Combined with the rigid dovetail geometry, this guarantees consistent machining accuracy and surface finish.

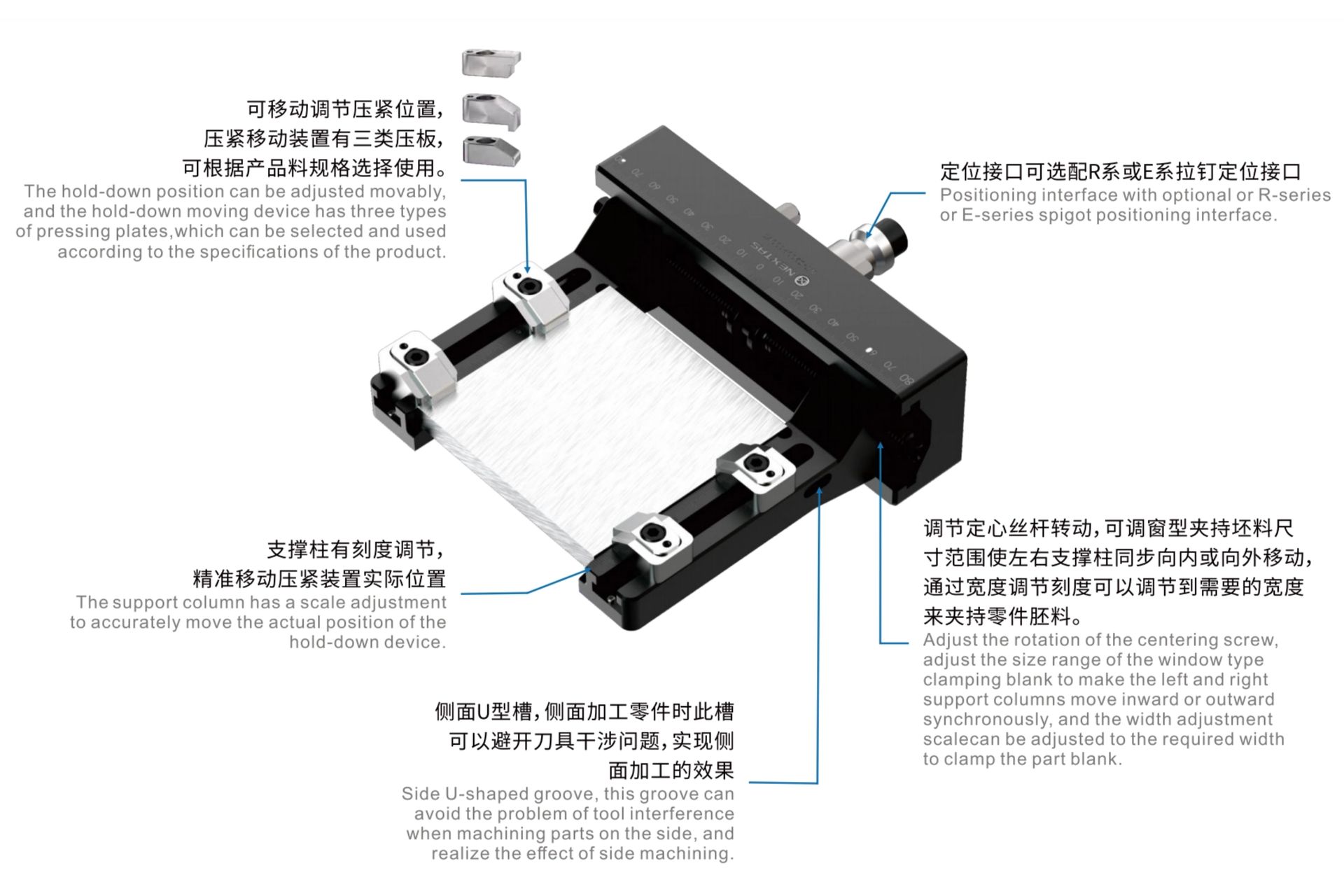

- Patented design for small plate processing on 3/4/5-axis machines.

- Adjustable clamping position with selectable pressing plates.

- Support column with scale adjustment for precise hold-down placement.

- Side U-shaped groove avoids tool interference during side machining.

- Optional 3R or Erowa spigot positioning interfaces.

Modular & Zero-Point Compatible

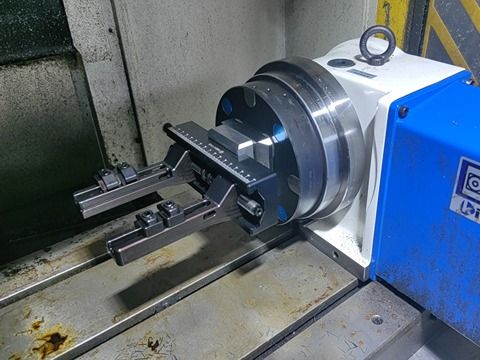

The base of the fixture is machined to industry-standard 52 mm and 96 mm patterns, making it directly compatible with zero-point clamping plates, quick-change systems and automation pallets. This modularity streamlines setup changes and allows multiple fixtures to be mounted in high-density arrays for increased throughput.

Applications & Use Cases

Case Study: Industrial Automation

The dovetail fixture pairs seamlessly with the pneumatic zero-point plate, enabling fast, precise clamping of thin-sheet products in industrial automation. It slashes setup time, ensures stable machining, and boosts machining efficiency by over 30%.

Complex 5-Axis Machining

Ideal for titanium and aerospace parts requiring full-surface access. The dovetail fixture exposes five faces, allowing intricate features to be milled in one setup without repositioning.

Quick Change & Automation

With standard 52 / 96 mm mounting patterns, fixtures drop into zero-point plates for lightning-fast swaps. Combine with robotic pallet changers for fully automated, high-density production lines.

Material Versatility

From aluminium to hardened steel, the dovetail fixture securely holds a variety of materials. Its balanced design reduces distortion and makes it perfect for prototyping as well as series production.

Frequently Asked Questions

How much material do I need to prepare for the 45° dovetail?

What is the primary difference between the 52 mm and 96 mm dovetail fixtures?

Can I use these dovetail fixtures on a 3-axis or 4-axis machine?

How does this dovetail fixture compare to a self-centering vise for 5-side machining?

What kind of maintenance do these fixtures require?

Are the clamping components and locating pins replaceable?

Related Products

E-Series Chuck

A versatile and precise chuck for a wide range of automated turning applications.

View Details →>

R-Series Chuck

Provides powerful, consistent clamping for heavy-duty turning and milling operations.

View Details →>

Automatic Pallet Changer

Drastically reduce setup time and increase machine uptime with fully automated pallet changes.

View Details →>