Customized Hydraulic Fixture System

High-Performance Clamping for Automated Manufacturing

Nextas Hydraulic Fixture Systems are engineered to meet the rigorous demands of high-volume, high-precision production. Tailored to your specific workpiece and machining process, our fixtures provide powerful, consistent clamping force, exceptional rigidity, and seamless integration with automated loading systems, dramatically reducing cycle times and improving overall equipment effectiveness (OEE).

Core Advantages

Engineered for performance, reliability, and seamless automation integration.

Unmatched Clamping Force

Delivers high, evenly distributed hydraulic pressure for secure workholding, eliminating slippage even during aggressive cutting.

Consistent High Precision

Engineered for exceptional positioning repeatability (≤.005mm), ensuring every part is machined to exact specifications.

Designed for Automation

Features integrated ports and sensors for clamp/unclamp confirmation, enabling seamless use with robotic and FMS systems.

Durable & Robust Construction

Built from high-grade, heat-treated alloy steel to withstand the harshest production environments and ensure long-term reliability.

Collaborative Design, Precision Execution

Our process begins with your component. We collaborate closely with your engineering team to understand machining requirements, part geometry, and production goals to build a truly bespoke solution.

Advanced Hydraulic System

The core of our fixture is a high-pressure hydraulic system featuring hardened steel components and leak-proof seals. This ensures reliable, maintenance-free operation over millions of cycles. The system is designed for rapid clamping and unclamping, minimizing non-productive time.

Modularity and Adaptability

Our fixtures are often designed with modularity in mind. Interchangeable clamping elements and locators allow a single fixture base to accommodate a family of parts, providing a cost-effective and flexible workholding solution for the future.

Technical Specifications

Note: These are typical specifications. All parameters are customized based on the specific application requirements.

| Parameter | Typical Specification Range |

|---|---|

| Positioning Repeatability | ≤0.005 mm |

| Clamping Force | 5 kN - 200 kN (application dependent) |

| Operating Hydraulic Pressure | 10 - 70 MPa (1450 - 10150 PSI) |

| Fixture Body Material | High-Grade Alloy Steel or Aircraft-Grade Aluminum |

| Clamping Components Material | Hardened Tool Steel (HRC 58-62) |

| Actuation | Single-acting or Double-acting Hydraulic Cylinders |

| Automation Interface | Hydraulic quick-couplings, Electrical sensors (PNP/NPN) |

Proven Success in Demanding Industries

Our hydraulic fixtures are trusted by leaders in automotive, aerospace, and heavy machinery for their most critical machining operations.

Automotive Powertrain

The industry standard for machining engine blocks, cylinder heads, and transmission cases. Our fixtures provide the rigidity and precision needed to hold tight tolerances on critical features, ensuring performance and reliability.

Aerospace & Defense

From structural airframe components to complex turbine blades, our fixtures securely hold thin-walled or exotic materials without distortion. We provide proven solutions for 5-axis machining of titanium, Inconel, and high-strength aluminum alloys.

Heavy Machinery & Energy

We design robust fixtures for large workpieces like hydraulic manifolds, valve bodies, and gear housings. Our solutions are built to handle heavy parts and high metal removal rates, maximizing throughput in demanding production environments.

Resources

Access technical documents or request specific CAD models for your project.

Frequently Asked Questions

What is a Customized Hydraulic Fixture System?

It is a bespoke workholding solution for CNC machining that uses hydraulic power for strong, consistent clamping, ideal for high-volume, precision manufacturing in industries like automotive and aerospace.

What are its key specifications?

Typical specs include: Repeatability ≤0.005 mm, Clamping Force 5-200 kN, and Operating Pressure 10-70 MPa. Materials are high-grade alloy steel and hardened tool steel for durability.

Which machines are compatible?

The system is compatible with a wide range of CNC machines, including 3-axis to 5-axis machining centers, and integrates with automation systems like robotic loaders and zero-point systems.

Where can I get CAD files?

For specific STEP/IGES 3D models or 2D drawings for your project, please contact us through our consultation form.

How do you ensure clamping force if hydraulic pressure is lost?

Safety is paramount. Our fixtures are designed with hydraulic lock-in valves (check valves) and/or mechanical locking mechanisms. This ensures that even in the event of a sudden loss of hydraulic pressure, the fixture maintains its full clamping force, preventing workpiece ejection and protecting the machine and operator.

What is the typical lead time for a custom fixture?

Lead time varies with complexity, but a typical project follows this timeline: 1-2 weeks for initial design consultation and concept approval; 2-3 weeks for detailed engineering and simulation; and 4-6 weeks for manufacturing, assembly, and quality assurance. We work transparently to meet your production deadlines.

Can your fixtures clamp multiple parts at once?

Yes, multi-part clamping is one of our specialties. We design high-density fixtures that can securely clamp multiple workpieces in a single setup. This dramatically reduces cycle time per part and maximizes your machine's spindle uptime, making it ideal for high-volume production.

How do you manage chip and coolant in the fixture design?

This is a critical part of our design. We incorporate features like sealed clamping mechanisms, angled surfaces for chip shedding, and integrated high-pressure air/coolant ports. This prevents chip buildup in critical locating areas, ensures consistent clamping, and reduces manual cleaning, which is essential for automated cells.

Related Solutions

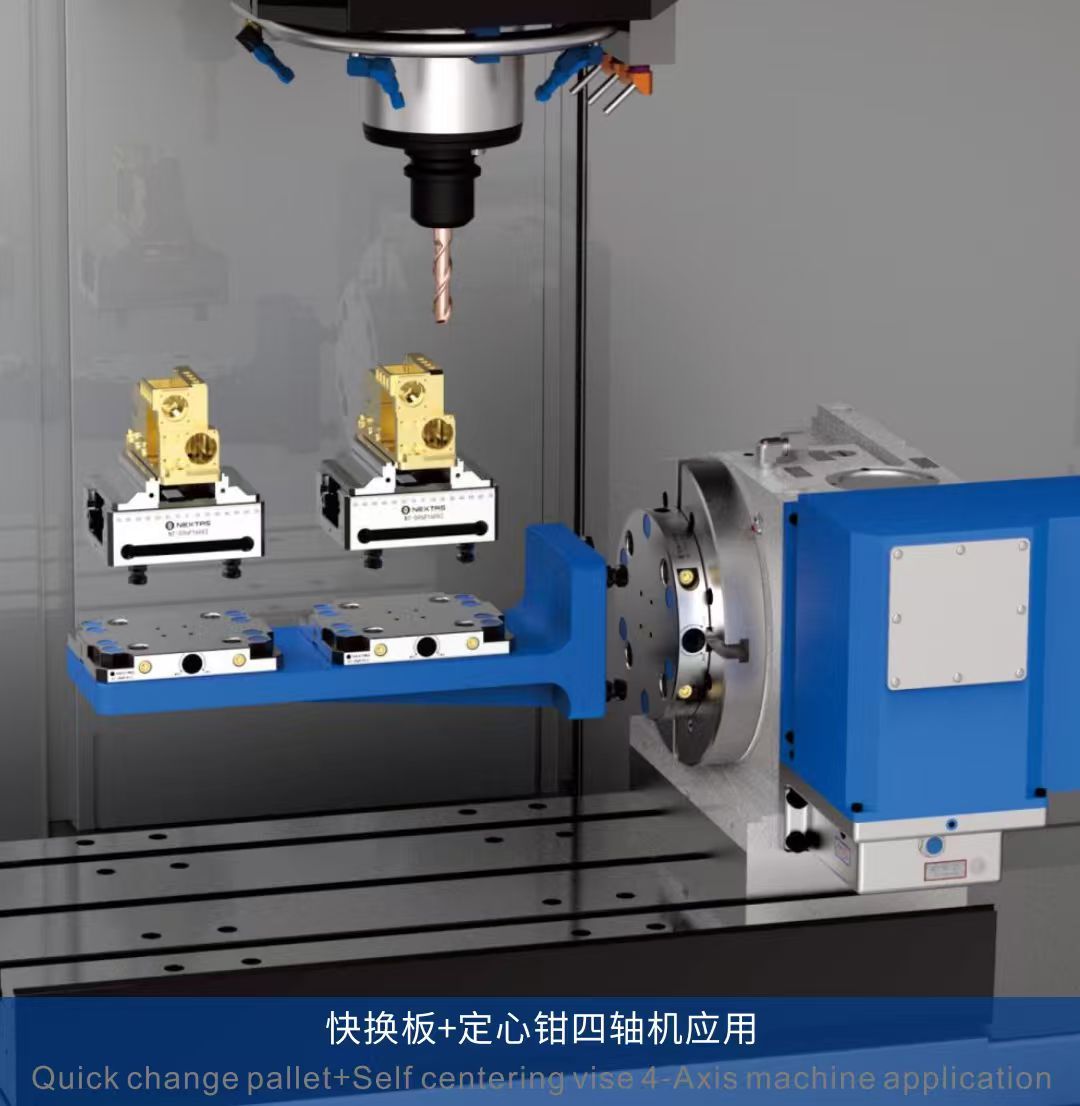

Zero Point Clamping System

The perfect base for our hydraulic fixtures, enabling rapid changeovers with ±0.002mm repeatability.

View Details →>

Self-Centering Vise

Ideal for 5-axis machining of smaller, prismatic parts with high precision.

View Details →>

Automatic Pallet Changer

Maximize machine uptime by integrating your hydraulic fixtures with our APC systems.

View Details →>